PCB Depaneling Machine Supplier evaluation has become more complex as global SMT lines face increasing product diversity, thinner boards, and higher reliability expectations. Rather than asking which technology is “best,” engineers now compare router, laser, and blade solutions based on stress behavior, long-term stability, and total production cost. This article summarizes real-world insights shared across SMT production environments.

⚙️ 라우터 구분 — Flexibility with Mechanical Control

Router systems remain widely used due to their adaptability to complex PCB outlines and mixed production.

Engineers commonly highlight:

- Strong flexibility for irregular shapes

- Controlled material removal that limits sudden stress

- Compatibility with both offline and online automation

Pain points include vibration management, tool wear, and dust control. In long-term operation, machine rigidity and spindle stability largely determine whether routing remains consistent over months rather than weeks.

🔥 레이저 구분 — Precision with Thermal Considerations

Laser depaneling is increasingly applied in high-density and thin PCB applications where mechanical stress must be minimized.

Key advantages discussed:

- No physical contact with the PCB

- Immaculate edges for sensitive components

- High repeatability on fine outlines

However, engineers also point out limitations:

- Thermal influence on certain substrates

- Higher equipment and maintenance costs

- Requirement for stable fume extraction

As a result, laser solutions are often reserved for high-value electronics rather than general-purpose SMT lines.

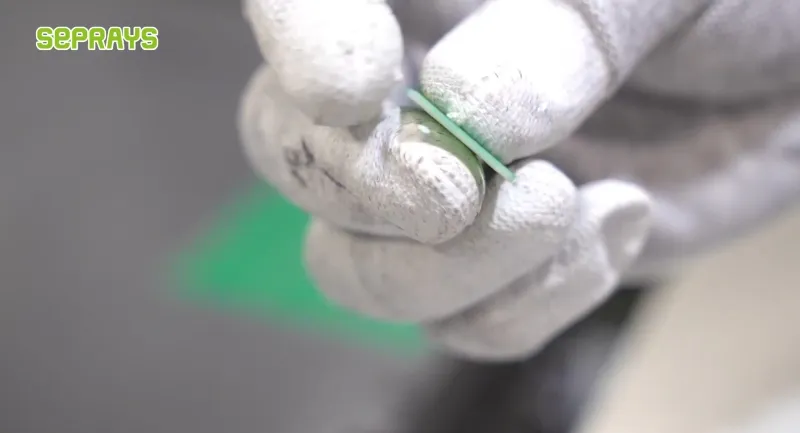

🪚 Blade Depaneling — Strength for Rigid Applications

Blade and saw-based systems are still relevant, particularly for thick or metal-core PCBs.

Typical use cases include:

- Aluminum-base boards

- Power electronics

- Low-density designs with generous edge clearance

While durable, blade systems introduce higher mechanical force and require careful alignment to avoid chipping or vibration-related defects.

📉 Cost Analysis — Technology vs. Long-Term Expense

Across different regions, engineers repeatedly emphasize that upfront cost rarely reflects total ownership cost.

Hidden expenses often include:

- Scrap caused by stress-related failures

- Rework discovered during functional or aging tests

- Downtime from tool changes or recalibration

- Increased inspection workload

Several SMT lines report that choosing a stable process—rather than the lowest-cost machine—reduced overall depaneling cost within one to two years.

🌍 Global Case Observations

- Germany: Automotive and industrial plants favor low-stress, traceable processes

- United States: EMS providers value flexibility and fast changeover

- Asia: High-volume factories balance speed with yield protection

- Mexico: Mixed production benefits from adaptable router systems

Despite regional differences, durability and consistency remain universal priorities.

🧩 How Engineers Compare Suppliers

Rather than focusing on brochures, experienced teams evaluate:

- Structural rigidity and component quality

- Stability of accuracy over time

- Application knowledge and process guidance

- Support for automation and traceability

- Proven results in similar PCB designs

This approach helps avoid short-term decisions that create long-term production risks.

Why Choose Seprays Group?

Seprays Group provides router, laser, and blade depaneling solutions designed with industrial durability, process stability, and long-term quality in mind. Our focus is on supporting real SMT production challenges through practical engineering and reliable system design.

If you would like to discuss your depaneling requirements or compare solution options, please contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)