どのような場合に減-切削PCBセパレータープロジェクト

When to use a down-cutting PCB separator is a common question for engineers and manufacturers. Down-cutting PCB separators are specialized machines designed to safely and efficiently separate printed circuit boards without damaging components. If your project involves small-batch or high-mix production, understanding the right applications is critical. ⚡ Ideal for High-Component PCBs Down-cutting PCB separators are particularly suitable for PCBs with high components, up to 45mm in height. Unlike traditional depaneling methods, they reduce the risk of bending or damaging tall components. High-component boards often require precise handling. A down-cutting separator ensures a smooth cut while keeping the integrity of sensitive components intact. 💨 Cleaner Dust Collection with Lift-and-Drop Suction […]

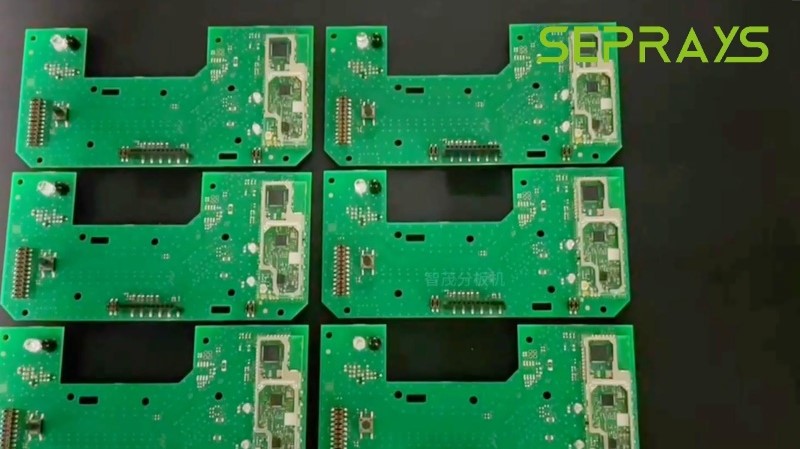

などがある場合粉塵除去して基板回路基板? Sepraysフライスカッター基板Depanelerばたい!

When separating PCB circuit boards, dust can be more than just an inconvenience. It can harm your products, equipment, and even your team’s health. The Seprays Milling Cutter PCB Depaneler is designed to solve these problems efficiently. 🌫 Understanding the Dust Problem in PCB Separation Dust from PCB separation isn’t just harmless debris. In production, dust can slow processes, reduce quality, and require extra cleaning steps. It can even contaminate cleanroom environments. 💡 How Seprays Milling Cutter PCB Depaneler Controls Dust The Seprays Milling Cutter PCB Depaneler integrates advanced dust collection technology. These features work together to keep the work area clean, protect your boards, and extend machine life. ⚙ […]

.png)