⚙ A PCB milling cutter depaneling machine is transforming how electronics manufacturers handle circuit board separation. Unlike manual tools or outdated methods, it offers clean edges, low stress, and high precision. By protecting components and improving overall yield, it has become an essential investment for companies across multiple industries.

🔧 What Is a PCB Milling Cutter Depaneling Machine?

A PCB milling cutter depaneling machine uses a high-speed spindle with specialized bits to cut through panelized circuit boards. Instead of snapping or punching, it follows programmed paths with exceptional accuracy.

This approach prevents cracking, solder joint stress, and damage to nearby parts. It allows manufacturers to separate boards safely, even when designs are complex or packed with sensitive components.

🛡 Why Component Protection Matters

Electronics today are smaller, thinner, and more fragile than ever. Manual separation often bends boards or causes micro-fractures that reduce reliability.

With a PCB milling cutter depaneling machine, boards stay intact. The cutting stress is minimal, meaning components near the edge remain secure. Protecting chips, capacitors, and connectors ensures fewer returns, less waste, and better product performance.

📈 How It Improves Yield

Yield is a key factor in any production line. Every damaged board equals lost revenue. By using automated milling, manufacturers see a higher pass rate and less rework.

The machine guarantees repeatable accuracy, keeping cuts within ±0.02 mm. Smooth edges reduce dust contamination, and automated alignment avoids operator error. More boards pass inspection, driving efficiency and profitability.

⚡ Benefits Over Other Methods

Compared to V-cut, punching, or manual breaking, the milling cutter method offers clear advantages:

- Cleaner, burr-free edges.

- Lower mechanical stress on PCBs.

- Capability to handle any shape, including irregular designs.

- Higher consistency in mass production.

These features make it the preferred option for industries demanding both quality and scale.

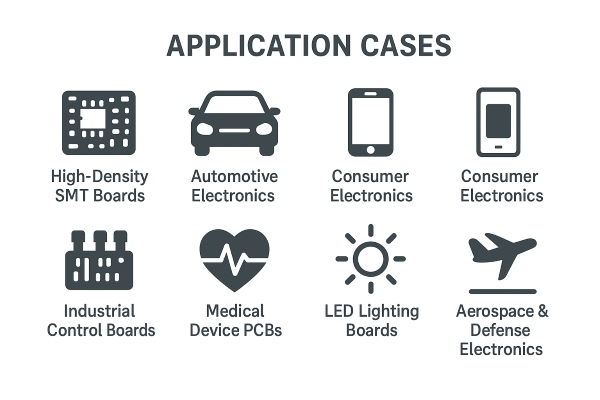

🚗 Applications Across Industries

の PCB milling cutter depaneling machine is widely used in:

- Automotive electronics for safety-critical systems.

- Medical devices where reliability is life-dependent.

- Consumer electronics such as smartphones and wearables.

- Telecom equipment for high-speed networking.

- LED lighting for large-volume panel separation.

Each sector benefits from precision, low stress, and scalable automation.

🌍 The Future of Depaneling

As PCB designs grow denser and thinner, the need for low-stress, dust-free cutting will continue to rise. Milling machines are adaptable and ready for evolving production demands. Manufacturers looking to stay competitive will rely more on this technology.

💡 Why Choose Seprays Group?

At Seprays Group, we specialize in advanced PCB milling cutter depaneling machines designed for high accuracy and low stress. Our systems deliver:

- Component protection with minimal cutting force.

- Improved yield through precise, repeatable performance.

- Integrated dust collection and ESD protection for long-term reliability.

- Flexible automation for both small and mass production.

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

📧 If you need support, please contact us today.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)