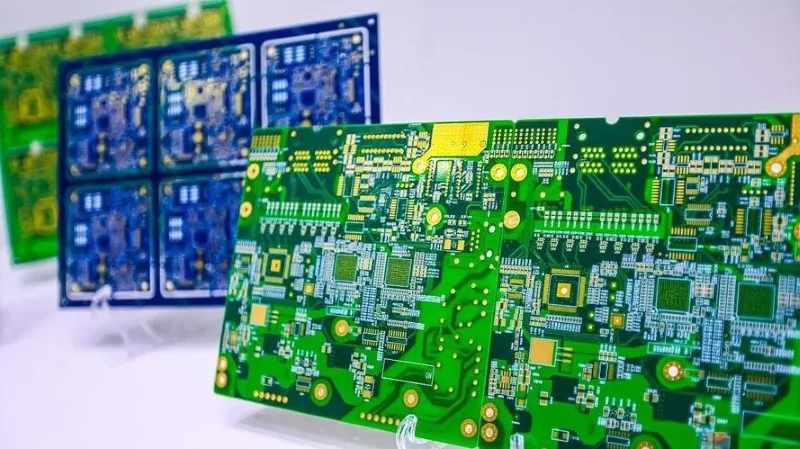

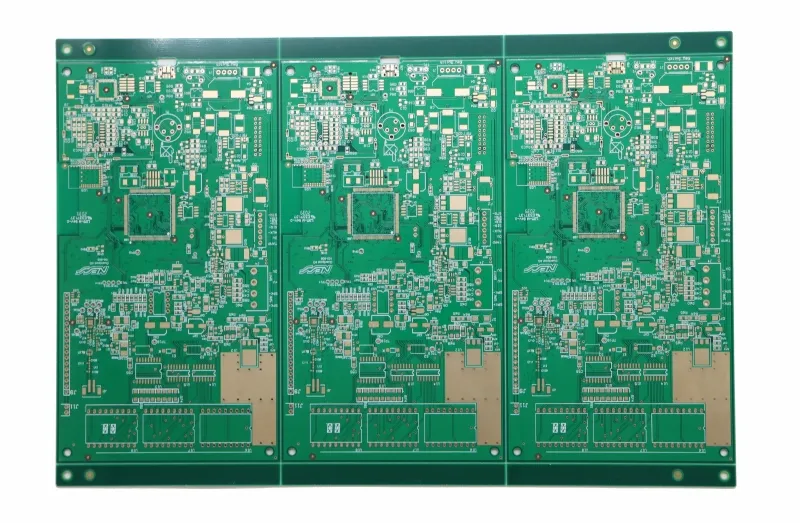

The top 10 PCB Depaneling Machines are no longer judged by speed alone. In 2026, global SMT lines evaluate depaneling equipment through a broader lens: stress control, long-term reliability, traceability readiness, and total cost of ownership. This article summarizes lessons learned from engineers, EMS managers, and process teams who have worked with different depaneling technologies across high-mix and high-volume production.

🧩 Why “Top 10” Is Harder Than It Sounds

Unlike pick-and-place machines, PCB depaneling systems are deeply tied to board design, material thickness, and downstream reliability. What performs well in consumer electronics may fail silently in automotive or medical applications.

Engineers often point out:

- The “best” machine depends more on process fit than brand ranking

- Stress, dust, and micro-cracks don’t always show up at AOI

- Equipment selection mistakes surface months later in field returns

This is why many SMT managers hesitate to rely on simple ranking lists.

⚙️ Core Categories Found in the Top 10 PCB Depaneling Machines

Across 2024–2025 global SMT projects, most machines considered “top tier” fall into three technical categories:

