PCB V-Cut Depaneling Machine: Practical Insights from High-Volume SMT Production

PCB V-Cut Depaneling Machine usage remains widespread in high-volume SMT production, particularly where board designs are standardized, and cost efficiency is critical. Despite the rise of routing and laser solutions, V-cut depaneling continues to play an important role in consumer electronics, power modules, and industrial products. This article shares practical insights from real SMT production […]

PCB Depaneling Machine Supplier: Router, Laser, or Blade Solutions Compared

PCB Depaneling Machine Supplier evaluation has become more complex as global SMT lines face increasing product diversity, thinner boards, and higher reliability expectations. Rather than asking which technology is “best,” engineers now compare router, laser, and blade solutions based on stress behavior, long-term stability, and total production cost. This article summarizes real-world insights shared across […]

Inline PCB Router Depaneling System in Germany: Precision and Traceability Requirements

Inline PCB Router Depaneling System in Germany is often discussed among SMT engineers because German manufacturing places exceptional emphasis on precision, documentation, and long-term reliability. In automotive, industrial control, and high-reliability electronics, depaneling is no longer a simple separation step—it is a controlled process that must meet strict quality and traceability expectations. This article summarizes […]

Automatic PCB Router Machine vs V-Cut Systems: What Global SMT Lines Prefer

The comparison between Automatic PCB Router Machines and V-Cut Systems is a topic frequently discussed among global SMT engineers, especially as PCB designs become thinner, denser, and more reliability-driven. While both technologies remain widely used, real production experience shows that the choice is rarely about speed alone—it is about long-term process stability, stress control, and […]

PCB Depaneling Machine Manufacturer: What Global SMT Lines Look for Beyond Price

PCB Depaneling Machine Manufacturer selection has become a strategic decision for global SMT lines, especially as electronics move toward higher density, thinner substrates, and longer product life cycles. While price is often the primary comparison point, engineers and production managers consistently report that long-term performance, process stability, and technical support are far more important than […]

PCB Router Depaneling Machine: What Engineers Learned About Accuracy and Stress Control

PCB Router Depaneling Machine selection has become a critical topic as PCB layouts grow denser and mechanical tolerances tighten. Across global SMT lines, engineers are no longer asking how fast a router can cut, but how consistently it maintains accuracy while minimizing mechanical stress over long production cycles. This article reflects shared lessons from real […]

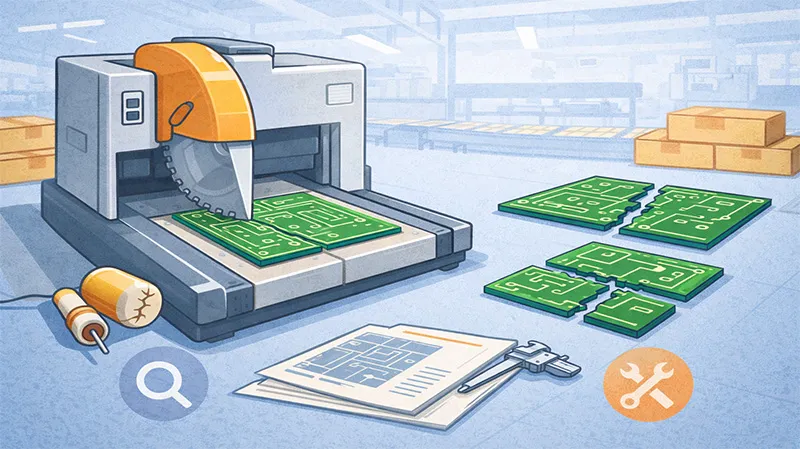

PCB Panel Cutting Machine: Lessons from Handling Thin and High-Density PCB Panels

PCB Panel Cutting Machine performance becomes increasingly critical as modern electronics move toward thinner substrates and higher component density. In recent years, SMT engineers across Europe, North America, and Asia have shared similar challenges: maintaining cut accuracy without introducing stress, protecting fine-pitch components, and controlling long-term operating costs. This article summarizes practical lessons learned from […]

PCB Depaneling Machine Recommendations: What Global SMT Lines Prefer in 2025

In 2025, global SMT lines—from Europe to Southeast Asia—continue to prioritize cutting stability, long-term durability, and predictable process quality when selecting a PCB depaneling machine. The decision is rarely made solely based on speed. Instead, factories focus on equipment robustness, maintenance intervals, integration capacity, and the ability to support increasingly complex PCB designs. This article […]

German SMT Lines: What Makes a High-Quality PCB Depaneling System?

German SMT production environments are known for their strict expectations on precision, durability, and process repeatability. When evaluating a PCB depaneling system, engineers focus not only on cutting performance but also on long-term stability, integration capability, and predictable cost of ownership. This article summarizes the practical criteria observed in German automotive, industrial control, and medical […]

PCB Depaneling Equipment: Router vs Laser vs V-Cut vs Saw Blade — What Works Best?

PCB Depaneling Equipment has evolved rapidly over the past decade as electronics manufacturers strive for higher-density boards, tighter tolerances, and a wider range of materials. Across Europe, North America, and Asia, factories have adopted different depaneling technologies based on volume demands, quality requirements, component sensitivity, and long-term equipment cost.This article shares real shop-floor observations, user […]

.png)