なぜ低ストレスが重要になるので基板Depaneling?

🛠 Low stress in PCB depaneling is critical for maintaining product quality and improving manufacturing efficiency. During the separation of individual boards from a panel, excessive mechanical stress can damage components and reduce overall yield. Understanding why low stress matters helps manufacturers choose the right depaneling solution for sensitive electronics. ⚙ What is Low-Stress PCB Depaneling? Low-stress PCB depaneling refers to separating printed circuit boards while minimizing mechanical forces that could affect the board or components. Modern depaneling machines, such as milling cutter depanelers, use precise cutting technology to reduce vibrations and prevent micro-cracks in solder joints. Key goals include: 💎 Protecting Components from Damage High stress during depaneling can […]

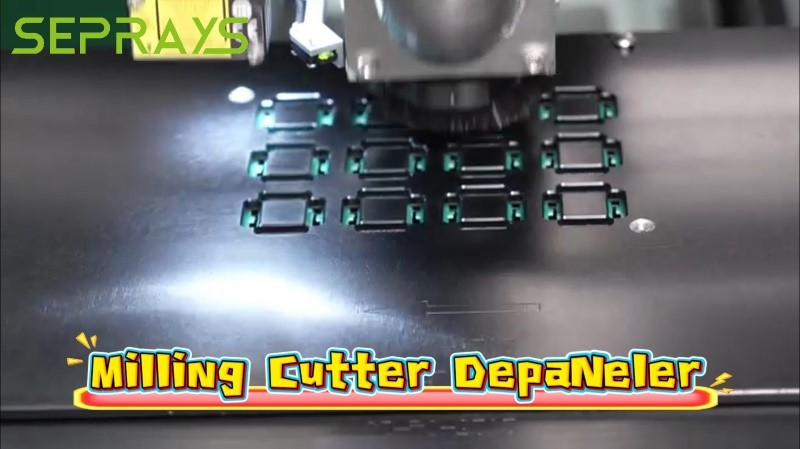

精密基板Depaneling–低ストレス,ミラーズエッジ、高い利回り

📏 Precision PCB depaneling is the key to achieving consistent quality in modern electronics manufacturing, whether producing consumer electronics, medical devices, or automotive components. A clean, stress-free cut ensures higher yields and improved reliability. 🛠 What is Precision PCB Depaneling? Precision PCB depaneling is the process of separating individual printed circuit boards from a larger panel with minimal mechanical stress. Advanced depaneling methods—such as milling cutter machines—can achieve cuts with ±0.05 mm accuracy. The goal is simple: ⚙ Why Low-Stress Matters in PCB Separation During PCB manufacturing, stress applied during separation can cause: By using low-stress precision PCB depaneling equipment, manufacturers can: 💎 Mirror-Smooth Edges for Better Assembly A mirror-smooth […]

.png)