Milling cutter PCB depaneling machine dust collection performance is often underestimated until production problems appear. Fine fiberglass dust, resin particles, and copper debris generated during routing do not just affect cleanliness—they directly influence yield, equipment lifespan, and operator safety. So how effective are modern dust collection systems in real SMT environments?

This article shares practical, experience-based insights from global EMS and OEM production lines, focusing on industrial quality, durability, and long-term operational value rather than specifications alone.

🧠 Why Dust Control Matters More Than It Seems

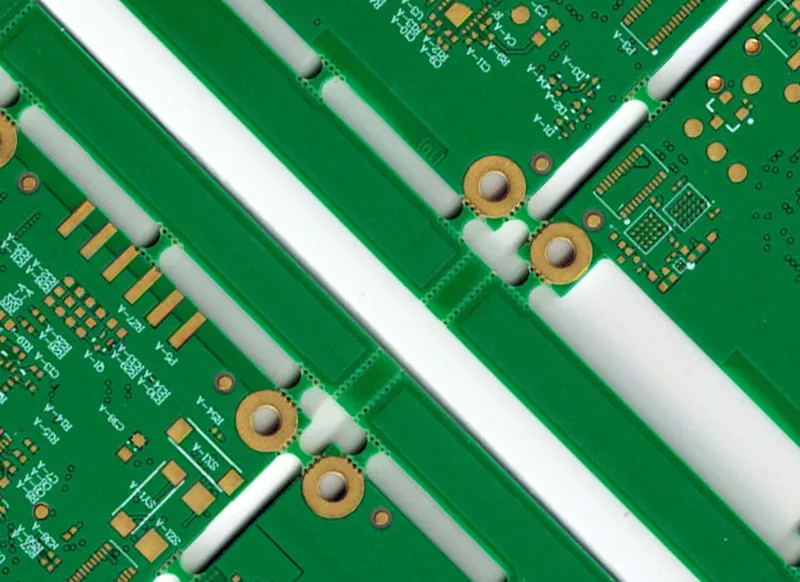

In high-density PCBA production, routing dust creates several hidden risks:

- Conductive copper particles may cause micro short circuits

- Fiberglass dust contaminates connectors and test points

- Residual debris increases post-routing cleaning costs

- Airborne particles accelerate spindle and linear guide wear

Many engineers only notice dust issues after yield drops or maintenance intervals are shortened.

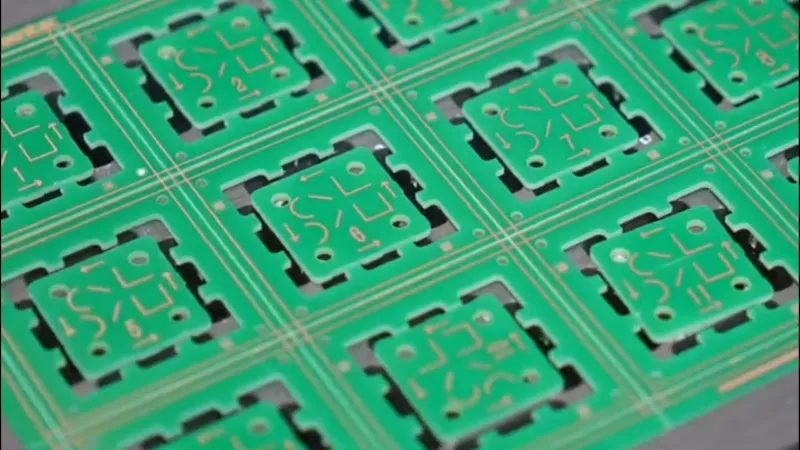

⚙️ How Dust Is Generated During Milling Depaneling

Unlike laser or V-cut methods, milling physically removes material. This creates:

- Coarse chips near the cutting path

- Fine airborne dust from FR4 and resin

- Heat-driven particles, if the extraction is insufficient

An effective dust collection system must handle both heavy chips and ultra-fine particles simultaneously.

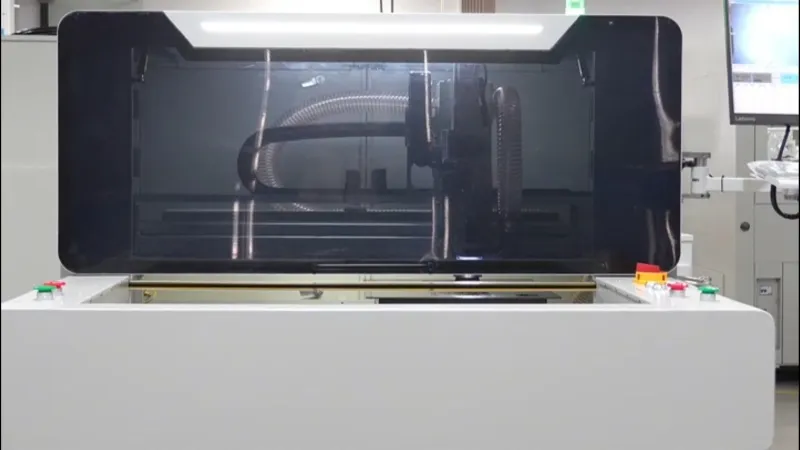

🧩 Design Factors That Define Dust Collection Efficiency

Field comparisons show that dust collection performance depends less on suction power alone and more on system design:

