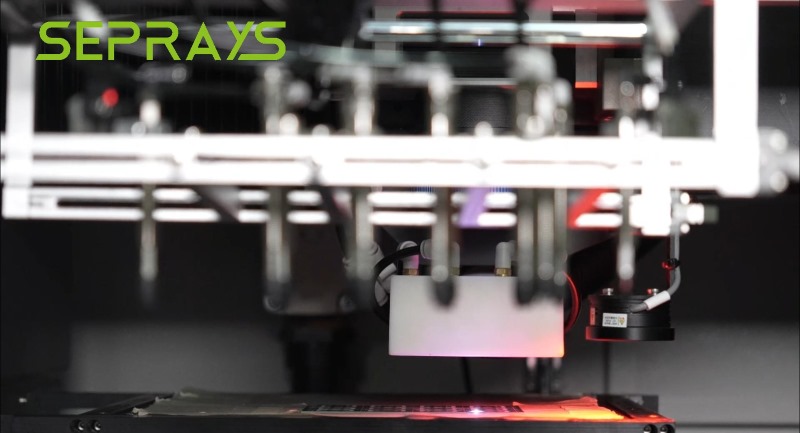

🌟 Laser panel cutting machines are transforming how manufacturers handle PCB separation. Traditional methods like V-cut or routing have served for years, but the demand for precision, cleanliness, and stress-free processes has shifted the focus. Let’s dive into why more and more companies are choosing laser solutions.

🔍 Precision Without Compromise

One of the biggest advantages of laser panel cutting machines is accuracy.

The laser beam follows programmed paths with micron-level precision. This ensures perfect cuts even in complex outlines. No physical tool touches the board, so there’s no risk of misalignment caused by wear and tear.

For industries like medical electronics and aerospace, where even the smallest error matters, this precision is critical.

🛡 Stress-Free Separation

Mechanical methods can create stress points around sensitive components.

Lasers cut without contact, eliminating mechanical pressure on the board. This protects fragile chips, connectors, and thin traces near the edges. Manufacturers working with high-value PCBs trust lasers because they maintain integrity across every separation.

💨 Cleaner, Dust-Free Production

Milling and routing generate dust and particles. These can contaminate circuits or interfere with optical sensors.

Laser panel cutting machines operate without producing debris. The result is a cleaner production environment, reducing post-processing and minimizing the risk of quality issues.

This benefit is especially valued in cleanroom conditions, such as semiconductor and advanced communications manufacturing.

⚡ Flexibility Across Materials

Not all PCBs are created equal. Some are rigid, others flexible, and many combine both.

Lasers adapt to a wide variety of materials, including FR4, ceramics, and flexible substrates. They can handle thin or thick boards without adjusting cutting heads or tools. This flexibility makes lasers a smart investment for manufacturers serving multiple industries.

🚀 Faster Time-to-Market

When speed matters, lasers deliver.

Since there are no mechanical blades to replace or sharpen, downtime is reduced. High-speed laser systems also process complex outlines quickly, making them ideal for high-volume production.

This efficiency directly translates to faster time-to-market — a big advantage in competitive sectors like consumer electronics.

🌍 Sustainable and Cost-Efficient

Lasers are energy-efficient and reduce material waste. Unlike mechanical tools, they don’t require frequent replacement of parts. Over time, this lowers operating costs while supporting sustainability goals.

For global manufacturers aiming to balance cost savings and eco-friendly practices, lasers provide a future-ready solution.

💡 The Key Takeaway

Laser panel cutting machines offer unmatched precision, stress-free operation, and adaptability. They create cleaner production lines, improve efficiency, and reduce long-term costs. That’s why more manufacturers worldwide are choosing lasers as their go-to depaneling solution.

🤝 Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

With proven reliability and global expertise, Seprays helps manufacturers achieve higher yields, better efficiency, and long-term product quality.

📧 If you need support, please contact us today.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)