Новости

Analysis of the top ten PCB depaneling machine brands: global and Chinese market structure

The PCB depaneling machine market is evolving rapidly.Driven by demand from electronics, automotive, and 5G sectors, global brands are competing on precision, automation, and service quality.Let’s explore the market landscape, leading players, and the rise of Zhimao Technology. 📈 1. Global Market Overview Market Size and Growth In 2023, the global PCB depaneling machine market reached USD 167 million.By 2030, it’s expected to grow to USD 273 million, at a CAGR of 7.5%. The Asia-Pacific region dominates the market, contributing over 40% of global demand.China, Japan, and South Korea are the key consumption hubs, thanks to the electronics manufacturing cluster effect. Top 10 Global Brands (2024–2025) According to the CNPP brand rankings, the top brands include: Competition Focus & Regional Trends 🚀 2. Zhimao Technology: A Rising Force in Global Markets Market Share and Performance Competitive Pricing Zhimao’s GAM series automatic depaneling machines are priced between $35,000–$60,000—about 20–50% lower than comparable European or U.S. brands. Technology Advantages Core Strengths: Full-Chain Competitiveness 🔮 3. Future Trends & Strategic Focus Smart Technology & Integration Market Expansion Areas ❓ 4. FAQs About Zhimao Depaneling Machines Q1: What industries use Zhimao’s board splitters?A: Consumer electronics, automotive systems, and 5G infrastructure—especially high-precision, multi-connection PCBs. Q2:

The Working Principle of PCB Stamping Depaneling Machine and How to Choose a Suitable One

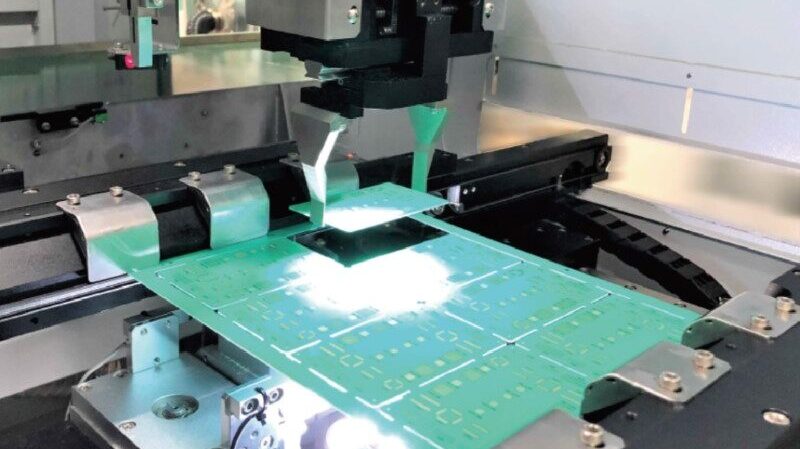

A PCB stamping depaneling machine offers speed, precision, and high-volume capacity.It’s a go-to solution for manufacturers looking to separate PCB panels quickly and cleanly.But how exactly does it work? And how do you choose the right one? Let’s break it down. ⚙️ How a PCB Stamping Depaneling Machine Works The working principle of a PCB stamping depaneling machine is based on custom die punching technology.No matter if it uses a servo or electric cylinder, the process remains the same. 1. 🧰 Custom Tooling A custom steel mold is created to match the PCB’s V-cut or stamp-hole layout.The blade shape matches the board path precisely.This ensures clean separation without damaging the circuits. 2. 📍 Precise Positioning Before cutting, the PCB panel is fixed in place.This is done using mechanical clamps or vacuum suction.The system uses mechanical holes or optical marks to achieve alignment and ensure a perfect match with the mold. 3. 🧨 High-Force Separation With a single downstroke, the machine applies tons of pressure.The connecting sections are sheared instantly—clean and sharp.A conveyor or robotic arm then removes the separated boards. 📈 Benefits and Limitations of Stamping ✅ Key Advantages: ⚠️ Things to Consider: 🔍 How to Choose the Right PCB

Auto V-Cut Depaneling Machine: Share Your Best Practices for Long-Term, High-Volume Production

An auto V-Cut depaneling machine is essential for electronics manufacturers working with large volumes of PCBs.If your goal is clean cuts, long-term consistency, and reduced labor costs, this tool makes it possible. Today, we explore best practices to get the most out of your auto V-Cut depaneling machine. 🔄 Keep Production Running Smoothly In high-volume production, downtime hurts.Make sure your machine is set up for continuous operation.Use dual conveyor or inline feeding systems to maintain flow. Schedule regular maintenance windows.Clean the blade and guide rail.Replace dull blades on time to avoid rough cuts or board damage. 🛠️ Focus on Blade Quality and Settings Use high-hardness blades for a long lifespan.Carbide or diamond-coated blades work well for tough FR4 materials. Check blade height, angle, and pressure regularly.A slight misalignment can affect the quality and shorten blade life.Set proper V-groove depth on your PCB design to reduce stress on components. 📏 Reduce Stress on Components The benefit of auto V-Cut depaneling is minimizing stress on fragile parts.Mount sensitive components away from the V-cut line.Use support fixtures when necessary. If your boards have LEDs, connectors, or large capacitors near the groove, slow down the feed rate.A slower feed offers better control and protects