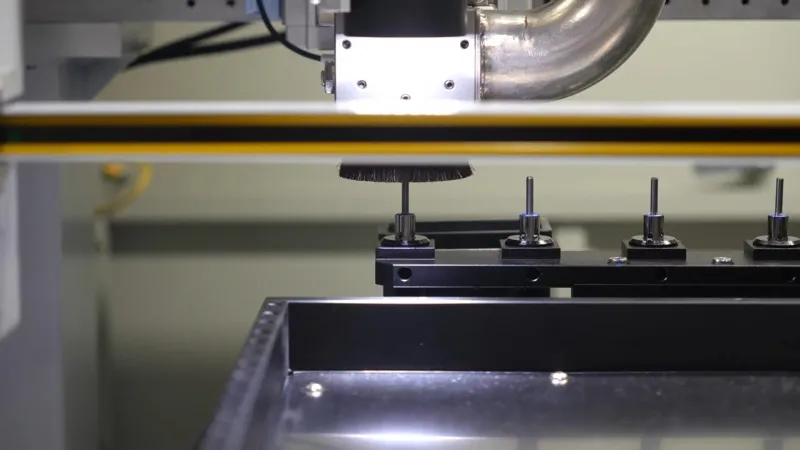

🔧 Router Depaneling Systems

- Widely used for complex outlines and dense layouts

- Lower mechanical stress when parameters are optimized

- Tool wear and dust control become key long-term variables

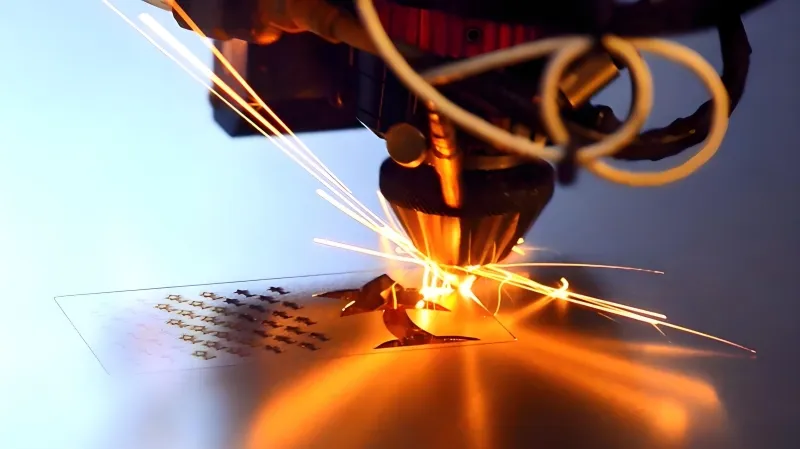

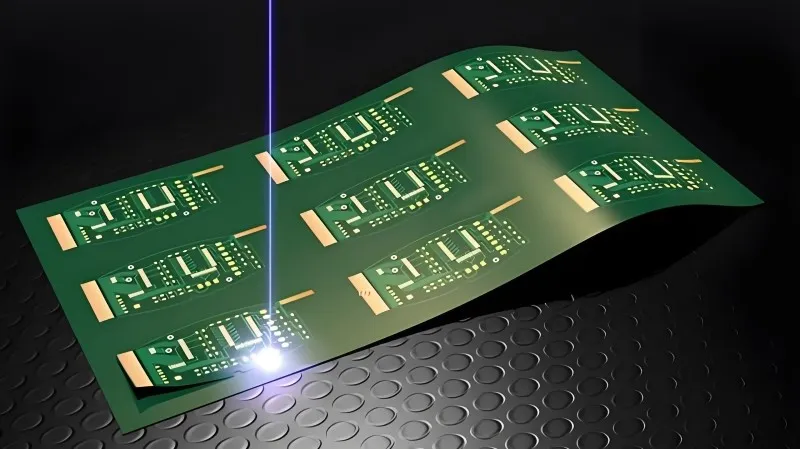

🔦 Laser Depaneling Machines

- Preferred for ultra-thin or high-density PCBs

- No mechanical contact, minimal stress

- Higher upfront cost and material limitations

🪚 V-Cut / Blade Depaneling Solutions

- Cost-effective for high-volume, standardized panels

- Fast cycle times

- Less forgiving for sensitive components near cut lines

Most “Top 10” lists include representatives from all three categories rather than focusing on a single technology.

📉 Common Buyer Mistakes Observed in 2025 Projects

From post-installation reviews, several patterns appear repeatedly:

- Over-prioritizing cycle time over stress distribution

- Ignoring tool life and consumable cost in ROI calculations

- Underestimating dust management requirements

- Selecting machines without considering future traceability needs

One EMS case shared that a lower-cost depaneling system saved money upfront but increased downstream failure analysis costs by over 20% within a year.

💰 Cost Analysis: Looking Beyond the Purchase Price

When evaluating Top 10 PCB Depaneling Machines for 2026, experienced teams model costs across three layers:

- Initial Investment

Machine price, installation, and training - Operational Cost

Tools, maintenance, energy, scrap rate - Quality Risk Cost

Latent defects, warranty exposure, and reputation impact

Machines that appear “expensive” often prove more economical when used in automotive or industrial electronics over a 3–5 year lifecycle.

🧪 Case Insight: High-Density Automotive PCB Line

A European automotive supplier compared three depaneling options on the same product:

- V-Cut showed speed advantages but higher stress near connectors

- The router achieved a better balance with optimized spindle control

- Laser delivered the best quality but exceeded cost targets

Final decision: inline router depaneling with enhanced dust extraction, balancing quality and ROI.

🛠️ How Engineers Recommend Choosing in 2026

Rather than chasing rankings, process engineers suggest asking:

- What stress level can my product tolerate?

- Is this design likely to change in the next 24 months?

- Do I need inline integration and traceability?

- What failures would be hardest to explain to my customer?

The “best” choice is often the one that creates the fewest unknowns.

🧭 Why Choose Seprays Group?

Seprays Group works closely with global SMT lines to match depaneling technology to real production conditions, not just specifications. Our experience spans router, laser, and blade solutions across automotive, industrial, and high-reliability electronics.

Rather than pushing a single answer, we focus on:

- Process-level evaluation

- Stress-aware depaneling strategies

- Long-term equipment stability and serviceability

If you need to discuss your application, panel design, or future production plans, please feel free to contact us. We’re always open to technical exchange and practical discussion.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)