는 무엇입의 작동 원리는 레이저 구분?

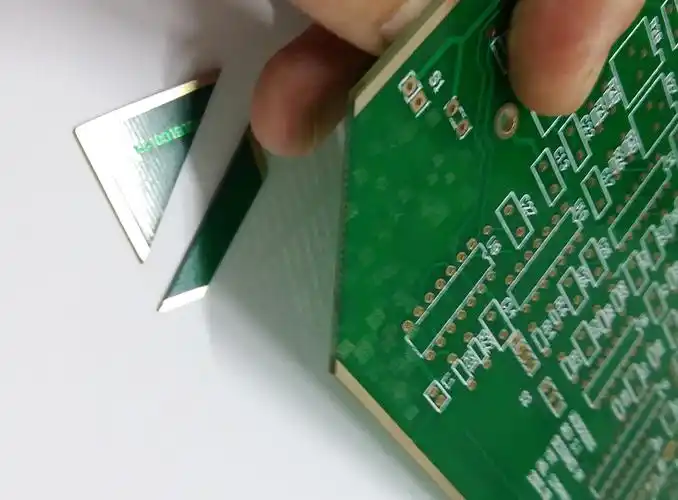

의 작동 원리는 레이저 구분 사용하는 것은 높은 에너지 레이저 광속을 정확하게 잘라를 연결하는 탭이나의 라우팅 채널의 PCB(인쇄 회로 기판)판,분리하는 개인 보드지 않고 기계적인 접촉입니다. 레이저 소스와 같은 CO2 외선 레이저를 생성합된 빔에 감독 PCB 소재를 통해 광학 시스템입니다.

When the laser interacts with the material, its energy is absorbed, causing localized heating and vaporization (ablation) along the programmed cutting path. This process is controlled by software that guides the laser head with high precision, enabling the creation of complex shapes and fine details to be cut cleanly. Since laser depaneling is a non-contact method, it eliminates mechanical stress, reduces the risk of damage to sensitive components, and produces minimal debris, making it ideal for high-density and delicate PCB designs.

어떤 종류의 레이저에서 사용되는 레이저 구분?

CO2Lasers:

- Best for cutting non-metal materials, such as FR-4 (a common PCB material).

- Fast and cost-effective, but can’t cut metals well.

UV 레이저:

- Great for high-precision cutting, especially for flexible PCBs or materials with copper.

- Very accurate with minimal heat damage, but slower and more expensive.

녹색 레이저:

- Used for specific materials like flexible circuits.

- Offers good precision but is less common and more costly.

광섬유 레이저:

- Used for cutting metal-based PCBs.

- Efficient for metals but not suitable for non-metal materials.

펨토초 레이저:

- Ultra-high precision with almost no heat damage.

- Ideal for delicate materials, but very expensive and slow.

피코 레이저:

- Similar to femtosecond lasers but slightly less precise.

- Still high-cost and used for advanced applications.

엑시머 레이저:

- Used for very precise cutting of special materials.

- High resolution but expensive and complex to maintain.

의 차이점은 무엇 CO2 레이저와 자외에서 레이저 구분 응용 프로그램은 무엇입니까?

의 차이점은 무엇 레이저 구분하고 전통적인 기계 구분?

Seprays'레이저을 가진 솔루션

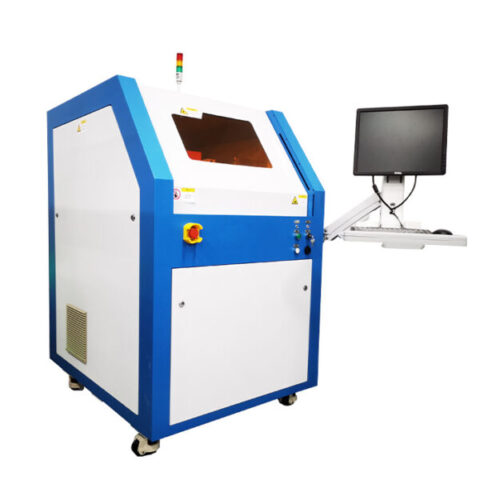

ZAM310/PCB FPC 레이저 절단

SEPRAYS’ZAM310 PCB/FPC Laser cutting machines ensure that no stress is imparted to nearby components, even when the cutting path is very close to them. To further minimize thermal impact, lasers are carefully selected based on thermal requirements, and their processing parameters are precisely matched to optimize performance.

ZAM320/PCB FPC 레이저 절단 기계

SEPRAYS’ZAM320 PCB/FPC Laser Cutting Machine has a compact design and can save factory space. A variety of nanosecond, picosecond UV, and green lasers are available to meet various processing needs.

결론

레이저 구분 is a major improvement in PCB manufacturing, offering precise, clean cuts without damaging sensitive components. By understanding how it works and the types of lasers used, manufacturers can choose the best method for their needs. As electronics continue to get smaller and more complex, laser depaneling will become even more important. With its ability to cut delicate designs without stress or debris, laser depaneling is shaping the future of electronics production.

.png)