新着情報

Safety issues to watch in laser PCB depaneling

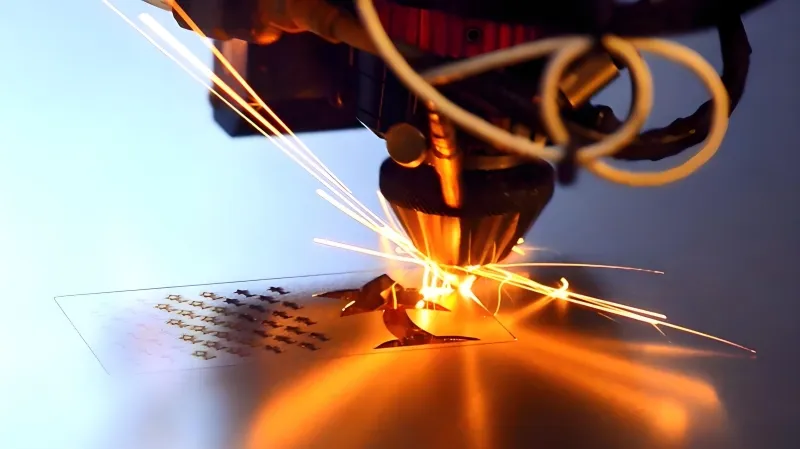

Laser PCB depaneling is increasingly used for low-stress, high-precision applications. However, choosing laser technology does not automatically mean “risk-free.” Based on real production experience, most problems come not from the laser itself, but from overlooked safety details in setup, operation, and process design. This checklist-style article highlights where teams often get it wrong—and how to avoid those pitfalls. ⚠️ Why Safety Is Often Underestimated in Laser Depaneling Laser depaneling is a non-contact process, so it feels safer than routing or sawing. No blades, no vibration, no mechanical force.That perception can lead to relaxed standards, especially during early deployment. Common pain points engineers report include: Safety in laser depaneling is not only about people—it directly affects product quality and cost. 👀 Pitfall 1 – Ignoring Laser Radiation Control The most basic risk is also the most critical. Even Class 1 systems require disciplined enclosure design. Reflected or scattered laser energy may not injure operators immediately, but it can degrade sensors or cameras over time. Avoidance tip:Always verify enclosure integrity and interlock logic during commissioning—not just during factory acceptance. 🌫️ Pitfall 2 – Underestimating Fume and Particle Hazards Laser depaneling vaporizes material instead of cutting it mechanically. This creates: Without proper extraction,

Which PCB depaneling method causes the least stress?

This question comes up whenever PCBA reliability, fine-pitch components, or thin substrates are involved. The short, experience-based answer is: laser depaneling introduces the lowest mechanical stress, but it is not always the default choice. Below is a clear comparison to help engineers make a practical decision. 🧠 Why Depaneling Stress Matters More Than You Think Mechanical stress during depaneling is a hidden risk. It may not show up during visual inspection, but it often leads to: As component density increases and boards become thinner, depaneling stress becomes a design constraint, not a secondary process issue. ⚙️ Common PCB Depaneling Methods at a Glance In practice, manufacturers mainly choose between four methods: Each method removes material differently—and that directly affects stress levels. 📊 Stress Comparison by Depaneling Method Below is a simplified comparison based on field experience and production feedback. Method Mechanical Stress Edge Quality Design Flexibility Hidden Risk V-cut High Medium Low Board bending Saw blade Medium Medium Medium Vibration Routing Low–Medium Good Good Tool pressure Laser Near zero Excellent Excellent Minimal Key takeaway: Laser depaneling consistently produces the lowest stress because it is a non-contact process. 🔍 Why Laser Depaneling Causes the Least Stress Unlike mechanical methods, laser depaneling

When should I choose router depaneling over V-cut?

The choice between router depaneling and V-cut largely depends on the design and requirements of your PCBA. While both are popular methods for separating boards, each method offers distinct advantages depending on factors like board thickness, component sensitivity, and precision needs. This article will explore when router depaneling is the better choice over V-cut, with a focus on practical considerations and real-world examples. ⚙️ What are the differences between router depaneling and V-cut? Before we discuss when router depaneling is preferred, let’s compare both methods briefly. V-Cut Depaneling: Router Depaneling: 🔍 When should you choose router depaneling over V-cut? Router depaneling is the preferred choice in the following situations: 1. Thicker PCBs or Rigid-Flex Designs For thicker boards (greater than 1mm) or rigid-flex PCBs, router depaneling provides the cutting power needed to maintain clean, stress-free separation. V-cuts are usually too shallow for thicker boards and may lead to breakage or incomplete separation, especially when dealing with multiple layers. Example:A medical device manufacturer needed to process rigid-flex boards with multiple layers of sensitive components. Router depaneling provided precise cuts without damaging internal layers or causing delamination. V-cut wasn’t an option because it didn’t offer enough depth to handle these complex materials.