- Nozzle proximity to the cutter tip

- Balanced airflow from top and bottom extraction

- Sealed routing chambers to prevent leakage

- Stable airflow even during high-speed acceleration

Poorly designed systems may look powerful on paper,r but lose efficiency once panels vary in thickness.

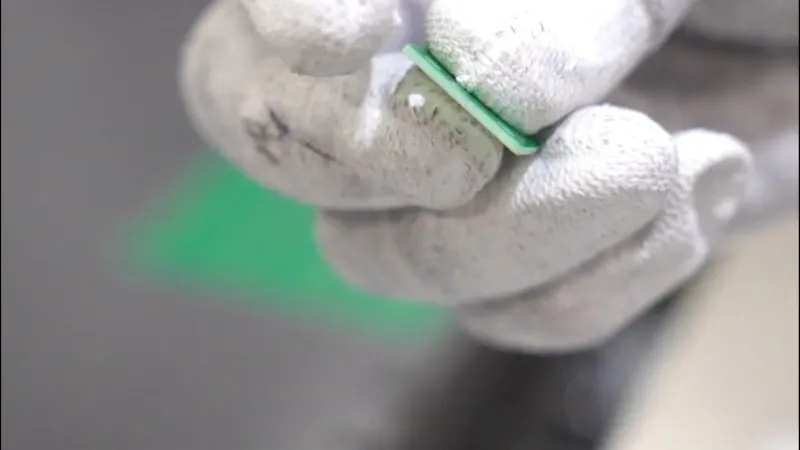

🏭 Case Insight: Medical Electronics Assembly Line

A medical device manufacturer experienced unexplained contamination during functional testing. Root cause analysis traced the issue to fine routing dust settling inside connectors. After upgrading to a milling cutter PCB depaneling machine with optimized dual-channel dust extraction, contamination-related failures dropped by over 30% within two months.

📉 Cost Analysis: Dust Collection vs. Hidden Expenses

While advanced dust extraction adds initial cost, the long-term balance often favors better systems:

- Reduced downtime for cleaning

- Longer spindle and bearing life

- Lower risk of ESD and conductive debris

- Improved compliance with clean production standards

Several EMS operators reported that dust-related maintenance costs exceeded the price difference between basic and industrial-grade extraction systems within the first year.

🛠️ Practical Recommendations from the Field

Engineers managing high-mix or high-value PCBAs commonly suggest:

- Inspect dust flow during actual cutting, not idle tests

- Replace filters based on pressure differential, not time

- Ensure extraction performance remains stable at full RPM

- Treat dust control as part of process quality, not housekeeping

Dust collection should be evaluated as a process safeguard, not just an accessory.

🌍 Aligning with Global SMT Production Expectations

In regions with stricter environmental and workplace regulations, effective dust control is increasingly a baseline requirement. Clean routing processes also support traceability, reliability, and consistency—key expectations for automotive, medical, and industrial electronics.

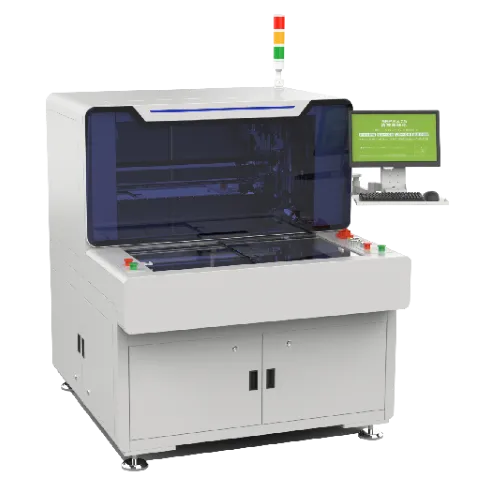

💬 Why Choose Seprays Group?

Seprays Group designs milling cutter PCB depaneling systems with industrial-grade dust collection engineered for long-term stability, not short-term performance. Our approach focuses on protecting product quality, equipment durability, and clean production environments across demanding SMT lines.

If you would like to evaluate dust control performance for your specific application, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)