Specifications

| Модель | GAM360AT |

|---|---|

| Допустимый размер резки | 600*500mm |

| Способ загрузки | Отслеживание доставки |

| Способ разгрузки | Belt delivery or track delivery |

| Transfer method | Vacuum nozzle absorption |

| Направление движения | Слева направо или справа налево |

| Cutting function | Tweening to a straight line, L shape, U shape, Circle, Arc |

| Таблица процессов | Single table |

| Repeat precision | ±0,01мм |

| Cutting precision | ±0,05мм |

| Максимальная скорость перемещения | XY: 1000 мм/сек, Z: 800 мм/сек |

| Max’s moving trip | X: 1040mm, Y: 655mm, Z: 90mm |

| Скорость вращения шпинделя | МАКС: 60000об/мин (регулируется) |

| Тип смены инструмента | Автоматическая смена инструмента |

| Cutting speed | 1-100mm/s (Adjustable) |

| Operating system | Windows 10 |

| Program teaching mode | Intuitive teaching by CCD color image input |

| Program backup | USB data transfer |

| Control method | Прецизионная многоосевая система управления |

| XYZ axis driving mode | AC Servo motor |

| Size of milling tool | 0,8-3,0мм |

| Требуемое напряжение / Мощность | AC220V 50/60 Гц 4 кВт Однофазный |

| Требования к пневматическому давлению | 0.6MPa, 200L/min |

| Размеры (Ш* Г*В) | 2309*1606*1717mm |

| Вес | 930kg |

| Collector | TS300L |

Введение продукта

A single workstation performs both cutting and circuit board placement, increasing productivity.

The vision camera features autofocus, eliminating the need for manual focus adjustment.

A high-speed spindle reduces cutting stress and achieves high precision, while an automatic tool changer enables automated operation.

The standard dust collector features dust detection and alarm functions to ensure effective dust collection.

MES connectivity allows for the integrated management system integration of production data and monitoring of equipment status.

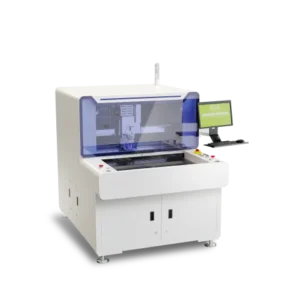

В GAM360AT PCB separator is a high-performance, fully automatic PCB depaneling machine designed for precise and efficient board separation. From automatic loading, vision-based alignment, high-speed cutting, to smart unloading, в GAM360AT PCB separator streamlines your entire process while ensuring quality and repeatability.

A Система позиционирования CCD vision allows for offset correction and alignment, which guarantees millimeter-level cutting accuracy. The GAM360AT PCB separator is equipped with a high-speed spindle featuring an auto tool-change function, minimizing static-related damage to sensitive PCBAs during processing.

Our patented flexible cleaning brush allows segmented use of the milling tool, significantly extending tool life. For higher throughput, Seprays also offers dual-spindle PCB separators, включая GAM320AD, GAM330AD, и GAM340AD, tailored to your production scale.

Optional features include a clamping module, laser height checker, barcode reader, tool diameter detector, and MES integration.

Choose the GAM360AT PCB separator for reliable, scalable, and precision-driven PCB depaneling.

Характеристики

Laser Height Measurement

- A laser height measurement module is installed to check whether the PCBA is placed at the correct height when placed in the jig. This prevents misalignment and damage during separation due to improper placement of the PCBA or small board fragments in the jig.

Быстрая Замена Линии

- Recall existing programs to avoid jig errors, enabling quick program recall and line changeover.

High Utilization Rate

- With over 30 years of independent software development, the depaneling machine utilizes stable and reliable software, eliminating board defects caused by bugs.

Exclusive Features

- The depaneling machine features a one-piece welded design for stability and high strength.

- Made of cast aluminum, it resists oxidation, deformation, and deflection, ensuring a long lifespan and guaranteed precision.

Dust collection eliminates dust hazards

- Utilizes a high-power dust collector.

- HEPA-rated dust filtration.

- Equipped with a negative pressure detector to continuously monitor dust collection status.

- Equipped with a floating brush (invention patent number ZL201721620742.X) to enhance dust collection efficiency.

Centralized control system management

- Optional central control system: Centralized management and real-time monitoring via IP network.

- Remote device management: Remote monitoring via mobile app.

Примеры применения

The GAM360AT in-line, ultra-large PCB splitter can be connected to loaders, unloaders, and PCB collectors at the front and rear ends.

.png)

评价

目前还没有评价