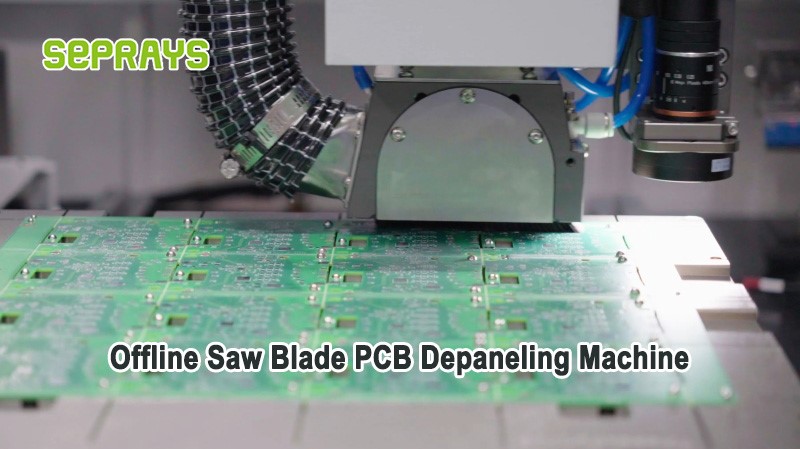

Offline Saw Blade PCB Depaneling Machine Performance Across Different Regions

Offline Saw Blade PCB Depaneling Machine performance varies significantly across regions, and understanding these differences helps manufacturers benchmark efficiency, reduce tooling costs, and improve long-term reliability. In Europe—especially Germany and France—the focus often shifts toward industrial durability, consistent cutting quality, and stable long-term cost control rather than short-term output alone.This article shares practical observations, production challenges, and field experiences gathered from various markets to encourage deeper discussion within the industry. 🏭 H1. Regional Expectations: Efficiency vs. Cutting Quality Manufacturers in Germany often demand highly predictable cutting performance, prioritizing structural durability of the saw blade mechanism and minimization of micro-cracks along V-grooves. French electronics producers lean toward smooth processing of mixed-material […]

How Different Regions Approach PCB Depaneling Efficiency and Cutting Quality

How Different Regions Approach PCB Depaneling Efficiency and Cutting Quality is a topic that global manufacturers continuously compare when improving their SMT processes. As PCB designs become thinner, denser, and more sensitive, depaneling strategies have evolved differently across Asia, Europe, and North America. Many factories now revisit their cutting methods not only to boost efficiency, but also to ensure long-term stability, low stress, and consistent quality. This article shares practical observations from international manufacturers, summarizes common pain points, and analyzes how different regions optimize their depaneling processes. 🔧 H1. Regional Priorities in PCB Depaneling — What Really Drives Decisions? Manufacturers in different regions have distinct priorities shaped by labor structure, […]

What Worldwide Manufacturers Have Learned About Improving Milling Cutter Life

Milling Cutter Life is a topic that every PCB manufacturer—large or small—must take seriously. As factories across Europe, Southeast Asia, and North America continue optimizing PCB routing processes, one lesson repeats itself: longer tool life is not only a cost advantage—it is essential for stable quality, reduced downtime, and predictable production planning. In this article, we summarize what global manufacturers have learned, based on real factory cases, engineering experience, and field feedback from SMT lines. 🔧 H1: Understanding the Real Pain Points Behind Milling Cutter Life Most factories initially approach cutter life as a simple “durability” problem. But German and French manufacturing engineers often emphasize a more holistic view: A […]

How Tooling, Spindle Speed, and Routing Paths Impact PCB Milling Cutting Effect

How Tooling, Spindle Speed, and Routing Paths Impact PCB Milling Cutting Effect is a topic frequently discussed among manufacturing engineers aiming to improve precision while controlling operational cost. Across German and French factories—known for their industrial craftsmanship, durability expectations, and engineering discipline—PCB milling performance is not judged only by cutting quality, but also by the long-term stability of the process. In this article, we share practical insights from real factory experiences, cost analyses, and lessons learned from high-volume SMT lines. 🔧 H1: The Critical Role of Tooling Quality in Milling Performance For many factories, tooling is often treated as a consumable rather than a strategic factor. However, engineers from automotive, […]

Seprays Successfully Concludes Productronica 2025 — Thank You for Joining Us in Munich

