This is a common question for PCB and PCBA engineers facing tighter tolerances, denser layouts, and rising cost pressure. The short answer: choose laser depaneling when mechanical stress, edge quality, or design freedom becomes a limiting factor. Below is a practical, experience-based breakdown to help you decide.

🔍 Understanding the Core Difference

Routing (milling) relies on physical contact between a rotating tool and the PCB. Laser depaneling, by contrast, uses a focused laser beam to separate boards without contact.

The real difference shows up in stress, precision, and design flexibility—not just cutting speed.

⚠️ Key Pain Points with Traditional Routing

Engineers often start questioning routing when they encounter these issues:

- Micro-cracks or solder joint failures after depaneling

- Component keep-out zones are becoming larger due to the tool diameter

- Frequent tool wear, replacement, and downtime

- Noise, dust, and vibration are affecting the inline processes

Routing works well for many standard FR-4 panels, but as boards get thinner and layouts denser, its limits become visible.

🎯 When Laser Depaneling Makes More Sense

You should seriously consider laser depaneling over routing if your project involves:

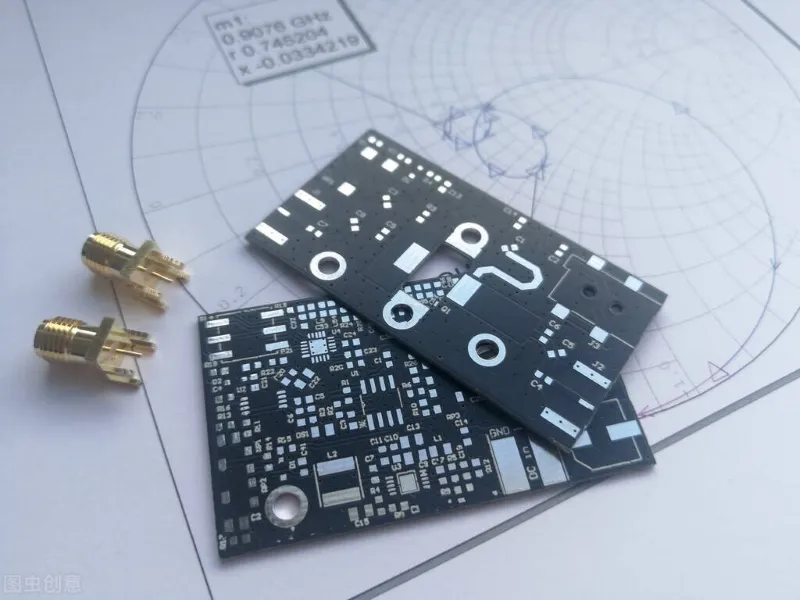

- High-density PCBA with components close to the board edge

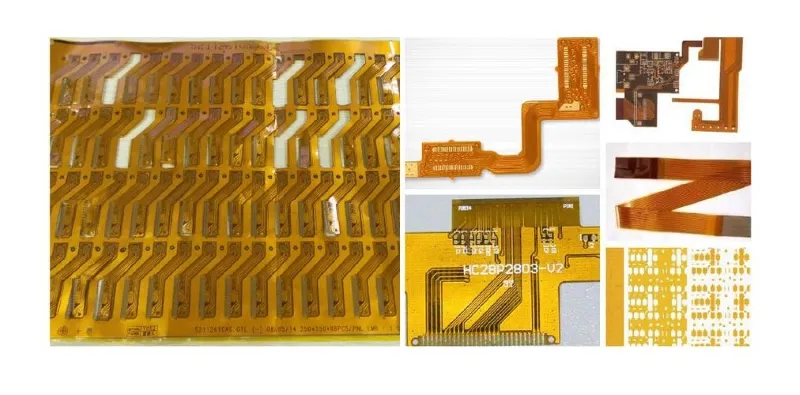

- Flexible, rigid-flex, or ultra-thin substrates

- Irregular outlines or non-linear cutting paths

- Strict stress control requirements, such as automotive or medical electronics

In these scenarios, even well-optimized routing can introduce risks that are hard to eliminate.

