PCB depaneling plays a crucial role in electronics manufacturing — it’s the final step between assembly and product readiness. Yet for many factories, it remains a bottleneck. Long cycle times, uneven cutting quality, and costly manual handling all limit productivity.

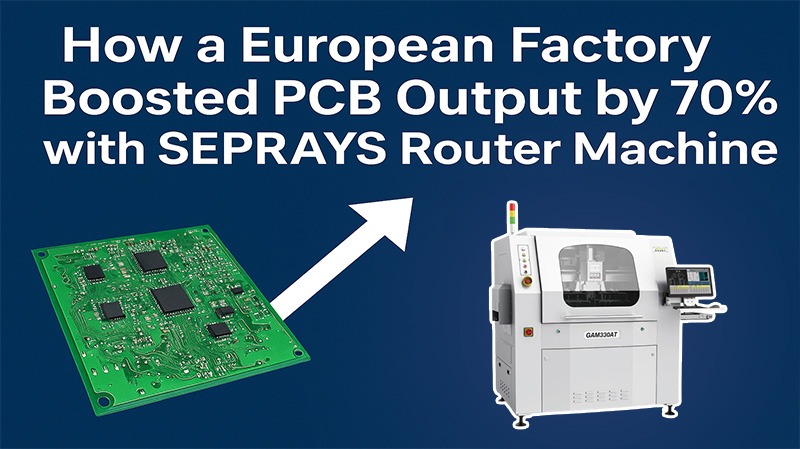

A European electronics manufacturer recently faced these exact challenges. By adopting the SEPRAYS Router Machine, the company transformed its production line, achieving a 70% increase in PCB output — all while improving yield and reducing operating costs.

🔍 The Pain Points: Manual and Semi-Automatic Limitations

Before upgrading, the factory relied on semi-automatic depaneling with operator-assisted routing. While sufficient for small batches, it caused several pain points when scaling up:

- High labor dependency: Each shift required multiple skilled operators.

- Inconsistent quality: Manual adjustments led to irregular cut depth and edge burrs.

- Frequent downtime: Tool changes and fixture alignment disrupted workflow.

- Limited throughput: One depaneling cycle took up to 45 seconds per PCB set.

As production volume grew — especially for automotive and communication boards — these inefficiencies became unsustainable. The company needed a scalable, high-speed, low-stress depaneling solution.

⚡ The Solution: SEPRAYS Router Machine Integration

After detailed process analysis, SEPRAYS recommended the GAM330AT In-Line PCB Router Machine, designed for automated depaneling in SMT production lines.

Key features that addressed the factory’s challenges included:

- CCD vision alignment for precise positioning and cutting accuracy.

- Automatic loading/unloading that eliminated manual handling between steps.

- High-speed spindle motor ensures smooth and burr-free cuts.

- Smart tool management that automatically changed bits and monitored wear.

- MES connectivity for real-time production data and quality tracking.

Integration was completed in under two weeks, without disrupting existing SMT processes.

💡 The Results: 70% Output Growth and Cost Optimization

After one quarter of operation, the results were measurable and impressive:

| Performance Metric | Before (Manual/Semi-Auto) | After (SEPRAYS Router) |

|---|---|---|

| PCB Output/Day | 3,000 units | 5,100 units (+70%) |

| Defect Rate | 3.8% | 0.6% |

| Labor Requirement | 4 operators | 1 operator |

| Average Cycle Time | 45 sec | 18 sec |

| Tool Change Downtime | 40 min/day | 10 min/day |

The SEPRAYS Router Machine not only increased capacity but also improved consistency, accuracy, and machine uptime. The cost-per-board dropped significantly, while product quality met stricter customer standards.

🏭 Case Highlights: From Bottleneck to Benchmark

The factory’s production manager shared valuable insights from the upgrade:

“Our previous depaneling method was a constant source of delay. After integrating SEPRAYS’ router machine, the line runs smoother than ever. The automated handling system alone saved us hours every day.”

By leveraging automation, the company turned its biggest bottleneck into a benchmark for process efficiency, inspiring its other European facilities to adopt similar solutions.

💬 Discussion: What Does This Mean for the Industry?

This case highlights a growing trend in Europe’s electronics manufacturing sector — precision automation replacing manual or semi-automatic processes.

Router depaneling systems like SEPRAYS are no longer just about speed; they’re about consistency, intelligence, and flexibility. Factories now demand machines that integrate seamlessly with Industry 4.0 ecosystems, where data-driven decision-making and predictive maintenance redefine productivity.

As global competition intensifies, investing in such technology is less about replacing labor and more about enabling people to focus on higher-value engineering and optimization work.

What’s your experience? Has your production line already adopted smart depaneling automation, or are manual processes still creating hidden costs?

💰 Cost and ROI Insights

While the initial investment in a router machine may appear higher than manual systems, the return on investment (ROI) typically occurs within 6–12 months. The key cost savings come from:

- Reduced manpower and overtime expenses

- Fewer defective boards and material waste

- Shorter cycle times and improved yield

- Lower maintenance costs due to automatic tool calibration

Over time, these factors lead to sustainable cost reduction and stronger operational resilience.

✅ Why Choose Seprays Group?

Seprays Group is a global leader in PCB depaneling technology, specializing in router, laser, V-cut, and punching systems — all designed for precision, reliability, and intelligent automation.

With over 32 years of engineering expertise, Seprays provides complete solutions from R&D to after-sales support, ensuring every customer achieves optimal productivity with minimal stress on their boards.

If you’re exploring ways to increase PCB output, reduce labor dependency, or integrate smart automation,

Contact Seprays Group today.

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

Our team will help you identify the best solution tailored to your production goals.

.png)