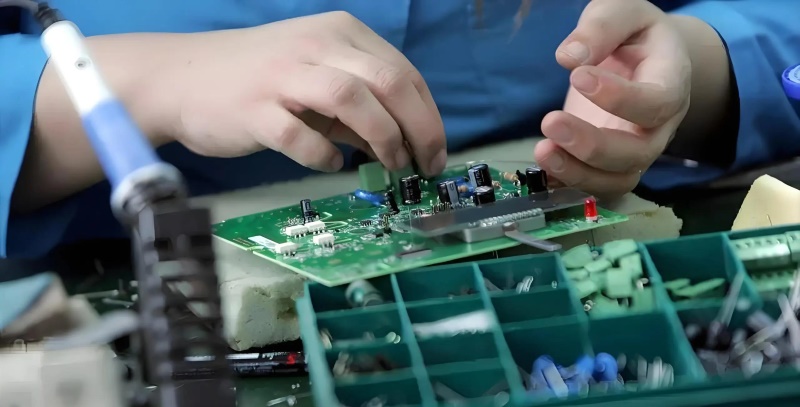

The cutting depaneling machine has become a crucial part of modern electronics manufacturing. Yet, some factories still rely on manual PCB cutting — a process that seems simple, but often hides high costs, low precision, and unnecessary risks. Let’s discuss why transitioning to automated depaneling is not just an upgrade, but a necessity for today’s competitive industry.

⚙️ The Pain Points of Manual PCB Cutting

Manual cutting may look flexible and cost-saving at first glance. However, it often introduces hidden issues:

- Inconsistent quality – Human operation leads to variations in cutting accuracy.

- High stress on boards – Manual pressure can cause microcracks or solder joint damage.

- Operator fatigue – Long hours of repetitive motion reduce efficiency and increase error rates.

- Limited throughput – Each cut requires time and precision, making scaling difficult.

These pain points not only affect product quality but also delay your overall production cycle.

💸 The Real Cost of “Cheap” Manual Operations

It’s easy to assume that manual cutting is cheaper because it doesn’t require expensive machinery. But when you look deeper, the numbers tell another story.

| Cost Factor | Manual Cutting | Cutting Depaneling Machine |

|---|---|---|

| Labor | High | Low (1 operator can handle multiple units) |

| Scrap Rate | High due to inconsistency | Minimal with precision control |

| Maintenance | Low upfront, but high rework cost | Predictable and efficient |

| Productivity | Limited | Continuous and scalable |

Over time, the cutting depaneling machine actually reduces total operational costs, even if the initial investment seems higher.

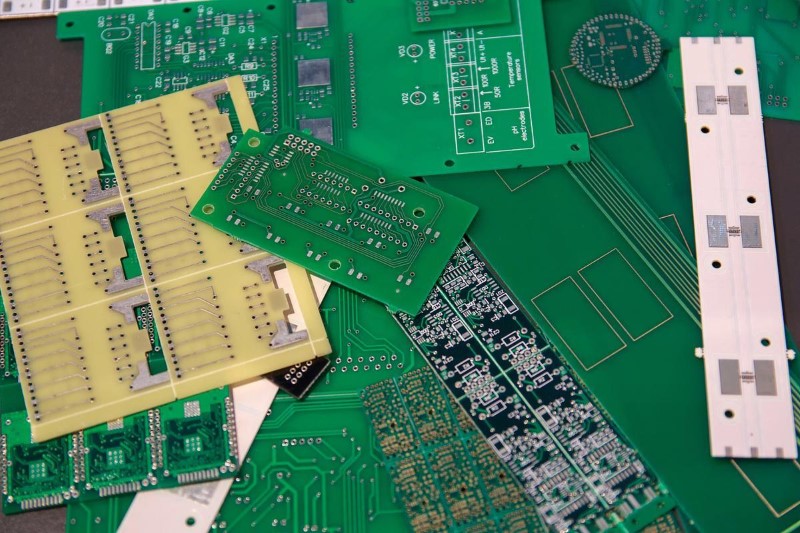

📐 Precision: The Heart of Modern Electronics

Today’s PCB designs are denser and more complex. Components are smaller, traces are tighter, and tolerances are narrower. Manual cutting simply cannot guarantee the precision required by industries like automotive, medical, or telecommunications.

A cutting depaneling machine ensures:

- Low-stress cutting with no component damage.

- Repeatable precision across thousands of panels.

- Clean, burr-free edges for improved assembly fit.

This precision directly translates into reliability, less rework, and longer product life.

🚀 A Real-World Case: From Manual to Automated

A mid-size electronics factory in Malaysia once relied on manual V-cut separation for LED driver boards. Each operator could only process around 200 boards per hour, and rejects were rising due to cracked solder joints.

After adopting an automatic cutting and depaneling machine, the results were clear:

- Output increased to over 800 boards per hour.

- The rejection rate dropped by 75%.

- Operators were reassigned to inspection and logistics, maximizing human efficiency.

Automation didn’t replace workers — it empowered them to focus on higher-value tasks.

🌍 Beyond Efficiency: Sustainability and Workplace Safety

Manual cutting often produces dust and debris, which can affect both the product and the worker. Automated depaneling systems typically include:

- Integrated dust extraction to maintain a clean workspace.

- ESD-safe design to protect sensitive circuits.

- Noise reduction for improved working conditions.

In the long run, this contributes to a more sustainable and worker-friendly environment.

💡 When Is It Time to Upgrade?

You might ask — “When should we switch?” Here are clear signs that your factory is ready for automation:

- Your throughput can’t meet demand.

- You notice frequent PCB cracking or solder joint issues.

- Labor costs are rising.

- Product quality is inconsistent.

If you recognize any of these, it’s time to evaluate a cutting depaneling machine.

🧠 Discussion: Balancing Cost, Quality, and Automation

Automation isn’t just about cutting faster — it’s about building smarter production systems.

When manufacturers adopt intelligent depaneling, they’re investing in:

- Consistent product quality

- Predictable delivery schedules

- Reduced manufacturing waste

These are the true advantages that separate reactive operations from world-class production lines.

⭐ Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

We combine advanced engineering with reliable service support, helping manufacturers achieve higher yields and smoother production.

For more information, please contact us:

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)