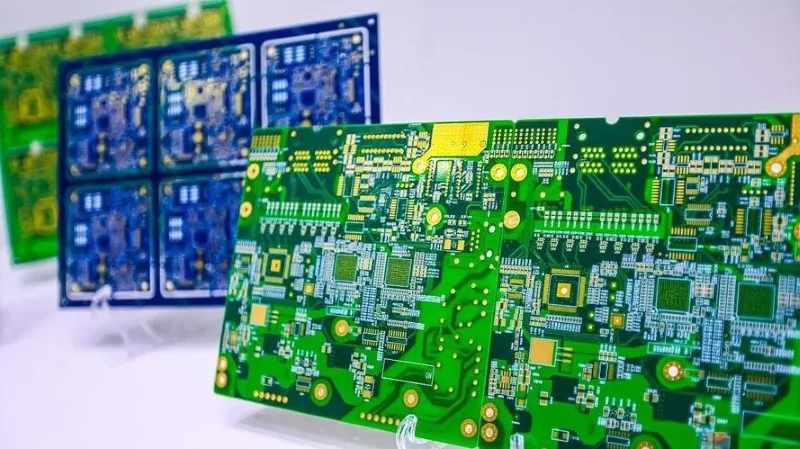

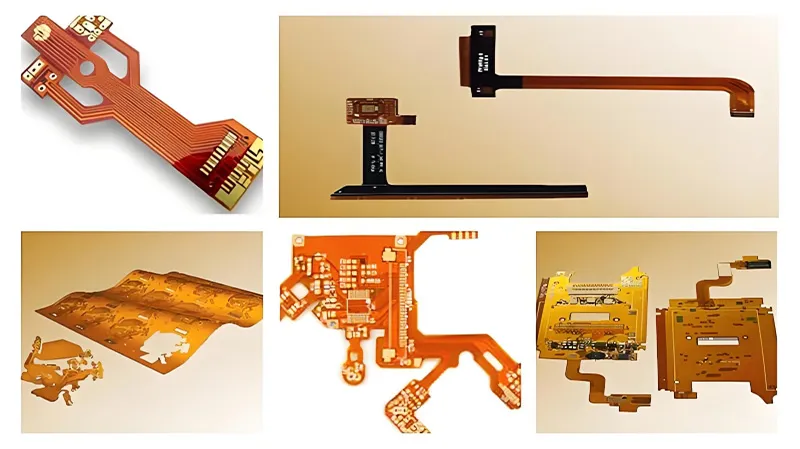

FPC Depaneling Solutions for Industrial Electronics are gaining attention as flexible circuits become more common in control systems, power modules, sensors, and human–machine interfaces. Compared with rigid PCBs, FPCs introduce unique challenges during depaneling due to their thin substrates, mixed materials, and sensitivity to mechanical stress. This article shares field-tested insights from industrial SMT environments focused on yield stability rather than short-term throughput.

🧠 Why FPC Depaneling Is a Yield-Sensitive Process

Industrial electronics often operate in harsh conditions, making early-stage process stability critical. Engineers report that FPC-related yield loss frequently originates not in assembly, but during panel separation.

Common challenges include:

- Deformation or stretching during cutting

- Micro-tears at connection points

- Stress transfer to bonded stiffeners

- Inconsistent edge quality affecting later assembly

Unlike rigid boards, FPC defects may not be immediately visible, increasing the importance of conservative depaneling strategies.

