Specifications

| Model | ZM30-AP |

|---|---|

| Size | L*W*H=950*920*1750MM |

| Shape | vertical |

| Weight | 220KG |

| Color | computer white |

| Power | AC220V 300W |

| PCBA board separates direction | X or Y one-way can be divided into boards, and the angle can be arbitrarily adjusted |

| Working air pressure/tube diameter | -20~50 ℃ |

| Minimum distance of parts from the cutting line | greater than or equal to 1.5mm |

| Maximum and minimum board length | 250*250mm 12*12mm |

| The maximum height of PCB components | PCBA front and back height limit sum less than 15MM |

| Misoperation protection | grating sensor, safety door cover, and software multi-protection. |

| Parameter settingAccording | go to the size of the V-slot touch screen, direct input |

| Memory module | can store 50 groups of programs |

| Splitting efficiency | 2s/knife |

| Blade angle | 10-30 degrees (selectable) |

| Replacement time | 15 minutes |

| Guide screw | on the silver guide force screw + three-axis moving platform |

| Maximum length and width of the assembly line | 650mm*250mm(can be customized) |

| Thickness of the board | 0.4-3.5mm |

| Power failure and gas cut-off function | yes |

| Work mode | manual release line, slitting, and feeding boards |

| Scope of application | Plug-in / Patch |

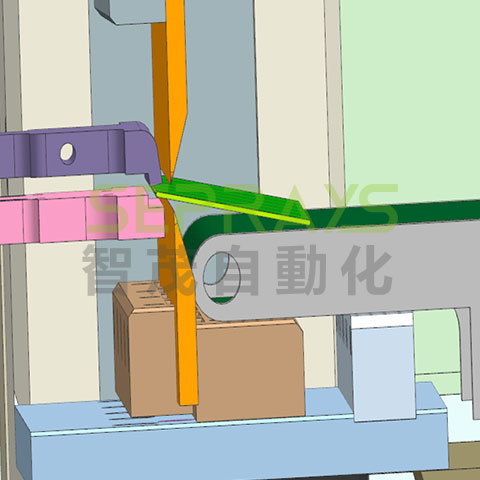

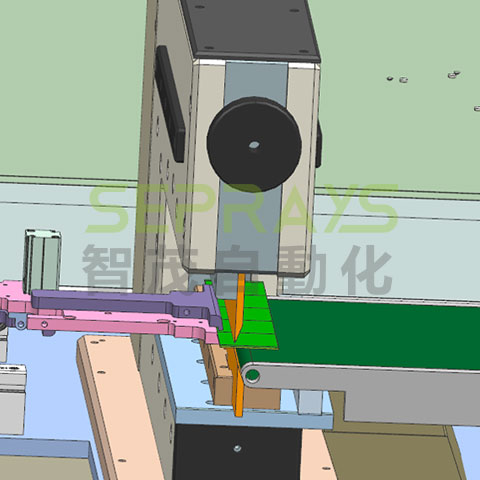

The ZM30-AP V-groove depaneling machine is a fully automated solution developed by SEPRAYS for efficient, precise, and safe V-groove PCB depaneling. From automatic feeding to cutting and discharging, this advanced system minimizes manual intervention and significantly boosts production efficiency.

Equipped with precision positioning technology, the ZM30-AP V-groove depaneling machine ensures exact alignment and cutting accuracy, protecting PCBA components and enhancing overall product quality. Its flexible material handling system—using suction cups and belt conveyors—accommodates a variety of PCB shapes and sizes with ease.

Integrated waste disposal keeps the workspace clean and streamlines production. Designed for continuous cycle operation, it’s ideal for high-volume manufacturing environments where speed and consistency are critical.

.png)

评价

目前还没有评价