Seprays-Jayden

Seprays-Jayden

2025-03-14 15:06:31

2025-03-14 15:06:31

36

36

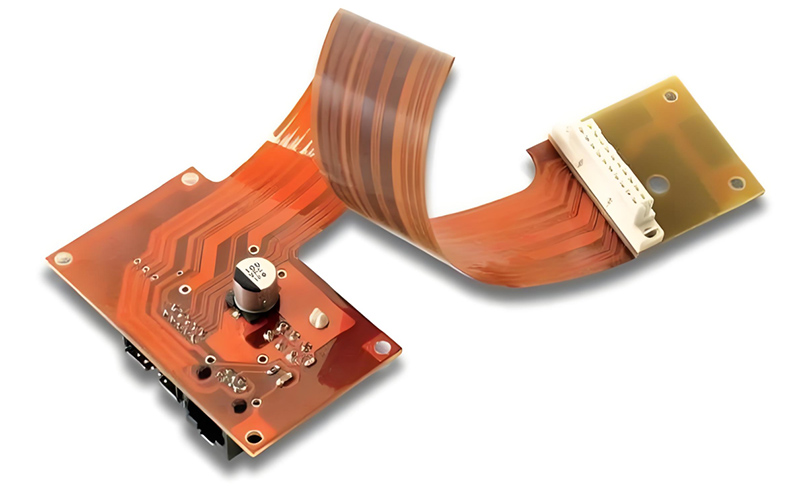

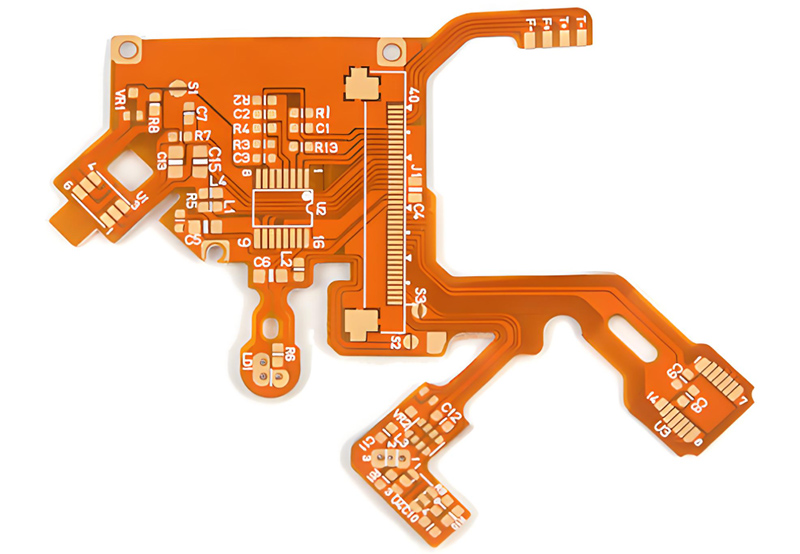

In electronics manufacturing, separating individual printed circuit boards (PCBs) or flexible printed circuits (FPCs) from a larger panel is a crucial step. PCB/FPC punching depaneling is a popular method, offering speed, precision, and cost savings. It helps meet the high demands of modern production while ensuring product quality. This essay explains the benefits, drawbacks, and advancements in punching depaneling, showing why it’s essential in today’s electronics industry.

PCB/FPC punching depaneling is used to separate individual printed circuit boards (PCBs) or flexible printed circuits (FPCs) from a larger panel after manufacturing. This process is crucial in electronics production, where multiple circuit boards are fabricated on a single panel to optimize manufacturing efficiency.

High Speed & Efficiency

Punching separates multiple boards instantly, making it much faster than other methods like routing or laser cutting. Ideal for high-volume production, reducing manufacturing time.

Consistent Quality & Precision

Ensures uniform and accurate cuts every time.Reduces variation and defects, maintaining high product quality.

Low Stress on PCBs/FPCs

Unlike mechanical routing, punching applies minimal force, preventing cracks or component damage. Especially useful for flexible PCBs (FPCs) that require gentle handling.

Cost-Effective for Mass Production

Lower operating costs compared to laser cutting or CNC routing. Once a mold is created, the cost per unit is very low, making it ideal for large-scale manufacturing.

Clean & Burr-Free Edges

Punching produces smooth edges without debris or dust.No need for additional cleaning or finishing processes.

Easy Automation & Integration

Can be fully automated with robotic systems for higher efficiency.Works well in Industry 4.0 smart factories.

Safe & Reliable Process

Reduces the risk of operator errors compared to manual cutting. Consistently performs well in demanding production environments.

Expensive to Set Up

Punching requires custom molds, which can be costly to design and produce. If your PCB designs change often or you make small batches, the cost of making new molds may not be worth it.

Not Very Flexible

Since punching uses a fixed mold, it’s not ideal for boards with changing designs. Every new layout needs a new mold, unlike laser cutting or routing, which can handle different designs without extra tools.

Not for Complex Shapes

Punching works best for simple board shapes. If a PCB has detailed patterns, curved edges, or small cutouts, other methods like laser cutting or routing may be a better choice.

Takes Up Space

Punching machines, especially automatic ones, need a lot of room. If your workspace is small, fitting in this equipment could be a challenge.

Tools Wear Out Over Time

The mold and punch tools can wear out after repeated use, especially in high-volume production. Regular maintenance and replacements are needed to keep the quality consistent, which adds extra costs.

May Damage Very Thin PCBs

Although punching is a low-stress process, extremely thin or fragile PCBs/FPCs can still bend or get damaged if not handled carefully. Proper support is needed to prevent defects.

●High Efficiency, FPCs/PCBAs can be divided into 6 to 8 pieces in one minute.

●The depaneling process ensures a smooth surface and uniform dimensions of the products.

●Low noise and dust-free operation, thereby reducing environmental pollution.

●Low energy consumption, primarily powered by compressed air.

●Reduces the labor intensity for operators.

●Utilizes an automatic lower mold feeding and ejection system for depaneling, with both light curtains and safety doors providing protection, ensuring a very safe operation for the workers.

ZM10T/15T PCB & FPC Punching Cutting Machine presents itself as a highly efficient and advanced solution for the precision processing of Flexible Printed Circuits (FPCs) and Printed Circuit Board Assemblies (PCBAs).

The ZM10TY/15TY PCB/FPC Punching Cutting Machine is designed for efficient and precise processing of Flexible Printed Circuits (FPCs) and Printed Circuit Board Assemblies (PCBAs), echoing the capabilities of its counterparts in the series with several.

The ZM10TS / 15TS PCB & FPC Punching Cutting Machine with a focus on delivering high-performance punching and cutting solutions for Flexible Printed Circuits (FPCs) and Printed Circuit Board Assemblies (PCBAs).

PCB/FPC punching depaneling is an effective method for quickly and accurately separating circuit boards, making it great for high-volume production. While there are some drawbacks, like the cost of molds and limited flexibility for complex designs, its advantages in speed, precision, and ease of automation make it a strong choice. With machines like Seprays’ ZM series, manufacturers can increase efficiency, safety, and productivity in their depaneling processes, helping them meet the growing demands of the electronics industry.

E-mail : sales@seprays.com

Tel : +86-0769-83284766

+86-13925527370

Address : 5th Floor, B2 Building Research Center Songshan Lake Intelligent Valley, Liaobu Town, Dongguan City, Guangdong Province, China