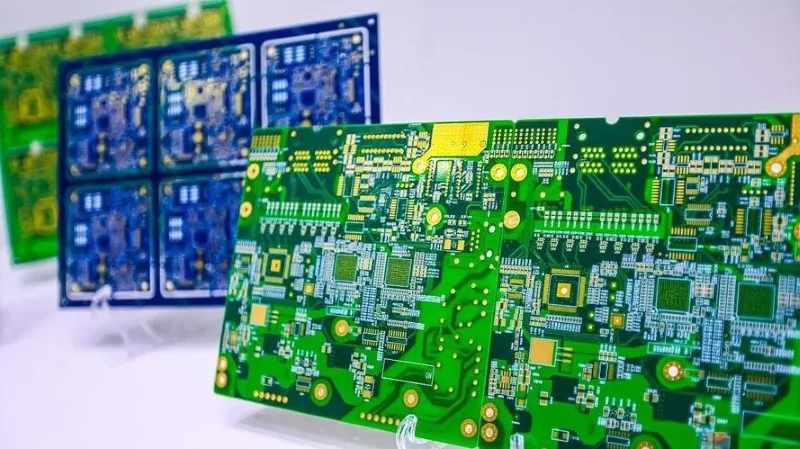

How to Reduce Mechanical Stress in PCB Depaneling has become a critical discussion in modern SMT production. As PCBs become thinner, denser, and populated with sensitive components, uncontrolled mechanical stress during separation can lead to micro-cracks, solder joint fatigue, and reduced reliability over time. This article shares insights from global SMT lines on minimizing stress, balancing cost, and improving yield.

⚙️ Understanding Mechanical Stress in Depaneling

Mechanical stress arises whenever a PCB is separated from its panel using routers, V-cut, or blade depaneling systems. Common stress points include:

- Near edges of dense component placement

- Along score lines in V-cut panels

- Around vias and rigid-flex transition zones

Engineers emphasize that stress is not always visible at AOI but can manifest later during thermal cycling or vibration tests, especially in automotive and industrial electronics.

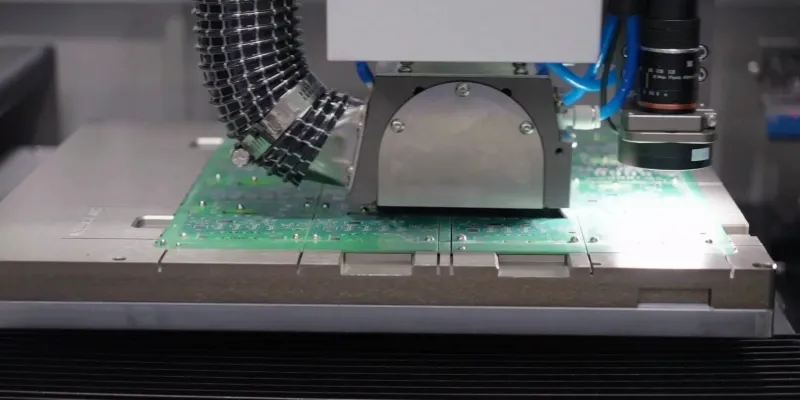

🧩 Router Depaneling: Precision and Force Management

Router depaneling is widely used due to its flexibility and control. Best practices to reduce mechanical stress include:

- Optimizing spindle speed to match PCB thickness

- Using sharp, high-quality bits to reduce cutting force

- Implementing vacuum or fixture support to prevent panel flex

- Regular maintenance to avoid vibration or spindle play

Case insight: A European automotive supplier reduced micro-crack incidents by 30% after recalibrating router feeds and installing anti-vibration supports.

🪚 V-Cut Depaneling: Controlled Break Force

V-cut depaneling is cost-effective for high-volume production but can concentrate stress at score lines. Tips for stress reduction:

- Ensure precise scoring depth and uniform blade sharpness

- Control separation speed and tool alignment

- Maintain consistent panel thickness across production batches

- Design PCBs with adequate edge spacing to reduce component stress

Several EMS lines report that careful control of these parameters reduced post-depaneling solder defects significantly.

