설명

| 모델 | GAM320A |

|---|---|

| 유효한 크기로 절단 | 350*300mm |

| 절단 기능 | Tweening to straight line, L Shape, U Shape, Circle, and Arc |

| 프로세스 테이블 | 이중 테이블 |

| 반복 정밀도 | ±0.01mm |

| 절단 정밀도 | ±0.05mm |

| 최대 이동하는 속도 | XY: 1000mm/sec, Z: 600mm/sec |

| Max’s moving trip | X:810mm,Y:315mm Z:90mm |

| 스핀들의 속도 | MAX60,000rpm(조정 가능) |

| 절단 속도 | 1-100mm/s(조정 가능) |

| 운영 체제 | Windows10 |

| The program teaching method | 직관적으로 가르치는 것 CCD 컬러 이미지 입력 |

| 백업 프로그램 | USB 데이터 전송 |

| 제어 방법 | 귀 multi-axis 제어 시스템 |

| XYZ 축 운전 모드 | AC 자동 귀환 제어 장치 모터 |

| 의 크기를 맷돌로 가는 비트 | 0.8-3.0mm |

| 전압/전원 요구사항 | AC220V50/60Hz2.2KW 단상 |

| 압축 공기를 넣은 압력이 필요조건 | 0.6MPa,75L/min |

| 무게(W*D*H) | 1285*1340*1490mm 에서 입 |

| 체중 | 530KG |

| 먼지 수집가 | TS200 |

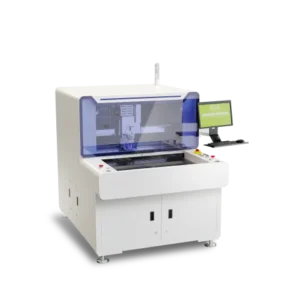

Product Introduction

Adopting a precision spindle, the machine reduces cutting stress and achieves high precision.

A high-speed CCD vision automatic calibration system ensures cutting accuracy and efficiency.

An anti-static spindle reduces static electricity during cutting, preventing short circuit damage to electronic boards.

The dual workstations allow for simultaneous board separation and manual board placement, reducing waiting time.

The Windows 10 operating system and user-friendly interface ensure stability and ease of use.

The GAM320A Automatic PCB Router is designed for flexible, high-precision PCB depaneling across diverse applications. It features a high-speed CCD vision alignment system to ensure accurate positioning and clean, consistent cuts on PCBs of virtually any shape. With a precision spindle that applies minimal cutting stress, it safeguards the integrity of sensitive components while delivering excellent performance.

Dual worktables enable simultaneous board loading and cutting operations, significantly reducing idle time. Operators can also merge these tables into a single large work area to handle oversized or complex panels. Supporting a wide range of software and hardware add-ons, the GAM 320A Automatic PCB Router adapts effortlessly to your workflow.

Available upgrades include safety light curtains, broken tool detection, spindle diameter monitoring, upper or lower dust collectors, and full MES integration. Dual spindle options are also offered for high-efficiency production.

특징

Operation Screen

- Simple settings for panel separation and milling cutter/fixture parameters.

- Processing efficiency and milling cutter usage data are clearly displayed.

- A history window facilitates operation log review.

- Equipped with milling cutter life management, maintenance alerts, and spindle speed settings.

CCD vision automatic calibration system

- Equipped with a high-speed CCD vision automatic calibration system.

- Cutting path simulation assists programming, ensuring accurate cutting paths.

- Full-sheet scanning and offline programming improve path editing efficiency.

Offline programming and full-sheet scanning

- Cutting programs can be edited offline and directly imported into the machine, improving utilization.

- Simpler, more user-friendly, automatic cutting path recognition.

- Scan and edit the entire PCB board to quickly modify the cutting path, improving programming efficiency.

- Selectable cutting line colors for easy identification of different PCB colors.

High-speed cutting spindle

- Imported high-speed, high-precision spindle.

- Low cutting stress, smooth board edges, and high precision.

- High-precision spindle speed of 80,000 rpm.

Maintenance reminder

- Settable maintenance time.

- Dust filter bag cleaning time.

- Timed reminder for operator maintenance.

Quick line change

- Recall existing programs to avoid fixture errors, enabling quick program recall and line change.

Application Cases

.png)

상품평

아직 상품평이 없습니다.