When should you choose laser depaneling over routing?

This is a common question for PCB and PCBA engineers facing tighter tolerances, denser layouts, and rising cost pressure. The short answer: choose laser depaneling when mechanical stress, edge quality, or design freedom becomes a limiting factor. Below is a practical, experience-based breakdown to help you decide. 🔍 Understanding the Core Difference Routing (milling) relies on physical contact between a rotating tool and the PCB. Laser depaneling, by contrast, uses a focused laser beam to separate boards without contact.The real difference shows up in stress, precision, and design flexibility—not just cutting speed. ⚠️ Key Pain Points with Traditional Routing Engineers often start questioning routing when they encounter these issues: Routing works well for many standard FR-4 panels, but as boards get thinner and layouts denser, its limits become visible. 🎯 When Laser Depaneling Makes More Sense You should seriously consider laser depaneling over routing if your project involves: In these scenarios, even well-optimized routing can introduce risks that are hard to eliminate. 💰 Cost Analysis – Looking Beyond the Machine At first glance, laser systems appear more expensive. But the total cost of ownership tells a different story: For low- to mid-volume, high-mix production, laser depaneling often balances out—or even

Is laser depaneling suitable for flexible PCBs?

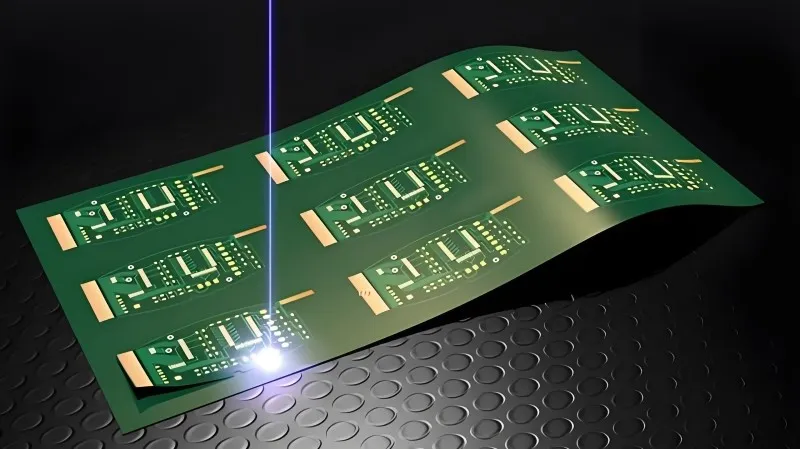

Laser depaneling for flexible PCBs is increasingly popular in high-density electronics. Flexible PCBs are thin, stress-sensitive, and often densely populated. Mechanical methods like routing or V-cut can introduce micro-cracks, fiber pull-out, or board warping. Laser depaneling removes these risks, making it highly suitable when applied correctly. This article shares practical insights, production challenges, and cost considerations, with examples from EMS and OEM lines, including selective use of Seprays-supported laser depaneling. 🔍 Why Flexible PCBs Need Special Care Flexible PCBs bend and twist easily. Even minor mechanical stress during depaneling can lead to: For high-value products—automotive sensors, wearables, medical electronics—avoiding stress is critical. Laser depaneling eliminates mechanical contact, directly addressing these pain points. ⚙️ How Laser Depaneling Works on Flexible PCBs Laser depaneling uses a focused light beam to ablate PCB material without physical contact. Key effects for flex PCBs: Compared with routing, laser depaneling spreads cutting energy over time rather than applying instantaneous stress. ✨ Advantages of Laser Depaneling for Flexible PCBs Field experience shows these benefits: Flexible PCBs benefit more than rigid boards, especially in dense layouts or when components are close to the edge. 💡 Production Insights and Pain Points In real EMS lines: Introducing Seprays-supported laser depaneling,

What PCB materials are suitable for laser depaneling?

PCB materials suitable for laser depaneling are not unlimited, and laser is not always the right answer. In real SMT production, laser depaneling performs extremely well for specific materials and use cases, while being less effective or inefficient for others. So instead of asking “Can laser cut this PCB?”, engineers usually ask a more practical question:“Is laser depaneling the most stable and cost-effective option for this material?” 🔍 The Short Answer First Laser depaneling is best suited for PCB materials that are: If your PCB falls into that category, a laser often solves problems that routing or V-cut cannot. ⚙️ PCB Materials That Work Well with Laser Depaneling From real production experience, these materials consistently perform well: 🟢 FPC and Rigid-Flex PCBs Laser depaneling is often the default choice here. 🟢 Thin FR4 (Standard & High-Tg) Most issues only appear when boards become thick or contain a lot of copper. 🟢 BT Resin and High-Precision Substrates These materials are often chosen because laser depaneling is available. ⚠️ Materials That Need Careful Evaluation Laser depaneling is not ideal for everything: Laser can still work—but only after trials and cost checks. In some cases, routing is simply more practical. 💡 Why Engineers

.png)