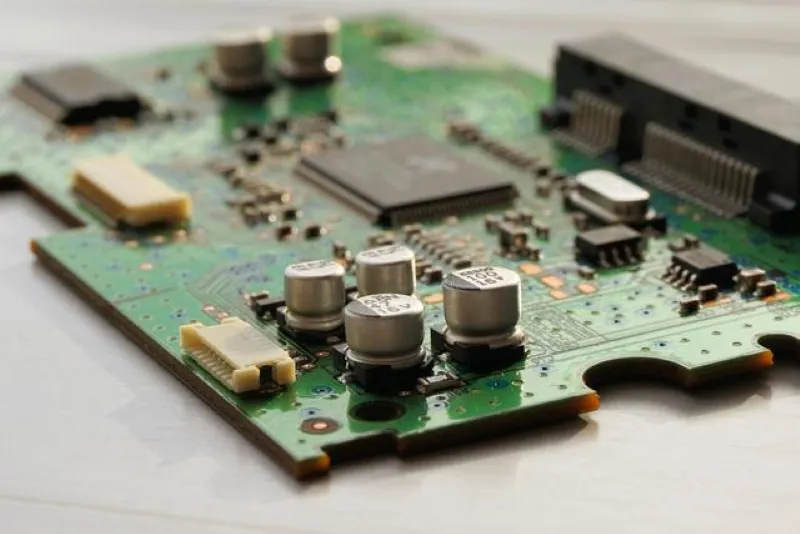

Low-Stress Depaneling Solutions have become a priority as PCBAs grow thinner, denser, and more functionally integrated. In applications such as automotive electronics, industrial controls, and medical devices, depaneling is no longer viewed as a simple mechanical step—it is a process that can directly influence long-term reliability. This article shares practical approaches that engineers report actually working on fragile and high-density PCBAs.

⚙️ Why Fragile PCBAs React Differently to Depaneling

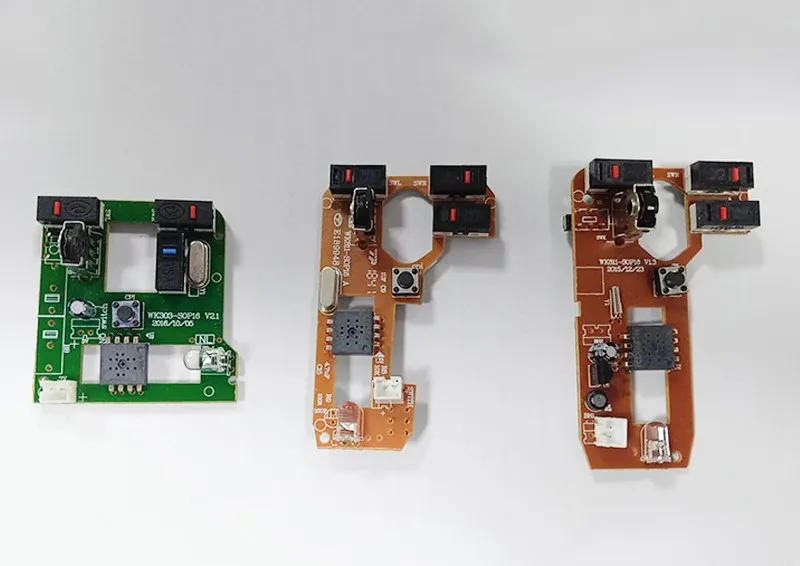

Dense PCBAs often combine fine-pitch components, edge-mounted connectors, and multi-layer stackups. During depaneling, even moderate mechanical force can propagate stress into sensitive areas.

Common pain points reported by SMT engineers include:

- Micro-cracks in ceramic capacitors near board edges

- Solder joint fatigue was revealed only during reliability testing

- Panel flex transferring force across densely populated zones

Because these issues rarely appear during visual inspection, depaneling-related stress is increasingly treated as a preventive quality risk.