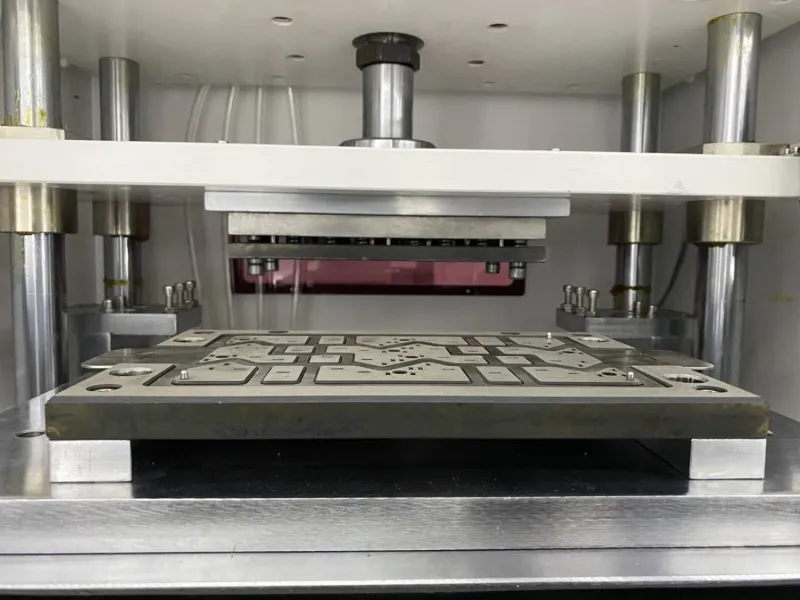

⚙️ Mechanical Depaneling: Control and Support Matter

Mechanical depaneling methods are still widely used for FPCs when supported correctly.

Field experience highlights:

- Proper fixture design is essential to prevent material movement

- Cutting speed must be reduced compared with rigid PCB processes

- Tool sharpness directly affects edge integrity

In one industrial control project, adding full-surface vacuum support reduced FPC deformation-related scrap by over 25%, without changing the depaneling technology itself.

