Specifications

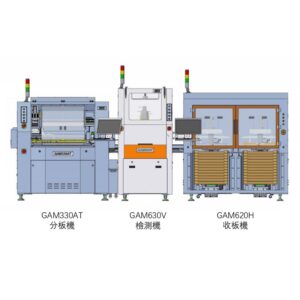

GAM310AT – Compact PCB Depaneling Specialist

Compact design: Compared to the standard model, the GAM310AT has a 45% shorter body length, making it more suitable for production environments with limited space.

Fast Cutting: Cycle time is less than 10 seconds, dramatically increasing the production tempo and meeting the needs of rapid production.

Size Adaptation: With a focus on small PCB board processing, the system achieves an effective cutting size of 200×180mm, ensuring both cutting accuracy and operational efficiency.

Front-end and back-end docking: Seamlessly integrated into the production line, the front end can be connected to the loading and unloading machine, and the back end of the docking pendulum machine, to realize a fully automated workflow.

GAM630V – The Guardian of Appearance Quality

Precision Inspection: Utilizes advanced vision technology to perform high-precision inspection of solder joints, component arrangement, surface defects, etc., on PCB boards.

Automatic Classification: Instantly distinguishes between qualified and unqualified products, ensures product quality control through OK/NG separation function, and reduces subsequent manual screening steps.

GAM620H – Intelligent Tray Setting Solution

Automated TRAY Handling: Automatically complete TRAY placement and replacement to enhance work efficiency and reduce labor burden.

Intelligent Recognition: Equipped with the function of picking up materials in front of empty and full TRAYs, through the intelligent recognition system, it can accurately judge and automatically process to ensure smooth operation.

Overall Advantage

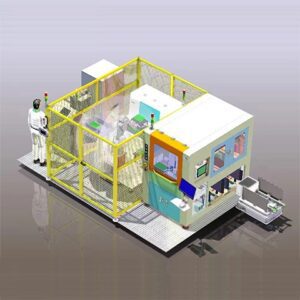

Flexible Configuration: GAM310AT, GAM630V, and GAM620H can be freely combined according to the actual production requirements, constituting a highly efficient small PCB board processing line.

Quality Assurance: From depaneling, inspection, to board placement, each step incorporates advanced technology and strict quality control to provide customers with stable and reliable production support.

Cost Optimization: Reduce labor costs through high automation, and at the same time, improve production efficiency and yield rate, which brings long-term cost savings and benefits to the enterprise.

Application Fields

Suitable for PCB post-processing in consumer electronics, communication equipment, medical electronics, automotive electronics, and other fields.

Cooperation Invitation

We invite you to experience this efficient and intelligent PCB post-processing solution. Whether you want to improve the performance of your existing production line or plan for a new production line, SEPRAYS will provide you with professional technical support and customized services. Contact us today to create a new chapter of intelligent manufacturing!

.png)

评价

目前还没有评价