Seprays proudly concluded a successful exhibition at Productronica 2025, held from November 18–21 in Munich, Germany. We were honored to welcome visitors from around the world to Hall A3, Booth 144, where we showcased our latest advancements in intelligent PCB depaneling technologies. ⭐ A Great Experience Meeting Global Partners Throughout the four-day event, our team had the pleasure of meeting industry partners, long-term customers, and new friends from Europe, Asia, the Americas, and beyond.Productronica continues to be one of the most influential platforms in the electronics manufacturing industry, and this year’s edition once again demonstrated the strong global demand for high-precision, high-efficiency PCB depaneling solutions. Your active discussions, valuable insights, […]

Saw Blade Depaneling Machine Manufacturer for the U.S. Market — What to Consider

Saw Blade Depaneling Machine is a crucial topic for any SMT engineer or production manager supplying the U.S. electronics manufacturing market. In this article, we explore the key factors that influence machine quality, long-term operation, compliance, maintenance cost, and supplier selection. The goal is not marketing, but to share experience, compare industry standards, and help teams make more confident decisions when upgrading or replacing saw-type V-cut PCB separators. 🔧 Overview: Why the U.S. Market Has Higher Requirements The U.S. electronics manufacturing sector—especially automotive, medical, industrial controls, and aerospace—sets strict expectations for durability, repeatability, and workplace safety. Saw Blade Depaneling Machine buyers frequently emphasize: These expectations shape what manufacturers need to […]

Avoiding Common FPC Punching Errors: Lessons from Southeast Asian SMT Lines

Avoiding Common FPC Punching Errors is becoming a critical topic as Southeast Asian SMT factories continue to scale volume while facing rising quality expectations from European and global customers. With FPC substrates becoming thinner, softer, and more complex, even minor deviations in the punching process can lead to yield loss, dimensional inaccuracies, or damage to fragile copper traces.This article summarizes real issues observed in Vietnam, Malaysia, and Thailand SMT lines and provides engineering-driven guidance in a tone aligned with German and French industrial expectations: precise, durable, and experience-based. 🔧 H1 — Why FPC Punching Is More Challenging Than Rigid PCB Cutting FPC materials behave differently from FR4. They stretch, bend, […]

Laser vs Blade PCB Cutting — Which One Fits Your Factory?

Laser vs Blade PCB Cutting is a common comparison in European factories where reliability, repeatability, and long-term durability matter as much as upfront cost. German and French manufacturers often face pressure to balance high-quality production with restrained investment budgets. This article offers a practical, engineering-focused discussion to help make an informed decision based on real pain points from the shop floor. 🔧 H1 — Understanding the Two Cutting Principles Both laser and blade methods have proven industrial value, but their strengths differ: Factories choosing between them typically prioritize:precision, cut quality, long-term stability, consumable cost, and compatibility with various PCB stack-ups. ⚙️ H2 — Common Pain Points in EU PCB Production […]

Top 5 Affordable PCB Depaneling Machines for Small Factories

🛠️ Overview: practical choices for constrained budgets Top 5 Affordable PCB Depaneling Machines for Small Factories — for many small EMS and prototype shops in Germany and France, the right depaneling machine must balance industrial durability, repeatable accuracy, and low total cost of ownership. This guide highlights five machine types/models (by category), explains where they fit, and shows how small factories can save money without sacrificing quality. ⚙️ 1 — Compact Router Systems (Best all-rounder) Compact router depaneling machines use a small high-speed spindle and CNC motion to cut panels with low stress. They are: 🔩 2 — Bench-top Saw Blade Units (Lowest entry cost for rigid boards) Simple, benchtop […]

How to Save Cost in PCB Cutting without Losing Accuracy

How to Save Cost in PCB Cutting is becoming a key discussion topic in European electronics manufacturing. German and French automotive, industrial control, and medical device producers frequently share the same concern: “We need lower production cost, but we cannot afford dimensional deviation, stress cracks, or burrs caused during PCB depaneling.” Precision requirements keep rising, while budgets are carefully evaluated under long-term operational cost rather than just machine purchase price. This article explores practical and experience-based approaches to balance cost and precision in PCB cutting. 🏭 Why PCB Cutting Accuracy Matters in European Manufacturing High-end PCBs used in robotics, railway electronics, charging systems, aerospace, and power management are subject to […]

.png)