説明

| モデル | GAM320AL |

|---|---|

| 有効切断サイズ | 450*500mm |

| 切削機能 | Tweening to straight line, L Shape, U Shape, Circle, and Arc |

| 工程表" | デュアルテーブル |

| 繰り返し精度 | ±0.01mm |

| 切断精度 | ±0.05mm |

| 最大移動速度 | XY: 1000mm/sec, Z: 600mm/sec |

| Max’s moving trip | X: 1010mm, Y: 570mm, Z: 90mm |

| 主軸回転速度 | MAX:60000rpm(調整可能) |

| 切削速度 | 1-100mm/s(調整可) |

| 操作システム | Windows10 |

| The program teaching method | 直感的な教育によるCCDカラー画像入力 |

| プログラムのバックアップ | USBデータ転送 |

| 制御方法 | 精密多軸制御システム |

| XYZ軸駆動モード | ACサーボモーター |

| サイズのミリングビット | 0.8-3.0mm |

| 電圧/電源 | AC220V50/60Hz2.2KW単相 |

| 空気圧の圧力の要件 | 0.6MPa75L/min |

| 重量(W*D*H) | 1445*1670*1550mm |

| 重量 | 510KG |

| 集塵機 | TS200L |

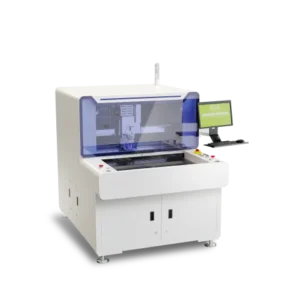

の GAM320AL PCB Router is built for precision, flexibility, and productivity. Engineers designed the system to handle diverse PCB shapes and equipped it with a high-speed CCD vision alignment system to ensure accurate positioning and minimal cutting error.

This advanced router uses a precision spindle to reduce stress during the milling process, protecting sensitive components and improving overall board quality. The GAM320AL PCB Router also features dual worktables, allowing simultaneous loading and routing or merging into a single platform for larger boards—cutting down idle time and increasing throughput.

With customizable options like dual spindles, upper or lower dust collectors, broken tool detection, MES integration, and more, this machine adapts to your production needs.

🛠️ Trusted by Fortune 500 manufacturers worldwide.

製品の特徴

Operation Screen

- Simple settings for panel separation and milling cutter/fixture parameters.

- Processing efficiency and milling cutter usage data are clearly displayed.

- A history window facilitates operation log review.

- Equipped with milling cutter life management, maintenance alerts, and spindle speed settings.

CCD vision automatic calibration system

- Equipped with a high-speed CCD vision automatic calibration system.

- Cutting path simulation assists programming, ensuring accurate cutting paths.

- Full-sheet scanning and offline programming improve path editing efficiency.

Offline programming and full-sheet scanning

- Cutting programs can be edited offline and directly imported into the machine, improving utilization.

- Simpler, more user-friendly, automatic cutting path recognition.

- Scan and edit the entire PCB board to quickly modify the cutting path, improving programming efficiency.

- Selectable cutting line colors for easy identification of different PCB colors.

High-speed cutting spindle

- Imported high-speed, high-precision spindle.

- Low cutting stress, smooth board edges, and high precision.

- High-precision spindle speed of 80,000 rpm.

Maintenance reminder

- Settable maintenance time.

- Dust filter bag cleaning time.

- Timed reminder for operator maintenance.

Quick line change

- Recall existing programs to avoid fixture errors, enabling quick program recall and line change.

Application Cases

.png)

レビュー

レビューはまだありません。