规格

| 项目 | ZM30-AP |

|---|---|

| 外形尺寸 | 长*宽*高=950*920*1750MM |

| 外形 | 立式 |

| 设备重量 | 220KG |

| 颜色 | 电脑白 |

| 设备功率 | AC220V 300W |

| PCBA board separates direction | X or Y one-way can be divided into boards, and the angle can be arbitrarily adjusted |

| 工作气压/管径 | -20~50 ℃ |

| 零件离切割线最小距离 | 大于或等于1.5mm |

| 最大最小分板长度 | 250*250mm 12*12mm |

| PCB板元器件最高高度 | PCBA正面反面限高总和小于15MM |

| 误操作防护 | grating sensor, safety door cover, and software multi-protection. |

| Parameter settingAccording | go to the size of the V-slot touch screen, direct input |

| 存储模块 | 可存储50组程式 |

| 分板效率 | 2s/刀 |

| 刀片角度 | 10-30度(可选择) |

| 更换时间 | 15分钟 |

| 导轨丝杆 | 上银导力丝杆+三轴移动平台 |

| Maximum length and width of the assembly line | 650mm*250mm(可订制) |

| Thickness of the board | 0.4-3.5mm |

| 断电断气功能 | 有 |

| 工作方式 | manual release line, slitting, and feeding boards |

| 适用范围 | 插件/贴片后PCB板的V槽去板边分板 |

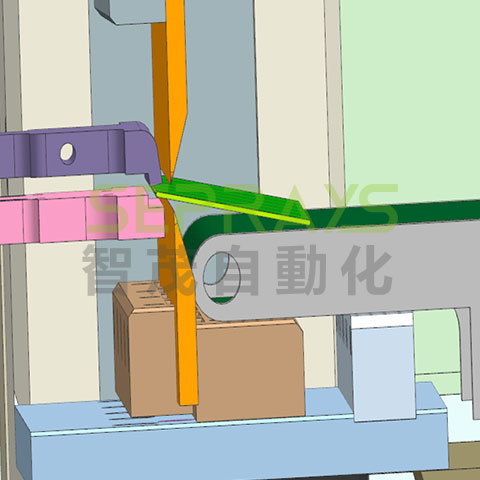

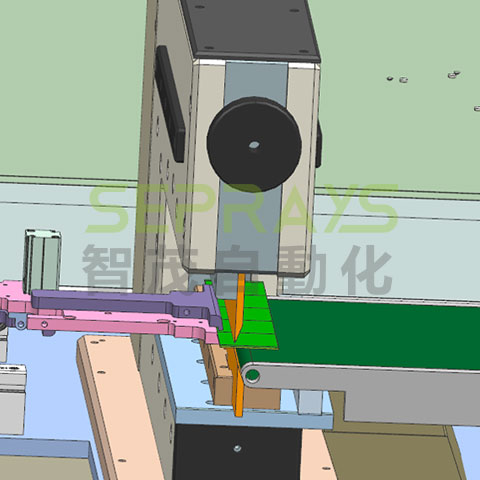

The ZM30-AP V-groove depaneling machine is a fully automated solution developed by SEPRAYS for efficient, precise, and safe V-groove PCB depaneling. From automatic feeding to cutting and discharging, this advanced system minimizes manual intervention and significantly boosts production efficiency.

Equipped with precision positioning technology, the ZM30-AP V-groove depaneling machine ensures exact alignment and cutting accuracy, protecting PCBA components and enhancing overall product quality. Its flexible material handling system—using suction cups and belt conveyors—accommodates a variety of PCB shapes and sizes with ease.

Integrated waste disposal keeps the workspace clean and streamlines production. Designed for continuous cycle operation, it’s ideal for high-volume manufacturing environments where speed and consistency are critical.

.png)

评价

目前还没有评价