Dual-platform milling cutter depaneling machine efficiency is a topic that frequently arises when SMT lines encounter throughput bottlenecks, but hesitate to add headcount or floor space. On paper, the answer seems simple: dual platforms mean higher output. In reality, the efficiency gain depends on workflow design, product mix, and how “productive time” is defined on the shop floor.

This article shares practical observations from EMS and OEM factories, focusing on industrial quality, durability, and realistic return on investment—rather than idealized cycle-time calculations.

🔍 Understanding the Real Bottleneck in Single-Platform Routing

In many single-platform systems, the limiting factor is not cutting speed, but non-cutting time, such as:

- Loading and unloading panels

- Manual alignment and clamping

- Operator confirmation between cycles

Field data shows that the spindle may be cutting only 60–70% of total machine time. The rest is idle by necessity.

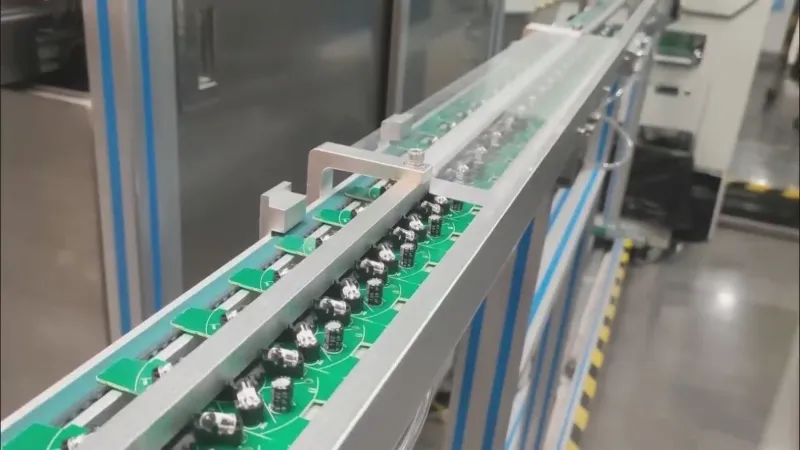

⚙️ What a Dual-Platform System Changes

A dual-platform design separates cutting and handling into parallel actions:

- One platform is routed while the other is being loaded or unloaded

- The spindle remains active for a higher percentage ofthe total time

- Operator interaction is smoother and less rushed

In stable production scenarios, this structural change alone often increases effective utilization.

📊 Efficiency Gains: What Production Lines Actually See

Across multiple SMT environments, typical improvements reported include:

- 30–50% higher throughput compared to single-platform machines

- Reduced queue time before depaneling

- More predictable takt time during multi-shift operation

The exact gain depends on panel size, routing complexity, and operator skill, but few lines see less than a one-third improvement.

🧠 User Pain Points Addressed by Dual Platforms

Engineers often choose dual platforms not just for speed, but to solve persistent operational issues:

- Operators feel pressured during manual loading

- Inconsistent cycle times between shifts

- Difficulty keeping up with upstream SMT output

By decoupling handling from cutting, process stability improves along with speed.

💰 Cost Analysis: Is the Upgrade Justified?

From a cost perspective, dual-platform systems typically involve a higher initial investment. However:

- Output per square meter of floor space increases

- One operator can support a higher volume without overtime

- Lower spindle idle time improves equipment ROI

Several EMS factories reported reaching break-even within 12–18 months after switching, without changing staffing levels.

🏭 Case Insight: Industrial Power Electronics Line

A European industrial electronics manufacturer replaced a single-platform router with a dual-platform system to support thicker, mixed-panel designs. The result was a 42% increase in daily output and noticeably smoother shift transitions, especially during night operations where operator efficiency varied more.

🛠️ Practical Considerations Before Choosing Dual Platforms

Engineers recommend evaluating:

- Product mix stability (high-mix lines may gain less)

- Available operator training

- Integration with upstream and downstream equipment

A dual-platform system delivers the best value when depaneling is a recurring bottleneck, not an occasional step.

🌍 Alignment with Global SMT Manufacturing Trends

As SMT lines move toward higher automation and labor efficiency, keeping spindles cutting instead of waiting aligns with global production expectations—especially in regions with rising labor costs and stricter delivery schedules.

💬 Why Choose Seprays Group?

Seprays Group develops industrial-grade milling cutter depaneling machines, including dual-platform solutions designed for long-term reliability, stable accuracy, and real-world efficiency gains. Our focus is on helping production lines improve throughput without sacrificing quality or durability.

If you would like to determine whether a dual-platform system is suitable for your SMT line, please do not hesitate to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)