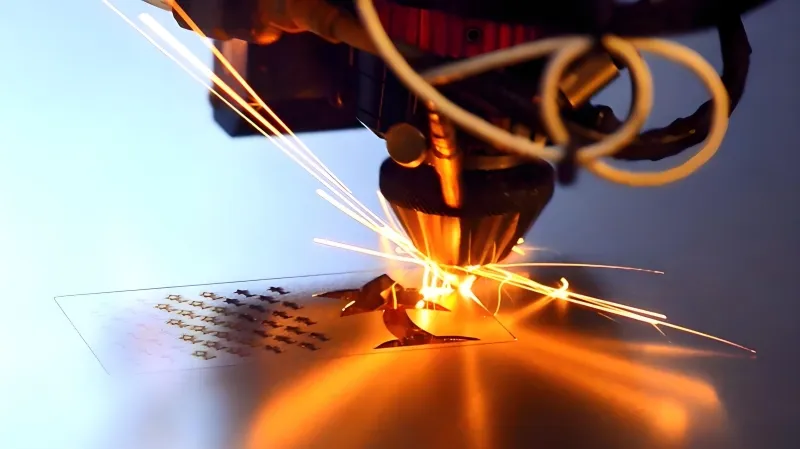

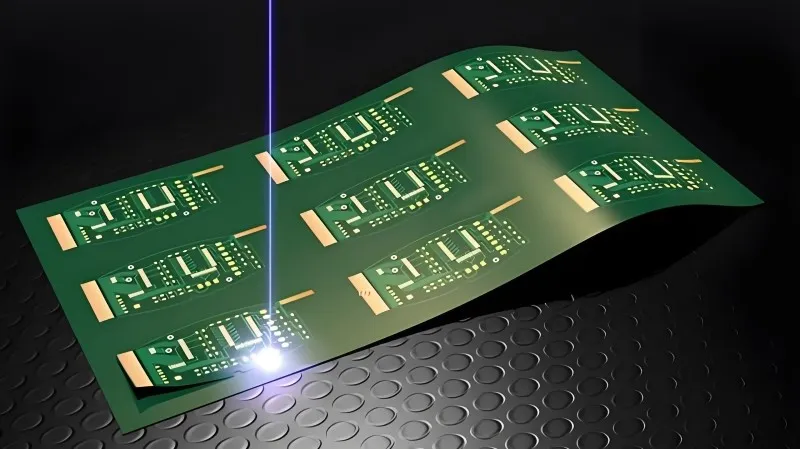

🔥 Laser Depaneling: Minimizing Physical Contact

Laser depaneling virtually eliminates mechanical contact, providing the lowest stress method for sensitive or thin boards. Practical considerations include:

- Optimizing laser power and focus for minimal thermal impact

- Ensuring proper ventilation to prevent debris deposition

- Integrating inline inspection to detect surface micro-damage

While upfront cost is higher, stress reduction and repeatability often justify investment in high-value applications.

📉 Cost and Yield Implications

Reducing mechanical stress directly impacts cost and yield. Hidden benefits include:

- Fewer field failures and warranty claims

- Reduced rework and inspection time

- Extended tool life and lower maintenance costs

Engineers advise evaluating depaneling solutions based on the total cost of ownership, rather than just the equipment price.

🏭 Real-World Case Example

A medical electronics EMS line observed repeated failures in flex-rigid connectors. After switching to optimized laser depaneling for those specific panels, defect rates dropped by over 40%. Router machines remained in use for less sensitive boards, demonstrating a hybrid approach tailored to product requirements.

🛠️ Practical Tips for SMT Lines

- Assess PCB design for stress-sensitive areas before panel separation

- Match depaneling technology to product characteristics

- Monitor tool wear, spindle vibration, and scoring depth regularly

- Document and validate stress reduction measures for traceability

These steps help engineers align depaneling with both quality standards and operational efficiency.

💬 Why Choose Seprays Group?

Seprays Group specializes in depaneling solutions designed for industrial-grade quality, durability, and stress-aware performance. We support engineers in selecting, optimizing, and maintaining router, V-cut, and laser depaneling systems for automotive, medical, and industrial electronics.

If you would like to discuss stress reduction techniques or tailor solutions for your SMT production line, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)