Router bit lifespan in PCB depaneling machines plays a crucial role in ensuring consistent cut quality, maintaining production efficiency, and reducing operating costs. When bits wear out too fast, manufacturers face increased downtime, scrap rates, and replacement expenses — all of which directly impact profit margins.

This article explores the real causes of premature tool wear, the engineering principles behind router bit longevity, and practical strategies used by leading PCB manufacturers to extend tool life.

⚙️ Understanding Router Bit Wear

In PCB depaneling, router bits are exposed to high-speed rotation (up to 100,000 RPM) and continuous cutting through materials like FR4, aluminum, or polyimide. Over time, this leads to:

- Edge dulling due to heat and friction.

- Material adhesion (resin buildup) on the cutting flutes.

- Mechanical fatigue from vibration or excessive feed rates.

The goal is not just to use a harder bit, but to manage the interaction between spindle speed, cutting path, and material type to minimize wear.

💡 Key Factors Affecting Router Bit Lifespan

- Cutting Speed & Feed Rate

A common mistake is running the spindle too fast. While high RPM ensures smoother cuts, it also generate more heat. Balancing spindle speed (60,000–80,000 RPM) with the correct feed rate prevents bit overheating and premature dulling. - Dust Collection Efficiency

Fine PCB dust can accumulate around the cutting area, increasing friction and damaging both the router bit and the spindle bearings. Machines with high-efficiency vacuum extraction systems drastically reduce this issue. - Bit Coating & Geometry

Coatings like TiAlN or diamond-like carbon (DLC) help dissipate heat and resist resin adhesion. Similarly, choosing the right flute design — up-cut vs. down-cut — improves chip evacuation and reduces cutting load. - Material Hardness

FR4 boards with high glass fiber content wear bits faster than softer materials. Adjusting cutting depth or using multi-step routing can extend bit life when working with tougher boards. - Tool Change Management

Many modern SEPRAYS router depaneling machines use automatic tool change systems that replace worn bits at pre-set intervals. This not only improves consistency but also avoids costly unplanned downtime.

🔍 Cost Analysis: The True Impact of Router Bit Lifespan

Let’s look at an example from a European electronics assembly plant:

- Each router bit costs around $30–$50.

- A worn bit typically lasts for 500–800 boards, depending on the material.

- By optimizing cutting parameters and implementing real-time bit monitoring, the factory increased average lifespan by 35%.

This translated to a 12% reduction in total cutting costs per year, including bit purchases, labor, and rework.

🧩 Practical Tips to Extend Router Bit Life

✅ Monitor cutting sound and vibration: Sudden changes indicate dullness or imbalance.

✅ Use bit wear sensors: Modern PCB routers can detect resistance increases and prompt tool replacement.

✅ Clean bits regularly: Remove resin buildup after each shift to maintain sharpness.

✅ Optimize routing paths: Shorter, more efficient paths reduce travel time and wear.

✅ Implement temperature control: Cooling systems or air blowers prevent thermal expansion damage.

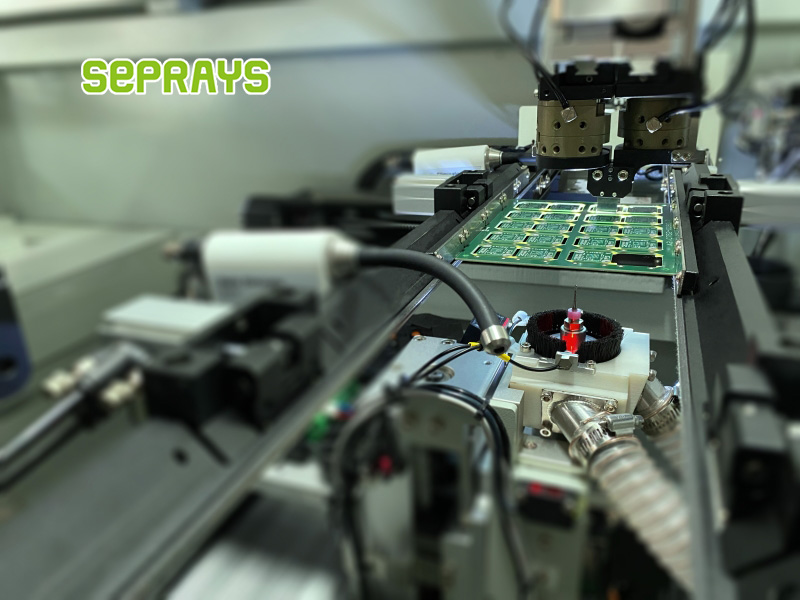

🏭 Case Study: Smart Optimization with SEPRAYS Router Machine

A Southeast Asian EMS manufacturer struggled with frequent tool replacements — every 600 boards on average. After switching to a SEPRAYS high-speed router equipped with German spindle technology and intelligent feed-rate optimization, tool lifespan increased to 950 boards per bit.

The machine automatically adjusted speed based on board density, maintaining a constant cutting load. Over six months, maintenance costs dropped by 28%, and output consistency improved noticeably.

🧠 Expert Insight: Balancing Quality and Efficiency

Router bit lifespan should not be viewed in isolation. Longer life means less downtime, but pushing bits beyond their limit risks quality issues such as burrs or delamination. The goal is to find the sweet spot between tool cost and cut integrity — where every cut remains precise, clean, and burr-free.

🌍 Why Choose Seprays Group?

With over 30 years of expertise in PCB/FPC depaneling, Seprays Group provides comprehensive solutions that integrate router, laser, V-cut, and punching systems — all designed for precision, stability, and cost efficiency.

Our equipment features:

- High-speed German spindles up to 100,000 RPM.

- Automatic bit change and wear detection.

- Intelligent path optimization for consistent quality.

- Full automation with tray handling and robotic integration.

If you’re seeking to extend router bit lifespan while maintaining top-tier cutting quality, contact Seprays Group today — let’s engineer smarter, faster, and more reliable PCB depaneling together.

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)