Latest Products

About Seprays

Founded in Taiwan in 1993, Seprays focuses on technological R&D and innovation. In 2002, it established a branch in Dongguan (upgraded and reorganized into a subsidiary in 2013), fully responsible for R&D, production, sales, and after-sales technical training services, ensuring rapid response and comprehensive support to customer needs. To further expand production, in 2003, it purchased nearly 20 acres of land in Zhejiang Province and established a 20,000 square meter modern industrial plant, increasing production capacity and manufacturing capabilities.

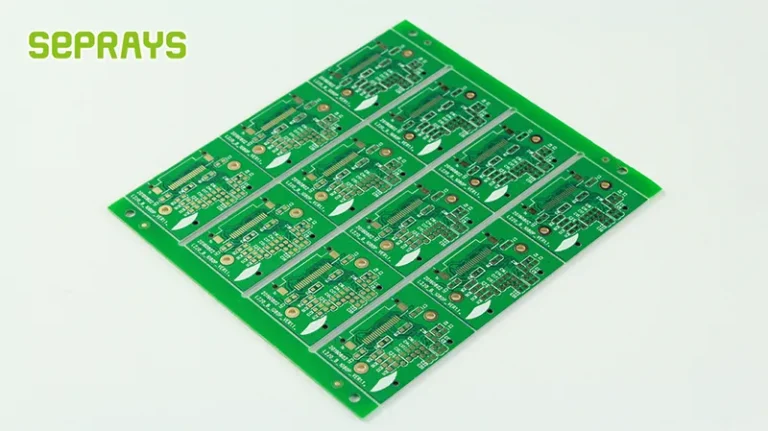

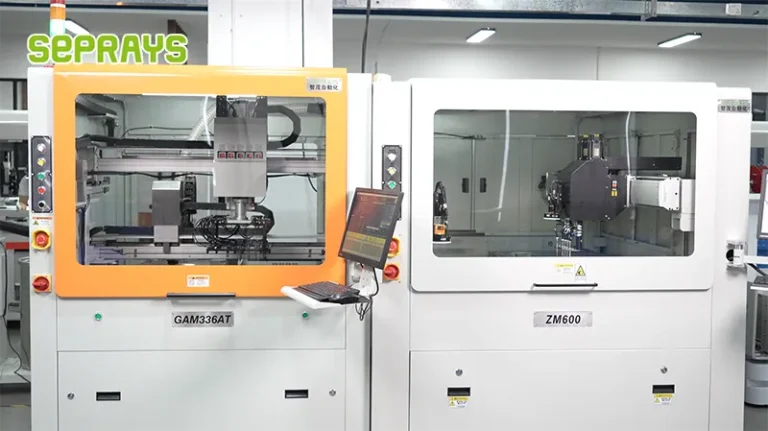

Seprays has been dedicated to the PCB/FPC depaneling field for over 30 years. Its main products include milling cutter depanelers, laser depanelers, V-groove depanelers, and stamping depanelers, as well as automated loading and unloading solutions for the front and rear ends of depaneling, including plate placement. It is a high-tech enterprise integrating R&D, production, sales, and service.

Seprays provides a complete line of equipment services to Fortune Global 500 and China’s Top 500 companies, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, Bosch, China Electronics, Quanta Computer, CRRC Corporation Limited, China Aerospace Science and Technology Corporation, OPPO, and ZTE, as well as small and medium-sized enterprises. Seprays’ complete panel separation lines are widely used in factories both domestically and internationally.

The company is ISO9001, ISO14001, and ISO45001 certified, holds CE certification, and owns over 100 hardware and software patents. It operates two modern factories covering over 26,000 square meters in mainland China and has service locations in nine cities across China, providing nationwide after-sales service. Sales and service locations in 31 countries worldwide provide timely customer service.

Service For Global

PCB Depaneling Total Solution

31

Countries & Regions

32

Years of experience in SMT industrial equipment manufacturing

180+

Patents & Certificates

Partners

Seprays depaneling machines — trusted by over 3,000 industry leaders worldwide.

News

PCB Depaneling Insights & Manufacturing News

Should You Use Laser or Router Depaneling for High-Density PCBs?

Laser or router depaneling for high-density PCBs? This question appears frequently when engineers design compact boards with tight component spacing. As PCBs become smaller and more complex, choosing the right depaneling method directly affects product reliability, yield rate, and long-term manufacturing cost. Many teams initially choose based on equipment price alone. In practice, the real decision often comes down to board structure, component distance to edge, stress tolerance, and production scale. 🔍 The Core Question Behind Depaneling Choice High-density PCBs usually place components close to the board edge. This makes mechanical stress during separation a critical concern. Two common solutions exist: Both methods are widely used in electronics manufacturing. The key question is not which is better overall, but which

Inline or Offline Laser PCB Depaneling — Which to Choose?

This is a common question when manufacturers start using laser depaneling seriously, not just as a lab tool. Both options work. The real issue is where they fit best in your production flow. This article shares practical experience from real SMT lines, not ideal diagrams. 🔍 What “Inline” and “Offline” Really Mean Before comparing, it helps to be clear. Inline laser depanelingThe depaneling system is connected directly to the SMT line. Panels move automatically from upstream processes and continue downstream without manual handling. Offline laser depanelingPanels are loaded manually or via a standalone loader. The machine works independently of the SMT line. The laser technology may be similar. The production logic is not. ⚠️ The Real Pain Points Behind This

When Is V-Cut PCB Depaneling Not Recommended?

V-cut depaneling is fast, simple, and cost-effective—but it is not a universal solution. In real SMT production, many quality issues appear not because V-cut is “bad,” but because it is used in the wrong situations. This article focuses on where V-cut starts to fail, based on production experience rather than theory. ⚠️ The Core Limitation of V-Cut Depaneling V-cut depaneling works by applying mechanical force along a pre-scored groove.That means: When boards or components cannot tolerate that stress, V-cut becomes risky. 🧩 High-Density PCBA: A Common Problem Area V-cut is not recommended when components are placed close to the board edge. Typical risk scenarios: In these cases, depaneling stress can cause: These issues often appear weeks later, not during depaneling.

Can PCB Milling Depaneling Be Automated?

This question comes up frequently when manufacturers move from manual or semi-automatic separation toward higher throughput and more stable quality. The short answer is yes—PCB milling depaneling can be automated. The more useful answer is how far automation really goes, and when it actually pays off. 🤖 What “Automation” Means in PCB Milling Depaneling Automation does not mean just adding a conveyor. In real production, automated PCB milling depaneling usually includes: The goal is not speed alone, but repeatability and reduced human dependency. 🧩 Why Manual Milling Still Exists Many factories still rely on manual or semi-automatic milling depaneling because: Manual systems offer flexibility, but they also introduce operator-to-operator variation, which becomes a bottleneck as volumes rise. ⚠️ Pain Points

Seprays — Your PCB Depaneling Expert.

Because we know that even the best products are only as strong as the people behind them.

That’s why we provide 24/7 expert technical support—whenever and wherever you need it.

.png)