💰 Cost Analysis – Looking Beyond the Machine

At first glance, laser systems appear more expensive. But the total cost of ownership tells a different story:

- No cutting tools, blades, or molds to replace

- Reduced scrap from edge damage or micro-cracks

- Higher material utilization due to ultra-narrow kerf

- Less maintenance-related downtime

For low- to mid-volume, high-mix production, laser depaneling often balances out—or even lowers—overall costs over time.

🧪 Real-World Case Insight

A customer producing automotive sensor modules faced recurring post-assembly failures traced back to depaneling stress. Routing met throughput needs but caused invisible mechanical strain.

After testing a Seprays laser depaneling system, they achieved:

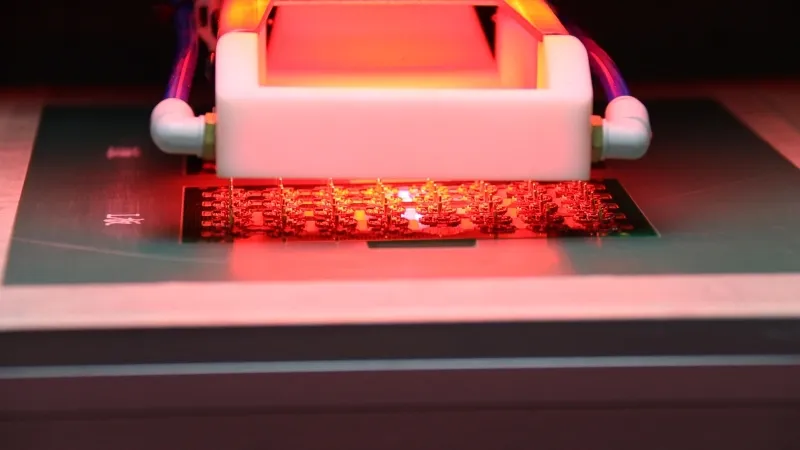

- Clean edges with no mechanical stress

- Stable yields across thin and rigid-flex panels

- Improved panel utilization thanks to finer cutting paths

The switch didn’t replace routing everywhere—but it solved the critical bottleneck where reliability mattered most.

🛠️ Practical Selection Guidelines

Laser depaneling is not a universal replacement. A balanced approach works best:

- Use routing for thick, simple FR-4 panels and high-volume cost-driven lines

- Use laser depaneling for precision-critical, fragile, or complex designs

The question isn’t routing or laser—it’s where each method performs best.

⚡ Seprays Laser Depaneling Advantages

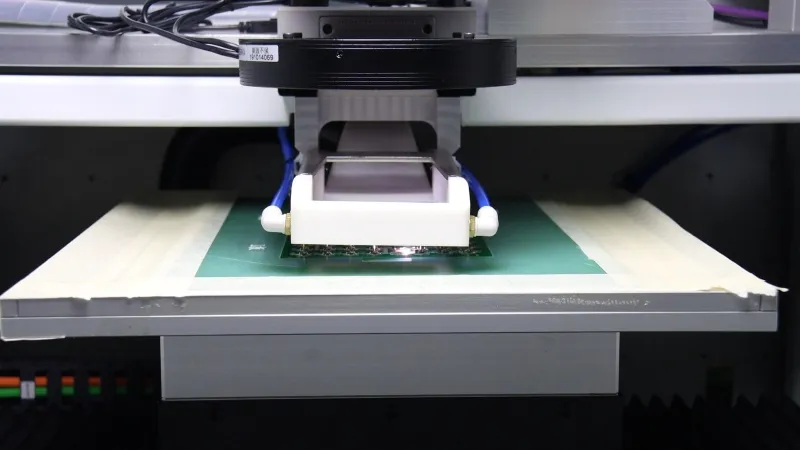

Seprays focuses on precision-driven applications where consistency matters:

- Ultra-high precision (<2 μm)

- No mechanical stress or vibration

- Extremely narrow kerf (<25 μm), improving material utilization

- Free-form cutting without design constraints

- No consumables like blades or molds

- Clean, residue-free cuts

- Fast and automation-friendly for inline production

These features directly address the pain points that push engineers away from routing.

⭐ Why Choose Seprays Group?

Seprays Group combines depaneling process knowledge with application-driven laser solutions. We focus on helping manufacturers choose the right method—not just selling machines.

If you’re evaluating whether laser depaneling is the right fit for your boards, お問い合わせ for a technical discussion or sample test.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)