Milling cutter PCB depaneling machine accuracy is a recurring discussion point among process engineers working with high-value and high-density PCBAs. ±0.05 mm is often quoted in specifications—but can it be achieved consistently in real production? The short answer is yes, under defined conditions. The longer answer depends on process control, mechanical design, and expectations around repeatability versus peak performance.

This article shares field-proven insights from EMS and OEM production lines, focusing on industrial quality, durability, and realistic cost–performance trade-offs.

🧭 What Does ±0.05 mm Accuracy Actually Mean in Production?

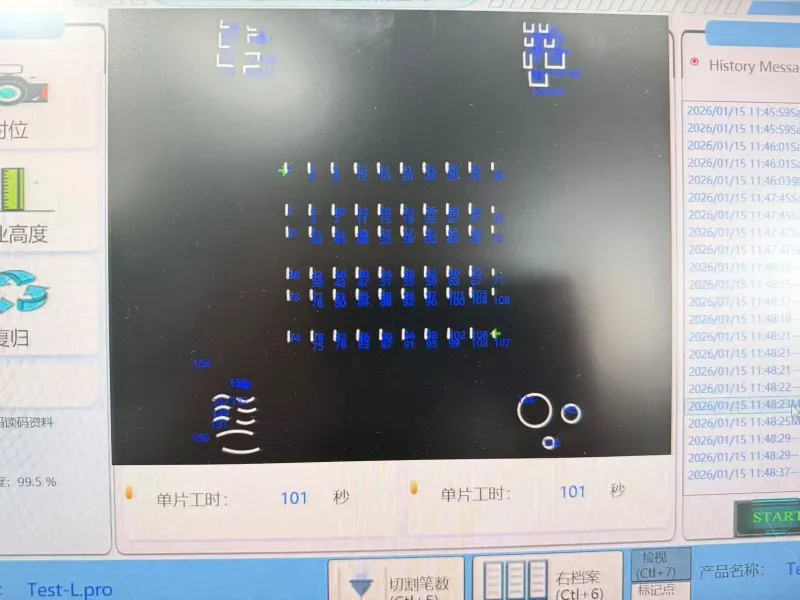

In practice, cutting accuracy refers to the deviation between the programmed tool path and the final board edge. Engineers often discover that:

- One-time measurement ≠ of long-term stability

- Edge accuracy varies across panel locations

- Thermal drift and tool wear matter more than nominal specs

For most SMT lines, ±0.05 mm must be evaluated as process capability, not just machine resolution.