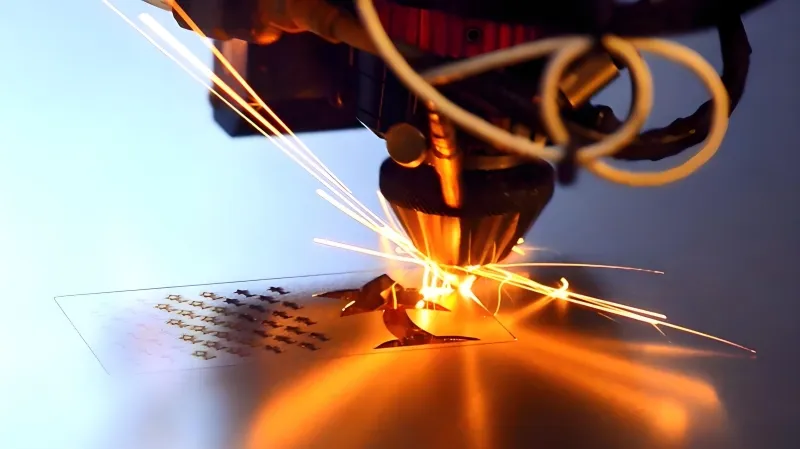

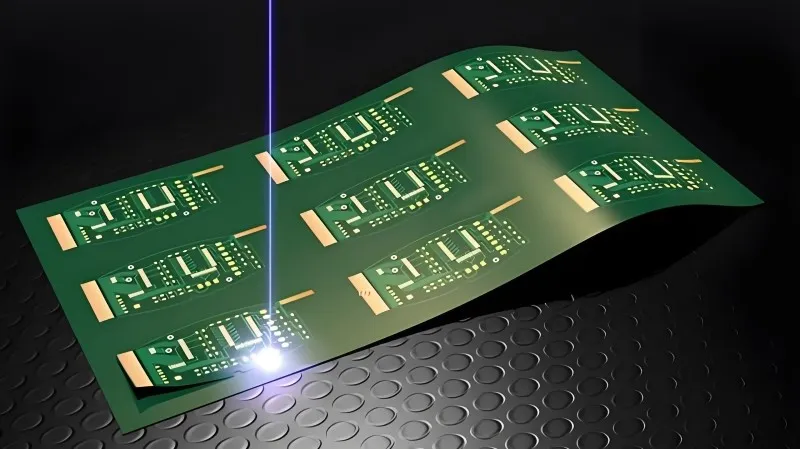

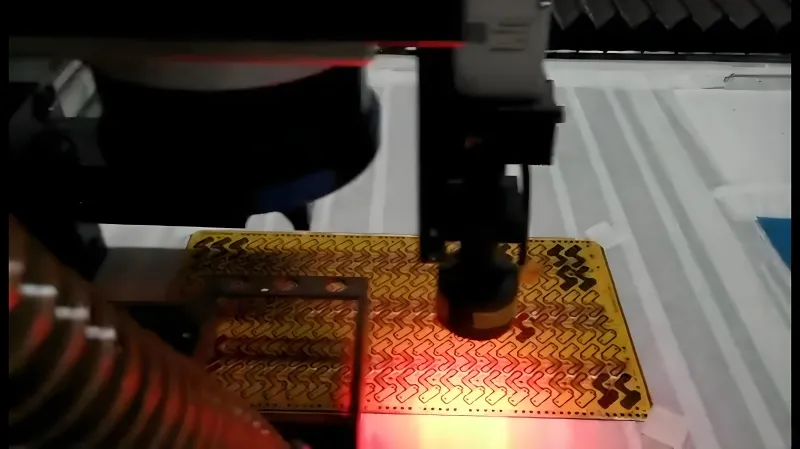

🔦 레이저 구분: Precision with Process Discipline

Laser depaneling is often discussed for FPC applications due to its non-contact nature.

Reported benefits:

- Minimal mechanical stress

- High repeatability for complex outlines

- Clean separation without physical force

However, engineers caution that process discipline is critical. Incorrect laser parameters can cause localized heat effects, impacting polyimide layers or adhesive bonds. As a result, laser depaneling is typically reserved for high-value or highly sensitive FPC designs.

📉 Cost Analysis: Yield Stability vs. Equipment Price

From an industrial electronics perspective, cost discussions focus on yield stability rather than machine price alone.

Hidden cost factors include:

- Scrap from early-stage FPC damage

- Rework caused by handling deformation

- Delays from manual inspection and sorting

Several EMS providers report that investing in more controlled depaneling processes reduced overall cost per unit, even when equipment investment increased.

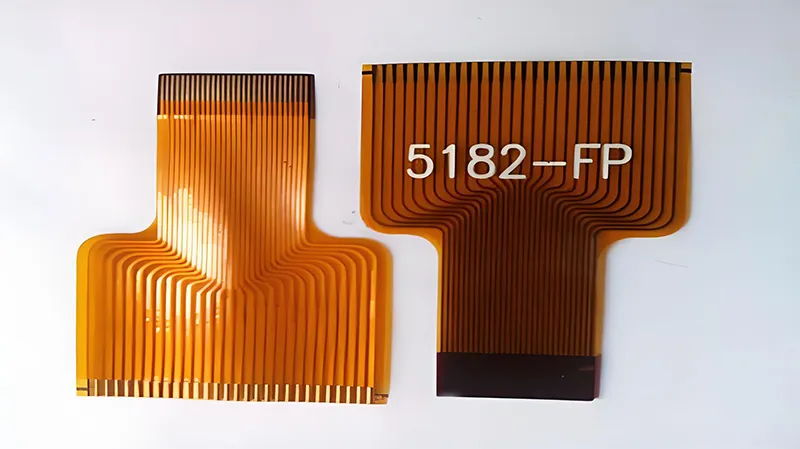

🏭 Case Insight: Industrial Sensor Module Production

An industrial sensor manufacturer experienced inconsistent yields due to FPC cracking near connector areas. After redesigning the depaneling fixture and adjusting cutting parameters, the yield stabilized across multiple production batches. No changes were made to materials or assembly processes—highlighting the impact of depaneling optimization alone.

🛠️ Practical Strategies for Stable FPC Depaneling

Engineers working with industrial FPCs commonly recommend:

- Treat depaneling as part of the FPC design review

- Prioritize material support over cutting speed

- Validate edge quality under bending conditions

- Monitor process drift over long production cycles

These steps help align depaneling with industrial durability expectations.

💬 Why Choose Seprays Group?

Seprays Group provides depaneling solutions developed with a focus on industrial-quality standards, durability, and yield stability. Our experience with FPC depaneling supports manufacturers in selecting and optimizing processes that perform reliably in real production environments.

If you would like to discuss FPC depaneling challenges or evaluate solutions for your industrial electronics projects, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)