説明

| モデル | GAM336AT |

|---|---|

| 有効切断サイズ | 450*420mm |

| 載荷方法 | トラック納入 |

| 搬入方法 | コンベアベルトやトラック納入 |

| 移動方向 | 左または右 |

| 切削機能 | Tweeningを直線、L形、U形状、円弧 |

| 工程表" | デュアルテーブル |

| 繰り返し精度 | ±0.01mm |

| 切断精度 | ±0.05mm |

| 最大移動速度 | XY:1000mm/sec、Z:800mm/秒 |

| 主軸回転速度 | MAX:60000rpm(調整可能) |

| ツールタイプの変更 | オートツールの変更 |

| Safety protectionSafety | y light curtain |

| 切削速度 | 1-100mm/s |

| 経営システム | Windows10 |

| The program teaching method | 直感的な教育によるCCDカラー画像入力 |

| 制御方法 | 精密多軸制御システム |

| XYZ軸駆動モード | ACサーボモーター |

| サイズのミリングツール | 0.8-3.0mm |

| 電圧/電源 | AC220V50/60Hz4KW単相 |

| 空気圧の圧力の要件 | 0.6MPa220L/min |

| 外形寸法(W*D*H) | 1947年*2096*1820mm |

| 重量 | 1145kg |

| 集塵機 | TS300L |

Product Introduction

A single transfer is flexible in application. Users can set the system to pick and place PCBA at 0–180 degrees to meet the requirements of front-end and back-end process docking.

Self-feeding, cutting, milling cutter replacement, finished product discharge, waste collection, and fully automated production operations.

Finished product discharge can be selected from belts, tracks, and fixtures.

CCD visual alignment compensation correction to ensure cutting accuracy.

The high-speed ESD automatic tool change spindle automatically discharges static electricity generated during the board separation process, reducing potential damage to the PCBA.

Patented floating brush structure can perform segmented deepening of milling cutters.

6HP high-suction dust collector, equipped with negative pressure detection to remind cleaning filter bags.

Windows 10 operating system. Software automatic development, continuous function upgrades.

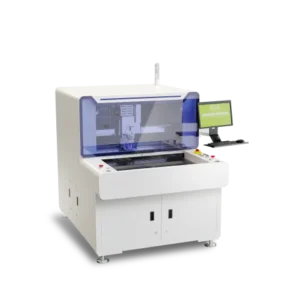

の GAM 336AT In-Line Automatic PCB Router Depaneling Machine by SEPRAYS is a high-performance solution designed to optimize PCB separation with maximum flexibility and precision. Featuring a 0–180° pick-and-place function, it seamlessly adapts to various upstream and downstream processes in your SMT production line.

With its integrated CCD vision positioning system, the GAM 336AT ensures accurate cutting alignment. A high-speed, ESD-safe spindle with automatic tool-change capability reduces static-related damage, while the patented segmented brush design extends tool life by dividing the blade into multiple usable sections.

Optional unloading methods include belt, conveyor, fixture, or custom tray placement. For higher output needs, dual-spindle models like the GAM336AD and GAM336ALD are available.

Optional features: cutting detection, laser height checking, barcode reader, tool diameter detection, and custom MES integration.

製品の特徴

CCD Vision Automatic Calibration System

- Equipped with a high-speed CCD vision automatic calibration system

- Cutting path simulation assists programming, ensuring accurate cutting paths

- Full-sheet scanning and offline programming improve path editing efficiency

High-speed cutting spindle

- Imported high-speed, high-precision spindle

- Low cutting stress, smooth board edges, and high precision

- High-precision spindle speed of 80,000 rpm/min

High utilization rate

- With over 32 years of independent software development, the board splitter utilizes independently developed software, ensuring stability and reliability, eliminating board defects caused by bugs.

Exclusive Features

- The depaneling machine features a one-piece welded design for stability and high strength.

- Made of cast aluminum, it resists oxidation, deformation, and deflection, ensuring a long lifespan and guaranteed precision.

Dust collection eliminates dust hazards.

- Utilizes a high-power dust collector.

- HEPA-rated dust filtration.

- Equipped with a negative pressure detector to continuously monitor dust collection status.

- Equipped with a floating brush (invention patent number ZL201721620742.X) to enhance dust collection efficiency.

Centralized control system management

- Optional central control system: Centralized management and real-time monitoring via IP network.

- Remote device management: Remote monitoring via mobile app.

Application Cases

Automatic PCB Loader + GAM336AT Online CCD Vision PCB Depaneler + Sorting and Plating Machine + AGV Handling Complete Line Case

FAQ

どのサービスを展開していく。

We provide one-stop automated PCB depaneling solutions: laser, routing, punching, and V-CUT.

すことができる機械の取扱いの異なる厚さの板?

Yes, our machines are designed to handle various PCB thicknesses. We can provide customization and options to ensure smooth processing of both rigid and flexible boards.

どのような研修だす機械?

まで、一貫して展開していますのオンサイトトレーニングを覆う機械の操作、保守、およびトラブルシューティング. また継続的な技術サポート、電話やメール.

何を販売後のサービスができるの?

● Exclusive service:

We will give users feedback within 10 minutes on any problems they encounter when using the device, and establish a 1V1 exclusive after-sales service group for users.

● Remote service:

Provide users with a 7/24-hour hotline based on feedback on fault information, analyze, locate, and solve the fault through remote telephone support, remote login, and other methods.

● On-site service:

Arrive at the work site within 8 hours and solve the problem within 1 working day. 2-4 days of training on equipment safety, type operation, and application. Any breach of contract will be handled by the contract provisions.

● Service locations:

して販売-サービス支援31カ国-地域、海外への対応お客様の現在および将来のニーズとが可能です。

● Benchmark service:

フォローアップコースの後、それぞれの訪問についてのビデオチュートリアル+電話の指導部品の交換、機器メンテナンスフォ月です。 今後もユーザーの収集ご提案を継続的に更新および繰り返し処理を実行し、ソフトウェアの向上、ユーザーの生産効率と品質で、生涯メンテナンス。

適用分野

弊社のPCB depaneling解を中心に幅広い産業分野にご利用いを必要とする高精度-高効率基板を分離します。

主なアプリケーション分野:

- Consumer Electronics – Smartphones, tablets, laptops, and wearables.

- Automotive Electronics – PCBs for ADAS, infotainment systems, and EV components.

- Medical Devices – Precision electronics in diagnostic and monitoring equipment.

- Telecommunications – Network and communication hardware.

- Industrial Electronics – Control systems, automation equipment, and IoT devices.

- Aerospace & Defense – High-reliability PCBs for avionics and military applications.

Our PCB depaneling solution supports both PCB milling machines and routing processes, providing high-precision CNC cutting for complex PCB shapes.

📩 Contact us now and discover why over 3,000 leading companies trust SEPRAYS for their PCB depaneling needs.

.png)

レビュー

レビューはまだありません。