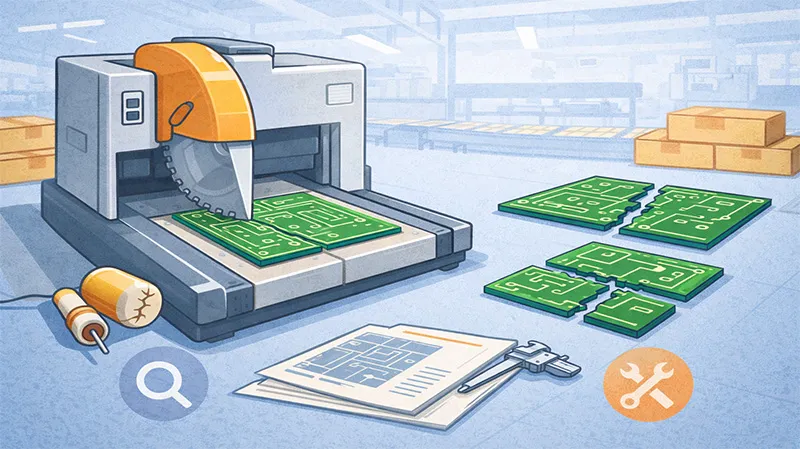

PCB V-Cut Depaneling Machine usage remains widespread in high-volume SMT production, particularly where board designs are standardized, and cost efficiency is critical. Despite the rise of routing and laser solutions, V-cut depaneling continues to play an important role in consumer electronics, power modules, and industrial products. This article shares practical insights from real SMT production lines rather than promotional comparisons.

🧱 Why V-Cut Still Matters in Mass Production

In high-volume environments, simplicity and predictability are often valued over flexibility. Engineers working with V-cut depaneling emphasize that when PCB layout allows sufficient edge clearance, the process can be highly efficient.

Key advantages frequently mentioned:

- Fast separation for large batch sizes

- Low cycle time per panel

- Minimal programming complexity

- Lower initial equipment investment

For stable product designs with long production life cycles, these benefits remain attractive.

⚠️ Stress Behavior — The Primary Engineering Concern

Mechanical stress is the most discussed limitation of V-cut depaneling. In practice, the separation force applied along the groove can affect solder joints and ceramic components.

Common pain points reported:

- Cracked MLCCs near the score line

- Edge deformation on thin PCBs

- Increased failures during thermal cycling tests

As component density increases, controlling break force becomes essential. Many SMT teams adjust scoring depth, blade angle, and separation speed to reduce stress concentration.

⚙️ Machine Durability in 24/7 Production

In high-output factories, machines operate continuously. Engineers often evaluate V-cut equipment based on durability rather than peak throughput.

Observed durability factors include:

- Blade material and wear resistance

- Frame rigidity to prevent misalignment

- Consistency of scoring depth over time

Poor blade condition is one of the most common root causes of quality variation in long production runs.

📉 Cost Analysis — Efficiency vs. Hidden Losses

While V-cut systems are generally cost-effective, experienced production managers caution against evaluating cost only at the purchase stage.

Hidden costs identified in production:

- Scrap from stress-related defects discovered later

- Additional inspection steps near cut edges

- Blade replacement and downtime

- Yield loss during reliability testing

Several factories reported that modest investment in better blade quality and preventive maintenance significantly reduced total cost.

🏭 Case Observations from High-Volume SMT Lines

- Consumer electronics: V-cut remains dominant where board design is optimized for scoring

- Power electronics: Used selectively for rigid boards with low edge sensitivity

- Industrial controls: Applied cautiously, often with conservative separation parameters

Across cases, success depends more on design discipline and process control than machine speed.

🧩 Best Practices Shared by Engineers

From production discussions, several best practices emerge:

- Maintain consistent score depth across panels

- Keep sensitive components away from V-grooves

- Monitor blade wear proactively

- Control the separation speed to limit the shock

- Review the depaneling impact during the PCB design stage

These practices help sustain yield in long-term mass production.

Why Choose Seprays Group?

Seprays Group provides V-cut depaneling solutions designed for industrial durability, consistent scoring accuracy, and stable performance in high-volume SMT environments. Our systems focus on long-term reliability and practical process control rather than short-term speed.

If you would like to discuss V-cut depaneling suitability for your PCB designs, please contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)