规格

| 项目 | ZM30-A |

|---|---|

| 外形尺寸 | 1500*800*1500mm |

| 外形 | 立式 |

| 设备重量 | 300KG |

| 颜色 | 电脑白 |

| 电源 | AC220V 1000W |

| 环境要求 | 清洁干燥环境,避免潮湿或高温 |

| 工作气压/管径 | 大于0.6MP/8mm |

| 零件离切割线最小距离 | 大于或等于1.5mm |

| 最大最小分板宽度 | 300mm*300mm / 12*12mm |

| 进板口调节 | 前侧固定,后侧活动调节 |

| PCB板元器件最高高度 | PCB反面零件限高20mm,正面限高35mm |

| 参数设置 | According to the size of the V-slot touch screen, direct input |

| 存储模组 | 可存储50组程式 |

| 刀片 | Japan imported a high-speed steel knife |

| 刀片角度 | 10-30度(可选择) |

| 刀模精度 | 0.1mm |

| 分板效率 | 15s/pcs(200*150mm)标准速度切8刀为参照 |

| Maximum length and width of the assembly line | 650mm*250mm |

| 分板速度 | 0-800mm/s |

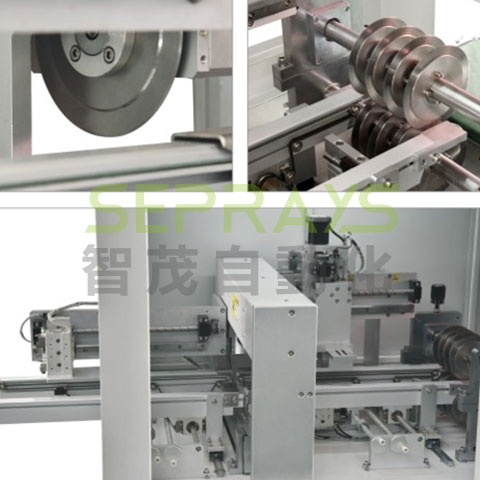

| 吸盘机械手运动控制方式 | 步进马达+导轨+皮带传动 |

| 吸尘方式及功率 | 刀组下吸尘1500W |

| 分板厚度 | 0.4-3.5mm |

| 误操作防护 | triple protection of grating, sensor, and software. |

| 安全防护 | 急停 |

| 断电断气功能 | 有 |

| 自检功能 | power-on time monitoring, capacity monitoring, equipment failure information, and an automatic elimination system |

| 机体主要部份 | 送板机(流水线),吸盘,三轴移动分板平,吸尘器 |

| 工作方式 | automatic robot online slitting and feeding boards |

| 适用范圉 | 插件/贴片后PCB板的双方向V槽 |

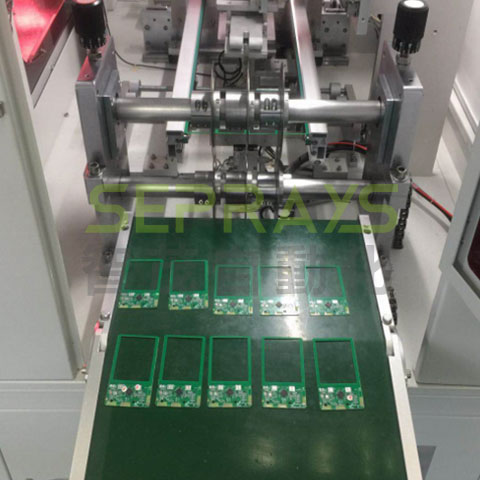

SEPRAYS智茂 specifically engineered the ZM30-A V-groove depaneling machine for high-precision depaneling of PCBA boards after component insertion.

Designed to protect delicate components during the cutting process, it enhances safety while boosting downstream production efficiency.

This machine features a dual-knife cutting mechanism, enabling fast and accurate separation through multiple V-groove tracks. With optional automation modules—including automatic feeding, slitting, and board receiving—the ZM30-A V-groove depaneling machine ensures smooth, operator-friendly performance that significantly increases throughput.

Its configurable parameters allow for fine-tuned operation, while multi-head tooling enables quick and consistent slitting across multiple board groups. The separator also supports automatic output and docking with subsequent systems, ensuring uninterrupted workflow across your production line.

.png)

评价

目前还没有评价