The PCB depaneling process plays a crucial role in modern electronics manufacturing. Every second saved, every micron of precision achieved, and every piece of dust eliminated adds up to a stronger, more reliable product line.

In today’s competitive market, achieving faster, cleaner, and more precise PCB depaneling is no longer optional — it’s essential. That’s where advanced automation systems like the SEPRAYS GAM 330AT In-Line Automatic PCB Router Machine redefine what’s possible.

⚙️ Why Traditional Depaneling Methods Fall Behind

Manual cutting or outdated semi-automatic systems often introduce vibration, dust, and human error.

Over time, these issues lead to component stress, poor edge quality, and inconsistent yield.

In contrast, smart inline depaneling solutions focus on stability, precision, and efficiency.

They combine advanced motion control, real-time vision alignment, and fully automated handling — eliminating the weak links of manual work.

🎯 CCD Vision Alignment: Precision at Every Cut

One of the biggest challenges in PCB depaneling is maintaining cutting accuracy as production speed increases.

The SEPRAYS GAM 330AT solves this with CCD vision alignment technology.

This system scans fiducial marks in real time and adjusts the cutting path automatically.

The result? Every board is cut with pinpoint precision, regardless of slight shifts in position.

Whether you’re working with small modules or complex multilayer boards, this feature ensures consistent perfection.

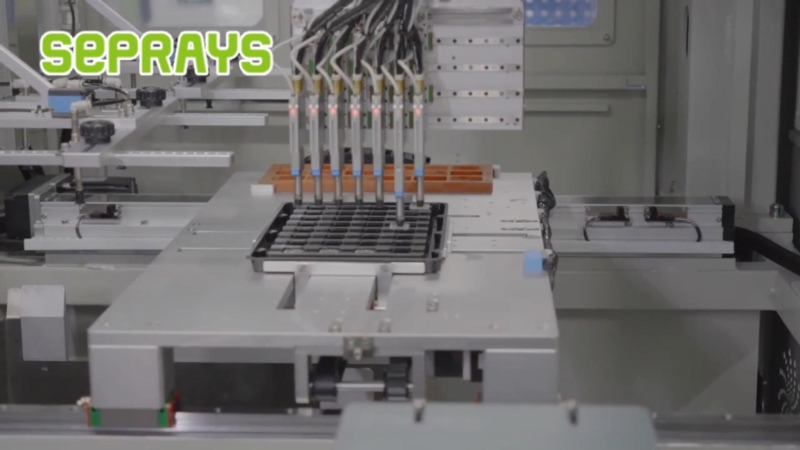

⚡ High-Speed Spindle with Auto Tool-Change

Speed matters — but not at the cost of reliability.

The high-speed spindle in the GAM 330AT delivers stable, low-stress cutting, even in continuous operation.

To minimize downtime, the system includes an auto tool-change function.

When a cutting bit wears down, the machine switches to a new one automatically, maintaining performance without operator intervention.

This keeps production lines running longer, with fewer interruptions and higher throughput.

🧹 Patented Flexible Cleaning Brush: Cleaner Cuts, Longer Life

Dust is one of the biggest enemies in PCB production.

It affects accuracy, damages spindles, and contaminates boards.

That’s why SEPRAYS developed a patented flexible cleaning brush system.

It automatically cleans the spindle and cutting area after each cycle, removing debris and extending spindle life.

This innovation ensures both cleanliness and mechanical longevity — two factors that directly impact long-term reliability.

🚀 Inline Automation: Continuous Flow, Zero Manual Handling

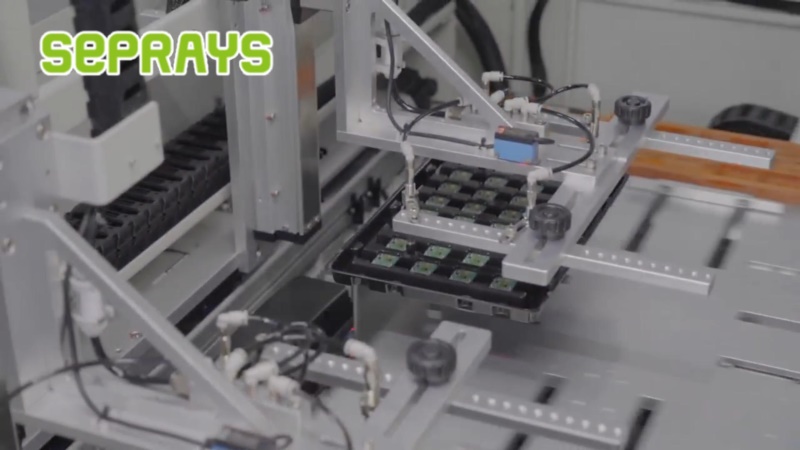

The SEPRAYS GAM 330AT is built for modern smart factories.

Its inline automation design allows continuous loading, cutting, and unloading — with no manual intervention required.

Boards move seamlessly through each stage, reducing cycle time and improving production efficiency.

This not only accelerates throughput but also reduces the risk of handling damage and human error.

For manufacturers targeting large-scale production — from consumer electronics to automotive systems — this smooth, automated workflow makes a major difference.

💡 Designed for Versatility and Stability

The PCB depaneling process varies across industries, but one constant remains: precision.

The GAM 330AT handles different board materials, thicknesses, and layouts with ease.

Its adaptive control system allows quick setup changes, making it ideal for diverse production requirements.

From fine-pitch communication boards to rigid-flex assemblies, this machine delivers the same standard of clean, accurate cuts.

🌿 Clean Production, Higher Yields

Cleaner cuts mean better quality and less waste.

With its integrated vacuum extraction and stress-free cutting process, the SEPRAYS GAM 330AT keeps both your PCBs and your workspace spotless.

Reduced stress ensures that sensitive components stay intact, minimizing failure rates and improving overall yield.

In a world that demands both sustainability and precision, this is a win-win.

🧩 Smart Automation Meets Cost Efficiency

Investing in an automatic PCB depaneling system is not just about speed — it’s about long-term savings.

Lower labor costs, reduced scrap rates, and minimized maintenance translate into measurable ROI.

The SEPRAYS GAM 330AT gives manufacturers a scalable path to Industry 4.0 readiness, blending precision engineering with intelligent automation.

🌟 Why Choose Seprays Group?

At Seprays Group, we design more than machines — we engineer confidence.

From PCB depaneling to fully automated production systems, every solution is crafted with precision, care, and innovation.

Our equipment is trusted by global manufacturers for its stability, performance, and intelligent design.

We’re dedicated to helping you achieve cleaner cuts, faster cycles, and more consistent results — every single time.

If you’re ready to transform your PCB manufacturing line, we’re here to help.

📞 WhatsApp: +86 189 2926 6433

📧 Email: sales@seprays.com

.png)