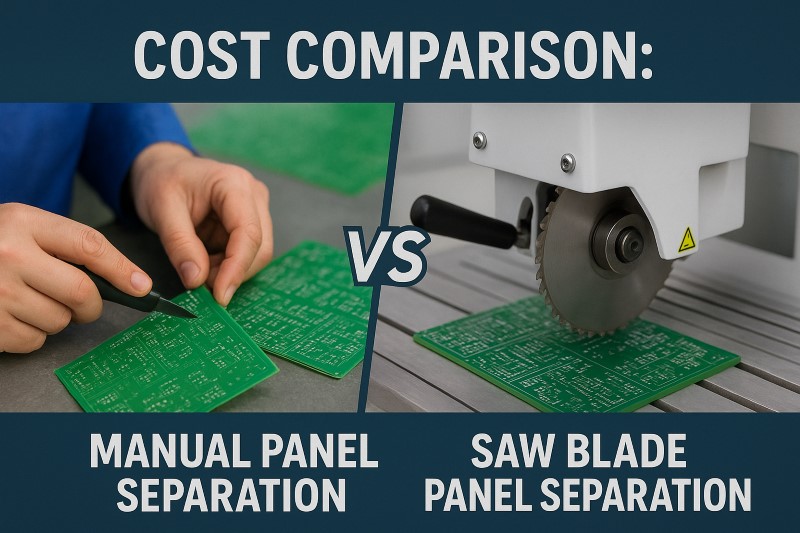

In the world of PCB depaneling, every manufacturer faces a common question: Should you continue with manual depaneling or switch to an automatic saw blade depaneling machine? While manual cutting may seem inexpensive at first glance, hidden costs often reveal a different story. Understanding these differences is crucial to optimizing production efficiency, minimizing board damage, and enhancing long-term profitability.

🔍 Understanding PCB Depaneling Methods

PCB depaneling is the process of separating individual circuit boards from a larger panel after assembly. Two of the most widely used methods are:

- Manual depaneling, typically done using hand tools such as cutters or small routers.

- Saw blade depaneling machines, which use high-speed rotating blades to separate boards with precision and consistency.

Both methods achieve the same purpose — but their efficiency, cost, and quality impact differ greatly.

🧰 Pain Points of Manual Depaneling

Many small or medium-scale manufacturers rely on manual depaneling due to low initial investment. However, manual cutting introduces several hidden challenges:

- High risk of cracks or stress marks on delicate PCBs.

- Inconsistent quality depending on operator skill and fatigue.

- Slow throughput, limiting production capacity.

- Increased labor dependence makes scaling difficult.

- Dust and debris issues, potentially contaminating sensitive components.

Over time, these issues contribute to higher rejection rates and reduced overall yield — factors that can outweigh the perceived cost savings of manual work.

⚡ Advantages of Saw Blade Depaneling Machines

A saw blade depaneling machine offers a fully automated approach, using programmable motion control and precision blades to ensure clean, uniform cuts. The advantages include:

- Precision and Repeatability – Consistent cutting results, even for fine-pitch or dense layouts.

- Reduced Mechanical Stress – The saw blade applies minimal force, preventing component damage.

- High Efficiency – Faster cutting speed and automatic loading/unloading significantly boost productivity.

- Lower Long-Term Cost – While the upfront investment is higher, operational costs (labor, rework, scrap) are much lower.

- Adaptability – Supports various PCB materials, including FR4, CEM-1, and aluminum boards.

In high-volume production environments, these advantages translate directly into better ROI and higher production stability.

💰 Cost Comparison: Manual vs Saw Blade Depaneling

| Cost Factor | Manual Depaneling | Saw Blade Depaneling Machine |

|---|---|---|

| Initial Investment | Low | Medium to High |

| Labor Cost | High (per operator) | Low (one operator for multiple machines) |

| Scrap/Reject Rate | 3–7% | <1% |

| Speed (Boards/Hour) | 100–200 | 600–1200 |

| Maintenance | Minimal | 緩やかな |

| ROI Period | Long (hidden loss) | Short (6–12 months) |

Although manual depaneling may appear cheaper initially, the hidden costs of quality loss and labor inefficiency can quickly surpass the cost of automation.

In contrast, a saw blade depaneling machine delivers consistent results, enabling factories to reduce human error and maintain stable production costs over time.

🏭 Case Study: From Manual to Saw Blade Depaneling

A mid-sized electronics manufacturer producing automotive PCBs relied on manual depaneling for years. Despite experienced operators, the defect rate hovered around 5%, mainly due to stress cracks near components.

After introducing an inline saw blade depaneling machine, the company observed:

- Defect rate reduction: From 5% to under 0.5%

- Throughput increase: 3x higher cutting speed

- Labor cost savings: Two operators replaced by one automated line

- ROI achieved in 9 months

Beyond cost savings, the factory also reported fewer customer complaints and more predictable delivery schedules — benefits that strengthened their competitive edge.

💡 Practical Considerations Before Upgrading

Before switching to a saw blade depaneling machine, consider the following:

- Production Volume: For low-volume production, manual may still be feasible.

- Board Design: Thin or sensitive PCBs benefit most from machine precision.

- Budget and Space: Automated systems require more floor space but deliver higher capacity.

- Operator Training: Ensure basic understanding of setup, maintenance, and safety.

By evaluating these factors, manufacturers can make informed decisions and avoid over- or under-investment.

💬 Industry Discussion: What’s the Right Balance?

While automation brings clear advantages, it’s important to recognize that manual depaneling still has value in prototyping or small-batch production. The key is finding the balance between flexibility and efficiency.

Many factories are now adopting a hybrid approach — using manual depaneling for R&D and pilot runs, and saw blade machines for mass production. This strategy ensures both adaptability and cost control across the production cycle.

What’s your experience? Have you made the switch to automated depaneling, or do you still rely on manual processes? Sharing insights across the industry helps everyone find smarter, more cost-effective solutions.

✅ Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

If you’re considering upgrading your depaneling process or exploring cost-effective automation, contact Seprays Group today.

Our technical team can assess your production needs and recommend the best solution for your factory.

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)