설명

| 모델 | GAM330AT |

|---|---|

| 유효한 크기로 절단 | 350*300mm |

| 로딩 방법 | 추적 납품 |

| 하역 방법 | 벨트 납품 또는 트랙 납품 |

| 전송 방법 | 진공 흡수 분사구 |

| 운동 방향 | 을 왼쪽 또는 오른쪽에서 왼쪽으로 |

| 절단 기능 | Tweening to a straight line, L shape, U shape, Circle, Arc |

| 프로세스 테이블 | 이중 테이블 |

| 반복 정밀도 | ±0.01mm |

| 절단 정밀도 | ±0.05mm |

| 최대 이동하는 속도 | XY:1000mm/sec Z:800mm/sec |

| Max’s moving trip | X:950mm,Y:440mm Z:90mm |

| 스핀들의 속도 | MAX:60000rpm 의 사용입니다(조정 가능) |

| 툴 유형 | 자동 툴 |

| 절단 속도 | 1-100mm/s(조정 가능) |

| 운영 체제 | 윈도우 10 |

| 교육 프로그램 모드 | 직관적으로 가르치는 것 CCD 컬러 이미지 입력 |

| 백업 프로그램 | USB 데이터 전송 |

| 제어 방법 | 정밀도 다중 축 제어 시스템 |

| XYZ 축 운전 모드 | AC 자동 귀환 제어 장치 모터 |

| 의 크기를 맷돌로 가는 도구 | 0.8-3.0mm |

| 전압/전원 요구사항 | AC220V50/60Hz4KW 단상 |

| 압축 공기를 넣은 압력이 필요조건 | 0.6MPa,160L/min |

| 크기(W*D*H) | 2105*1445*1,705mm 의 차 |

| 체중 | 800kg |

| 수집기 | TS300L |

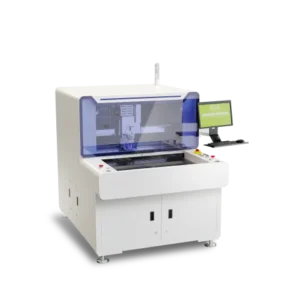

Product Introduction

This fully automatic online PCB depaneling machine features automatic loading, sorting, and discharging of finished and scrap PCBs, meeting the needs of automated production.

Equipped with a high-speed CCD vision alignment system, it is ideal for high-precision and high-capacity PCB depaneling.

A high-speed spindle is used for PCB cutting and depaneling, resulting in low stress, high precision, and adaptability to PCB shapes.

Dual-stage motion allows for simultaneous depaneling and placement, reducing waiting time, increasing production capacity, and improving operational efficiency.

It is suitable for depaneling small, multi-connected PCBs for applications such as mobile phones, digital cameras, GPS devices, PDAs, and modules.

A larger size option is available for depaneling large PCBs for applications such as digital TVs, PCs, workstations, and servers.

A variety of board collection options are available, achieving a fully automated, labor-saving operation.

The GAM 330AT PCB router is an advanced in-line automatic depaneling machine engineered for precision, speed, and seamless integration into modern PCB production lines. From loading to cutting and unloading, it provides full automation to meet a wide range of process requirements with minimal manual intervention.

Featuring a CCD vision positioning system, the GAM 330AT PCB router ensures exact alignment and offset correction for accurate cutting every time. A high-speed spindle with auto tool-change capability minimizes downtime and reduces static-related damage to delicate PCBAs. The patented flexible cleaning brush allows segmented use of the milling tool, effectively extending tool life.

This model is part of a high-efficiency series that includes dual-spindle options, such as the GAM320AD and GAM340AD. Optional add-ons include a clamping module, laser height checking, barcode reader, tool diameter detection, and MES customization.

특징

Maintenance reminders

- Settable maintenance schedule

- Dust filter bag cleaning schedule

- Regular reminders for operator maintenance

Quick line changeovers

- Recall existing programs to avoid fixture errors, enabling quick program recall and line changeovers

High utilization rate

- With over 30 years of independent software development, the board splitter utilizes stable and reliable software, eliminating bugs that could cause board failures.

Exclusive Features

- The depaneling machine features a one-piece welded design for stability and high strength.

- Made of cast aluminum, it resists oxidation, deformation, and deflection, ensuring a long lifespan and guaranteed precision.

Dust collection eliminates dust hazards

- Utilizes a high-power dust collector.

- HEPA-rated dust filtration.

- Equipped with a negative pressure detector to continuously monitor dust collection status.

- Equipped with a floating brush (invention patent number ZL201721620742.X) to enhance dust collection efficiency.

Centralized control system management

- Optional central control system: Centralized management and real-time monitoring via IP network.

- Remote device management: Remote monitoring via mobile app.

Application Cases

A real-world example of an online, fully automatic PCB splitter in action:

FAQ

어떤 서비스를 제공하는가?

We provide one-stop automated PCB depaneling solutions: laser, routing, punching, and V-CUT.

할 수 있는 기계의 핸들을 서로 다른 두께의 Pcb?

Yes, our machines are designed to handle a wide range of PCB thicknesses. We can provide customization and options to ensure smooth processing of both rigid and flexible boards.

어떤 유형의 훈련 당신은 당신을 위해 제공하겠습니까?

우리가 제공하는 포괄적인 사이트,교육을 덮는 기계 작동,유지보수,그리고 문제를 해결합니다. 우리는 또한 지속적인 기술지원을 통한 전화 및 이메일입니다.

무엇인 판매 후 서비스를 제공할 수 있습니까?

● Exclusive service:

We will give users feedback within 10 minutes on any problems they encounter when using the device, and establish a 1V1 exclusive after-sales service group for users.

● Remote service:

Provide users with a 7/24-hour hotline based on feedback on fault information, analyze, locate, and solve the fault through remote telephone support, remote login, and other methods.

● On-site service:

Arrive at the work site within 8 hours and solve the problem within 1 working day. 2-4 days of training on equipment safety, operation, and application. Any breach of contract will be handled by the contract provisions.

● Service locations:

우리는 영업 및 서비스 지원에서 31 개국 및 지역,해외 고객에게 응답하는의 현재 및 미래의 수요로 가능합니다.

● Benchmark service:

후속 호출한 후 각각 방문,비디오 튜토리얼+화에 대한 지침을 교체 부품 및 장비 유지 보수 무료 follow-up 달에 매년합니다. 우리는 계속하여 수집,사용자의 제안을 지속적으로 업데이트 및 반복하는 소프트웨어,사용자가 생산의 품질 및 효율성을 제공합 평생 유지 보수입니다.

응용 프로그램 영역

우리의 가진 이 솔루션은 널리 사용되는 산업에서 요구하는 높은-정밀도와 높은 효율성을 널리겠습니다.

핵심적인 응용 분야는 다음과 같습니다:

- Consumer Electronics – Smartphones, tablets, laptops, and wearables.

- Automotive Electronics – PCBs for ADAS, infotainment systems, and EV components.

- Medical Devices – Precision electronics in diagnostic and monitoring equipment.

- Telecommunications – Network and communication hardware.

- Industrial Electronics – Control systems, automation equipment, and IoT devices.

- Aerospace & Defense – High-reliability PCBs for avionics and military applications.

.png)

상품평

아직 상품평이 없습니다.