规格

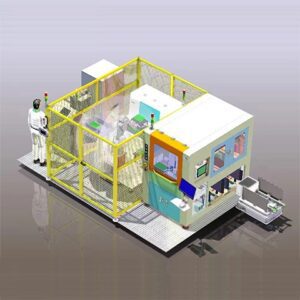

GAM310AT — 小型PCB板分板专家

紧凑设计:对比标准机型,GAM310AT的机身长度缩短了45%,更适合空间有限的生产环境。

快速切割:Cycle time低于10秒,大幅提升生产节拍,满足快速生产需求。

Size Adaptation: With a focus on small PCB board processing, the system achieves an effective cutting size of 200×180mm, ensuring both cutting accuracy and operational efficiency.

Front-end and back-end docking: Seamlessly integrated into the production line, the front end can be connected to the loading and unloading machine, and the back end of the docking pendulum machine, to realize a fully automated workflow.

GAM630V — 外观品质的守护神

Precision Inspection: Utilizes advanced vision technology to perform high-precision inspection of solder joints, component arrangement, surface defects, etc., on PCB boards.

自动分类:即时区分合格与不合格产品,通过OK/NG分离功能,确保产品质量控制,减少后续人工筛选步骤。

GAM620H — 智能摆盘解决方案

自动化TRAY处理:自动完成TRAY的摆放与更换,提升工作效率,减轻人工负担。

智能识别:具备空满TRAY前方取料功能,通过智能识别系统,准确判断并自动处理,确保作业流畅。

整体优势

Flexible Configuration: GAM310AT, GAM630V, and GAM620H can be freely combined according to the actual production requirements, constituting a highly efficient small PCB board processing line.

Quality Assurance: From depaneling, inspection, to board placement, each step incorporates advanced technology and strict quality control to provide customers with stable and reliable production support.

Cost Optimization: Reduce labor costs through high automation, and at the same time, improve production efficiency and yield rate, which brings long-term cost savings and benefits to the enterprise.

应用领域

Suitable for PCB post-processing in consumer electronics, communication equipment, medical electronics, automotive electronics, and other fields.

合作邀请

我们诚邀您亲身体验这一高效、智能的PCB后处理解决方案。无论是提升现有生产线的性能,还是规划新建产线, SEPRAYS智茂 都将为您提供专业的技术支持与定制化服务。 立即联系我们! 共创智能制造新篇章!

.png)

评价

目前还没有评价