When to use a down-cutting PCB separator is a common question for engineers and manufacturers. Down-cutting PCB separators are specialized machines designed to safely and efficiently separate printed circuit boards without damaging components. If your project involves small-batch or high-mix production, understanding the right applications is critical.

⚡ Ideal for High-Component PCBs

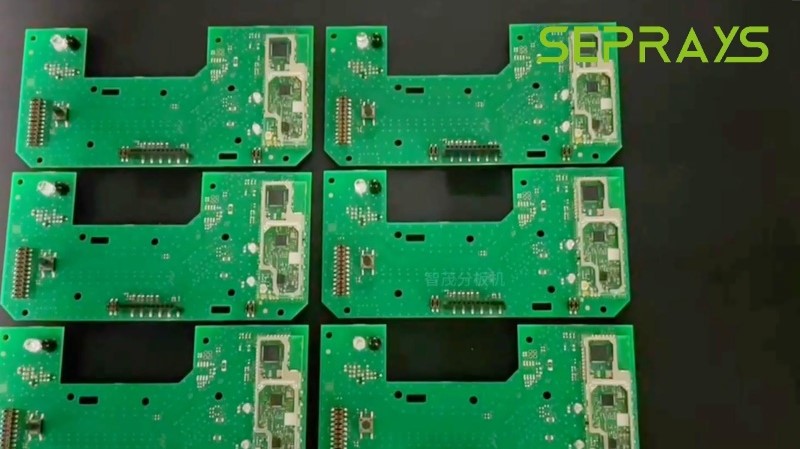

Down-cutting PCB separators are particularly suitable for PCBs with high components, up to 45mm in height. Unlike traditional depaneling methods, they reduce the risk of bending or damaging tall components.

High-component boards often require precise handling. A down-cutting separator ensures a smooth cut while keeping the integrity of sensitive components intact.

💨 Cleaner Dust Collection with Lift-and-Drop Suction

Dust is a major concern during PCB depaneling. The GAM385AT down-cutting separator uses a lift-and-drop suction system to collect dust efficiently. This feature minimizes debris, helping maintain a clean working environment.

Clean dust collection not only improves the workspace safety but also enhances the quality of downstream processes like soldering and assembly.

🔧 Fixture-Free Depaneling System

Traditional PCB separation often needs specialized fixtures. However, the GAM385AT uses a fixture-free system. It combines clamping and cutting to simplify the depaneling process.

This approach saves setup time and increases flexibility. It’s ideal for projects where PCB sizes vary or production batches are small.

📈 Boost Efficiency in Small-Batch, High-Mix Production

Projects with small-batch, high-mix PCBs benefit most from a down-cutting separator. With automatic clamping and cutting, these machines reduce manual labor and increase throughput.

The precision of a down-cutting separator ensures that even complex boards are handled safely. This leads to fewer defects and higher production reliability.

🔹 Reduce Stress and Component Damage

One of the biggest advantages of using a down-cutting separator is minimizing stress on the PCB. The cutting motion is downward, which reduces vibration and prevents micro-cracks in solder joints.

This is essential when working with delicate boards or high-value components. Lower stress levels lead to higher quality and fewer returns.

🛡️ Versatility Across PCB Sizes

Down-cutting separators can handle a wide range of PCB sizes. From small prototypes to larger boards, the fixture-free system adapts quickly.

Manufacturers can switch between different projects without the need for time-consuming adjustments.

🌍 Why Choose Seprays Group?

Seprays Group is trusted worldwide for PCB depaneling solutions.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

If you want cleaner boards, safer operations, and better productivity, the Seprays Milling Cutter PCB Depaneler is your answer.

📩 Contact us today at sales@seprays.com or visit www.seprays.com.

.png)