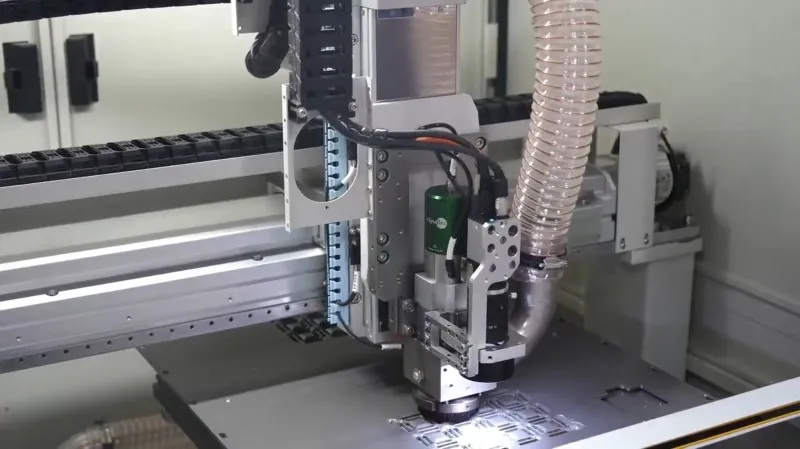

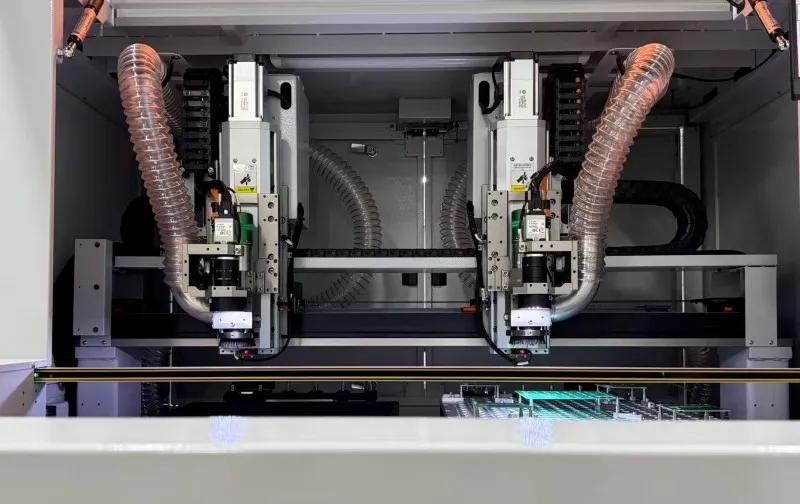

⚙️ Key Mechanical Factors That Enable High Accuracy

Achieving tight tolerances is less about marketing claims and more about mechanical fundamentals:

- Rigid gantry and spindle structure to minimize deflection

- Low runout spindle bearings are suitable for continuous operation

- Stable Z-axis depth control across uneven panels

Production audits show that machines with stronger mechanical damping maintain accuracy longer during extended shifts.

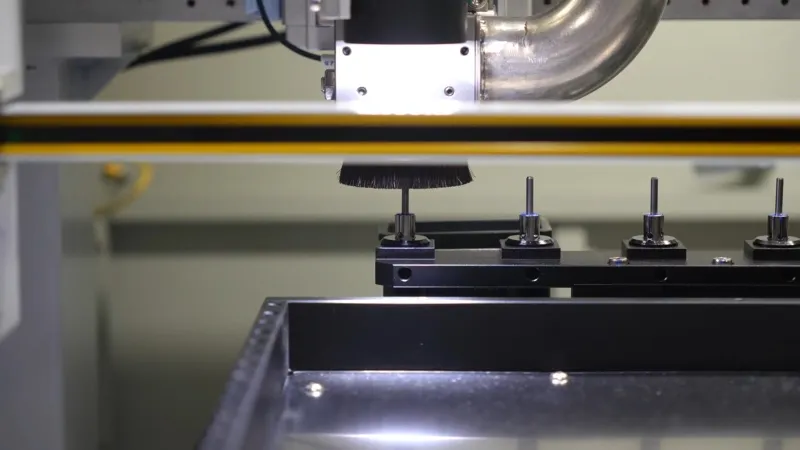

🪚 Tooling and Process Control: The Hidden Variables

Even with a capable system, results degrade quickly without discipline:

- Worn cutters increase lateral force and edge variance

- Inconsistent feed rates amplify vibration at corners

- Poor dust extraction causes heat buildup and material smear

Several lines reached ±0.05 mm only after switching from time-based to cut-length-based tool replacement strategies.

