规格

| 项目 | GAM386AT |

| Cutting Range | 350 × 300 mm |

| Loading Method | Rail conveyor |

| Unloading Method | Belt conveyor or rail conveyor |

| Transfer Method | Vacuum nozzle adsorption transfer |

| Flow Direction | 从左到右或从右到左 |

| Cutting Functions | Straight line, L-shape, U-shape, circle, arc |

| Worktable | Dual worktables |

| Repeat Accuracy | ±0.02 mm |

| Cutting Accuracy | ±0.05 mm |

| Max. Moving Speed | X, Y: 1000 mm/s; Z: 800 mm/s |

| Spindle Speed | Max: 80,000 rpm adjustable |

| Spindle Tool Change | Automatic tool change |

| Broken Tool Detection | Equipped |

| Cutting Speed | 1–100 mm/s |

| Operating System | Windows10 |

| Programming Method | CCD image intuitive teaching input |

| Control System | 精密多轴控制系统 |

| XYZ Axis Drive | AC servo motor |

| Applicable Cutter Size | 0.8–3.0 mm |

| Power Requirement | AC220V, 50/60Hz, 4 kW |

| Air Requirement | 0.6 MPa, 200 L/min |

| Dimensions (L×W×H) | 1850 × 1500 × 1820 mm |

| 设备重量 | 800 kg |

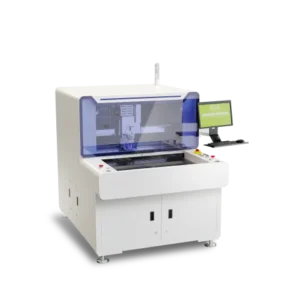

Product Introduction

-

Supports PCBs up to 75mm in height – Ideal for boards with tall top-side components.

-

High-speed CCD vision calibration – Ensures precise alignment and cutting accuracy.

-

Dual worktables with movable cover plate – Minimize spindle idle time while loading and unloading boards.

-

Flexible single transfer system – Adjustable from 0° to 180° to seamlessly connect with upstream and downstream processes.

-

High-speed ESD automatic tool changer – Prevents PCBA damage from static electricity.

-

Brush lift dust collection – Brush attaches to the jig plate during cutting, significantly improving dust removal efficiency.

Product Features

-

CCD Vision Calibration

High-speed CCD vision automatic calibration system ensures cutting accuracy.

Cutting path simulation assists programming, while full-sheet scanning and offline programming enhance editing efficiency. -

Quick Line Changeover

Easily recall existing programs to prevent fixture errors, enabling fast program recall and efficient line changeovers. -

High Software Reliability

Backed by 30+ years of independent software development, ensuring stability, reliability, and defect-free operation.

Exclusive Advantages

-

Robust Construction

One-piece welded frame delivers stability and strength. Cast aluminum body resists oxidation, deformation, and deflection for long-lasting precision. -

Advanced Dust Collection

Equipped with a high-power dust collector, HEPA filtration, and a negative pressure detector for real-time dust monitoring.

Patented floating brush (Patent No. ZL201721620742.X) further enhances dust removal efficiency. -

Centralized Control

An optional central management system enables real-time monitoring via an IP network.

Remote device management is available through a mobile app for convenient control anytime, anywhere.

The GAM386AT Automatic PCB Bottom Router Machine is ideal for PCBA products with tall components, such as those used in consumer electronics, automotive electronics, and communication devices. With its undercutting design, CCD vision alignment, and dual worktables, it delivers precise routing and higher efficiency. The GAM386AT Automatic PCB Bottom Router Machine integrates smoothly into automated production lines, offering reliable performance, flexible transfer options, and excellent dust collection for a cleaner, safer process.

Contact Us for Pricing & Details

Contact Us for Pricing & Details

Email: sales@seprays.com

WhatsApp: +86-18929266433

Our PCB depaneling solution supports both PCB milling machines and routing processes, providing high-precision CNC cutting for complex PCB shapes.

.png)

Contact Us for Pricing & Details

Contact Us for Pricing & Details

评价

目前还没有评价