説明

| モデル | ZM30-V |

|---|---|

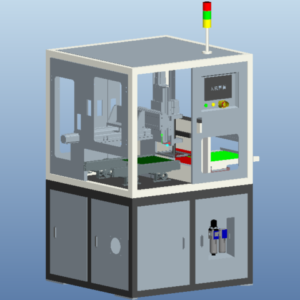

| 勤務地区(基板加工サイズmin-max) | X:300mm,Y:350mm,Z:0-80mm(Min50*50mm、Max300*300MM) |

| 装置サイズ | L850mm*W850mm*H1520mm |

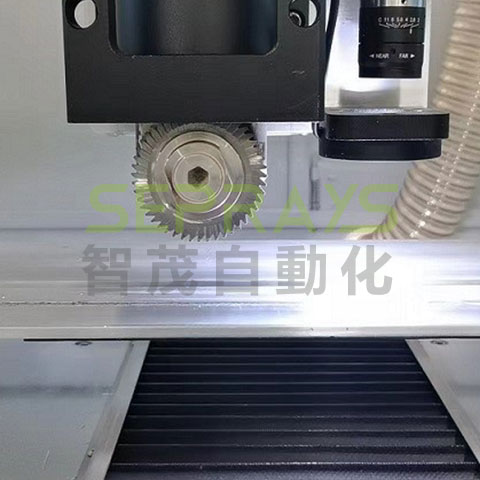

| 鋸刃回転速度 | リミット8000rpm(オプション) |

| X、Y、Z These driving speeds | X、Y軸速度5-500mm/s、Z軸速度5-80mm/s X、Y、Z軸最小移動距離は0.01mm |

| Cutting the PCB thickness range | 0.2-3mm stroubleshooters are only 0.2mm) |

| 切断精度の能力 | ±0.05mm力のカットは直線、円弧、L型、U型、スタンプ穴モデル、Vスロットモデル |

| 機械力(集塵機含む) | 5000W |

| ツールモードの変更 | マニュアルツールの変更が必要なツールレンチへ変更) |

| テーブル数量、機能 | SingleTable |

| スピンドル冷却システム | 空気冷却方法 |

| 集塵機電力モード | 3.5kw380V三相モータを、外部の上下集塵装置(オプション) |

| 空気圧 | 上記0.45Mpa |

| 労働力供給 | 220V,50HZ(集塵機:380V,50HZ) |

| 安全装置 | adopting a safety guard door or sensor |

| モデルモード | オフラインモデルでは、マニュアル入出庫 |

| 備品 | Universal fixtures are available |

| 自動故障検出およびメンテナンスモード | The system has a self-diagnostic function, real-time error message display, can intuitively query the status of the device’s various IO ports, and is easy to troubleshoot |

| 技術サポートやトレーニング | To provide equipment operation, programming, hardware maintenance, and maintenance training services, as well as program permanent free upgrades. (Required) |

| 基板厚み | 0.3-3.5mm |

| ビジョンシステム | CCDビジョン位置決め補正システム |

| 重量 | 約600kg |

| Adjustable height of the foot | 50~70mm |

| 動作範囲保護 | adopting the six-faced door blind protection method |

| ドアインターロック保護センサー | Safety door microswitch sensor |

| 非常停止ボタン | あり |

| 丸ナイフ&フライスナイフ法 | saw tooth thickness 0.2mm~0.3mm (effectively improves cutting accuracy) (optional) |

Product Features

の ZM30-V depaneling machine by SEPRAYS is a high-performance, space-saving solution engineered for efficient and precise PCB depaneling in fast-paced manufacturing environments. Engineers built it to handle multi-connected PCBs with speed and accuracy, making it ideal for consumer electronics, home appliances, and automotive electronics.

Featuring a single-table surface for uninterrupted operation, the machine boosts throughput while ensuring operator safety through its integrated safety grating. The ZM30-V depaneling machine uses advanced vision technology for automatic image mark recognition and alignment. Operators can easily set and monitor track positions, production statistics, and more through a user-friendly interface.

Its powerful negative-pressure dust removal system includes secondary filtration and anti-static functionality, solving dust-related challenges and keeping the environment clean.

.png)

レビュー

レビューはまだありません。