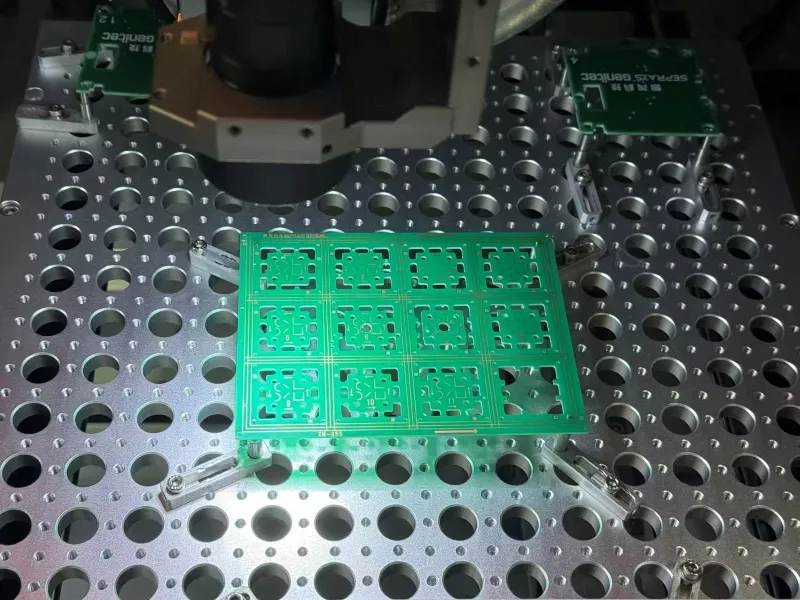

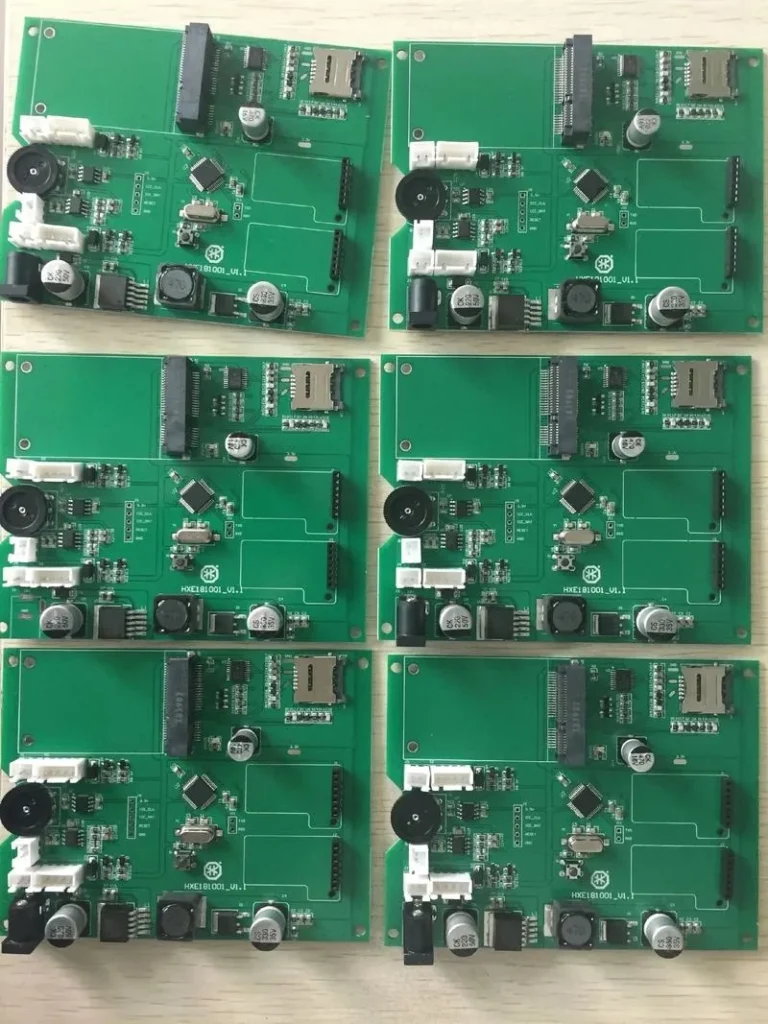

🧩 Panel Support and Fixturing Matter More Than Expected

High-accuracy routing requires minimizing board movement. Field data highlights:

- Full-area vacuum support reduces local flex

- Poor support can double the measured edge deviation

- Dense PCBAs amplify small mechanical errors

This is why many failures attributed to machine accuracy were ultimately traced back to fixture design.

📉 Cost Perspective: Precision vs. Practical Yield

While chasing extreme accuracy increases upfront investment, the long-term economics are often favorable:

- Fewer cracked-edge components

- Lower scrap during ICT and functional testing

- Reduced manual inspection and rework

One industrial electronics customer reported a 20% yield improvement after optimizing routing accuracy—without changing board design.

🏭 Case Insight: Automotive Control Module

An automotive supplier required ±0.05 mm edge tolerance to protect connectors near the board outline. After tuning spindle speed, routing sequence, and fixture flatness, the milling cutter PCB depaneling machine met the requirement consistently across three shifts, validated over six months of SPC data.

🛠️ Practical Guidelines for Engineers

- Validate accuracy under real production conditions

- Treat tooling and fixtures as part of the accuracy system

- Monitor long-term drift, not just initial measurements

- Balance tolerance goals with cost and throughput

In most cases, ±0.05 mm is achievable—but only with a system-level mindset.

💬 Why Choose Seprays Group?

Seprays Group focuses on industrial-grade PCB depaneling solutions designed for long-term accuracy, mechanical durability, and stable process capability. Our routing systems are developed to support tight tolerances while maintaining reliability across high-volume production.

If you would like to evaluate whether ±0.05 mm accuracy is realistic for your application, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)