PCB Depaneling Methods and Their Characteristics

PCB depaneling is a critical process in electronics manufacturing. It directly affects board quality and component reliability. This article analyzes seven common depaneling methods: manual breaking, die cutting, sliding-type depaneling, guillotine cutting, saw blade separation, milling (router) depaneling, and laser cutting. 1. Manual Depaneling Manual depaneling includes two types: by hand or with tools such as pliers or fixtures. Using fixtures improves efficiency compared to cutting with pliers. This method is often referred to as manual breaking. Advantages: Disadvantages: Manual depaneling is best for “stamp hole” connected PCBs with low-stress connections. For other connection types, this method is not advised. 2. Die Cutting Die cutting uses specialized molds for fast, batch depaneling. It’s ideal for V-cut connected PCBs in medium production volumes. Advantages: Disadvantages: 3. Sliding vs. Cutter Wheel Depaneling Both methods are suitable for V-cut PCBs. Sliding Type: Cutter Wheel Type: Advantages: Disadvantages: 4. Guillotine Depaneling This method is similar to a paper cutter, using a straight blade to cut through V-cut PCBs. Advantages: Disadvantages: 5. Saw Blade Depaneling Uses high-speed rotating blades (e.g., diamond or carbide) to cut PCBs. Works for both V-cut and stamp hole panels. Advantages: Disadvantages: 6. Milling (Router) Depaneling Also known as CNC depaneling

A Deep Dive into the GAM 320A Automatic PCB Router Machine

The GAM 320A automatic PCB router machine is built for manufacturers who demand precision, speed, and reliability. It’s a compact, high-performance router that fits perfectly into modern SMT production lines. If you’re working with small or mid-sized PCBs and need clean, accurate cuts, this machine delivers. ⚙️ Precision Engineering That Performs The GAM 320A is powered by a high-speed spindle motor.Cutting precision reaches ±0.01 mm.Repeatability is locked at ±0.005 mm.This means clean edges, no burrs, and consistent quality. Its rigid frame reduces vibration, keeping every cut stable and sharp—even at high speeds. 🔄 Dual Table for Continuous Production Dual working platforms allow for loading and unloading at the same time.While one board is being cut, the next one is being placed.This reduces downtime and increases efficiency. It’s an ideal setup for manufacturers with growing production volumes. 📷 Vision System with Smart Positioning The machine uses a high-resolution camera for mark recognition.PCBs are aligned automatically—no manual adjustment needed.It saves time, reduces human error, and improves accuracy. With just a few clicks, you’re ready to run the next batch. 🛠️ Built for Flexible Production The system supports PCB sizes up to 350mm x 300mm.Multiple cutting depths and routing shapes are possible.The fixture

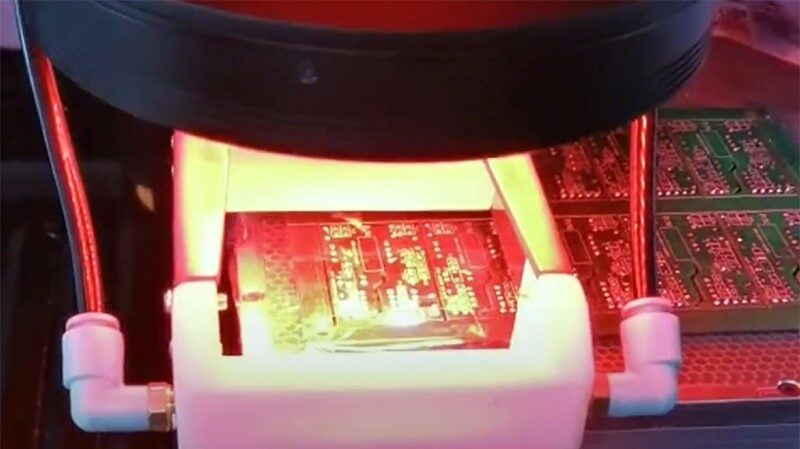

Fixture cost is reduced to zero! Seprays GAM380AT fully automatic PCB depaneling machine sets off a small batch revolution

01—The century-old problem of small batches of PCBs: the tyranny of fixtures Customization fees suck blood: each new board costs more than ¥3000, and 20 orders cost 60,000? Changing lines is like moving: 4 hours to adjust the machine, to meet the delivery deadline, the production line is shut down, and a penalty is paid Warehouses become graveyards: piles of fixtures occupy 30 square meters of prime workshops Until this equipment appeared – Seprays GAM380AT online PCB milling cutter board splitter (Actual photo of the GAM380AT machine in action: the bottom milling cutter accurately cuts the PCB board) 02—Three major black technologies kick “fixture hegemony” into the historical trash can Black technology 1 The adaptive pneumatic gripper eliminates the need for permanent fixtures. Directly grab the edge of any shape PCB and fix it From small PCB Bluetooth modules to 30cm industrial control motherboards Actual benefit: A factory cuts 50 samples, saving 150,000 yuan in fixture fees and 280,000 yuan in storage fees per year Black Technology 2 Changing lines is like watching Douyin | 1 minute to cut and mass produce Put the PCB board on the track → Scan the code to call the program → Press the

.png)