🧩 Routing with Stability in Mind

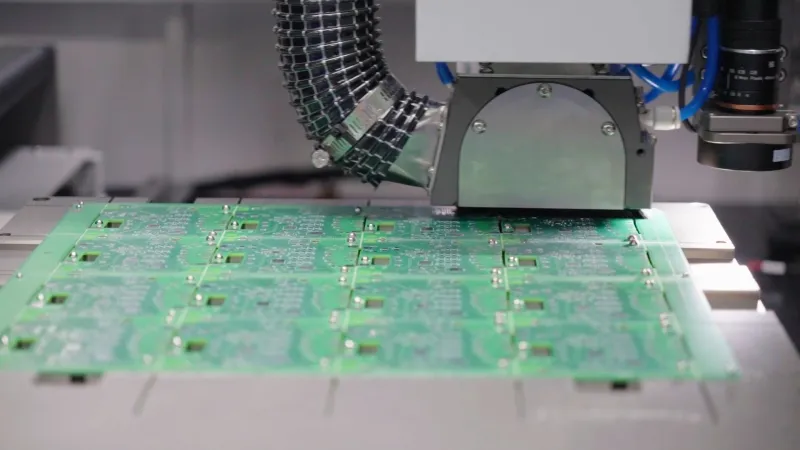

Router depaneling remains widely used for dense layouts due to its flexibility and adaptability. However, field experience shows that stress control depends less on routing itself and more on how it is implemented.

Effective practices include:

- Matching spindle speed and feed rate to PCB thickness and copper density

- Using high-rigidity spindles to minimize vibration

- Applying full-surface vacuum or adaptive fixtures to reduce panel flex

Several industrial electronics lines report noticeable yield improvement after upgrading fixtures rather than changing machines.

🪚 V-Cut Depaneling: When Simplicity Needs Discipline

V-cut depaneling is still common in high-volume environments, but fragile PCBAs demand tighter control.

Engineers emphasize:

- Consistent scoring depth across the panel

- Controlled separation speed to avoid sudden stress release

- Adequate design clearance between components and score lines

When these conditions are met, V-cut can remain viable even for moderately dense assemblies.

🔦 레이저 구분 for Stress-Sensitive Boards

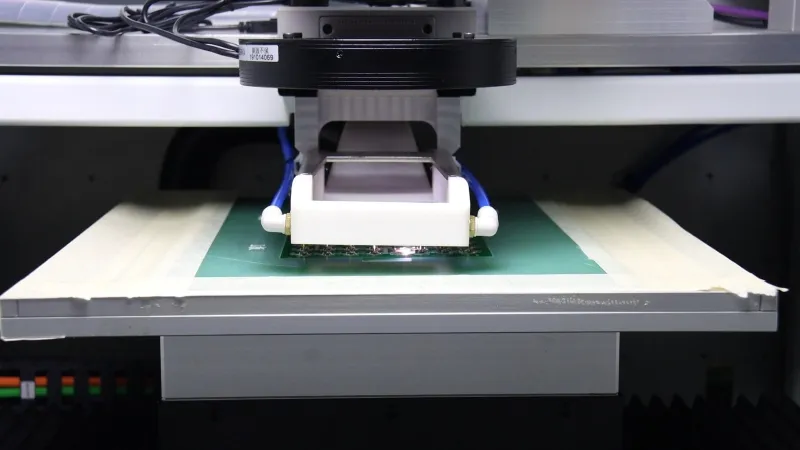

Laser depaneling attracts attention for fragile PCBAs because it removes mechanical contact entirely.

Observed advantages:

- Minimal mechanical stress

- High repeatability for complex outlines

- Clean edges suitable for dense component placement

That said, production teams caution that laser parameters must be carefully managed to avoid thermal effects on substrates and adhesives. As a result, laser solutions are typically applied selectively rather than universally.

📉 Cost Perspective: Stress Reduction vs. Downstream Loss

From a cost standpoint, stress reduction is often justified not by equipment price, but by what it prevents.

Hidden costs linked to depaneling stress include:

- Rework discovered during functional or aging tests

- Scrap caused by latent defects

- Extended failure analysis and customer communication

Many manufacturers find that investing in low-stress depaneling reduces total cost per board over time.

🏭 Case Insight: Dense Industrial Control PCBA

A control system manufacturer experienced intermittent failures during vibration testing. Root-cause analysis linked the issue to panel flex during depaneling. After implementing enhanced panel support and revised routing paths, failures dropped significantly without changes to PCB layout or components—highlighting depaneling’s influence on reliability.

🛠️ Practical Engineering Takeaways

Based on shared production experience:

- Treat depaneling as part of the reliability strategy

- Prioritize stability and support over cutting speed

- Validate depaneling results through stress testing, not only AOI

- Choose processes that remain consistent over long production cycles

These principles align depaneling decisions with industrial-quality expectations.

💬 Why Choose Seprays Group?

Seprays Group develops depaneling solutions with a strong focus on industrial quality, durability, and low-stress performance for fragile and dense PCBAs. Our experience across routing, V-cut, and laser technologies helps manufacturers match depaneling methods to real production conditions.

If you would like to discuss low-stress depaneling strategies or evaluate suitable solutions for your application, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)