설명

| 모델 | GAM360AT |

|---|---|

| 유효한 크기로 절단 | 600*500mm |

| 로딩 방법 | 추적 납품 |

| 하역 방법 | 벨트 납품 또는 트랙 납품 |

| 전송 방법 | 진공 흡수 분사구 |

| 운동 방향 | 을 왼쪽 또는 오른쪽에서 왼쪽으로 |

| 절단 기능 | Tweening to a straight line, L shape, U shape, Circle, Arc |

| 프로세스 테이블 | 단일 테이블 |

| 반복 정밀도 | ±0.01mm |

| 절단 정밀도 | ±0.05mm |

| 최대 이동하는 속도 | XY:1000mm/sec Z:800mm/sec |

| Max’s moving trip | X:1040mm,Y:655mm,Z:90mm |

| 스핀들의 속도 | MAX:60000rpm 의 사용입니다(조정 가능) |

| 툴 유형 | 자동 툴 |

| 절단 속도 | 1-100mm/s(조정 가능) |

| 운영 체제 | 윈도우 10 |

| 교육 프로그램 모드 | 직관적으로 가르치는 것 CCD 컬러 이미지 입력 |

| 백업 프로그램 | USB 데이터 전송 |

| 제어 방법 | 정밀도 다중 축 제어 시스템 |

| XYZ 축 운전 모드 | AC 자동 귀환 제어 장치 모터 |

| 의 크기를 맷돌로 가는 도구 | 0.8-3.0mm |

| 전압/전원 요구사항 | AC220V50/60Hz4KW 단상 |

| 압축 공기를 넣은 압력이 필요조건 | 0.6MPa,200L/min |

| 크기(W*D*H) | 2309*1606*1717mm |

| 체중 | 930kg |

| 수집기 | TS300L |

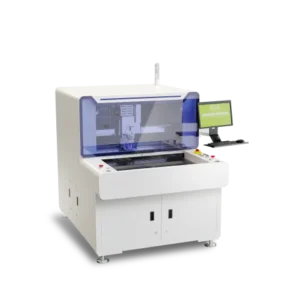

Product Introduction

A single workstation performs both cutting and circuit board placement, increasing productivity.

The vision camera features autofocus, eliminating the need for manual focus adjustment.

A high-speed spindle reduces cutting stress and achieves high precision, while an automatic tool changer enables automated operation.

The standard dust collector features dust detection and alarm functions to ensure effective dust collection.

MES connectivity allows for the integrated management system integration of production data and monitoring of equipment status.

The GAM360AT PCB separator is a high-performance, fully automatic PCB depaneling machine designed for precise and efficient board separation. From automatic loading, vision-based alignment, high-speed cutting, to smart unloading, the GAM360AT PCB separator streamlines your entire process while ensuring quality and repeatability.

A CCD vision positioning system allows for offset correction and alignment, which guarantees millimeter-level cutting accuracy. The GAM360AT PCB separator is equipped with a high-speed spindle featuring an auto tool-change function, minimizing static-related damage to sensitive PCBAs during processing.

Our patented flexible cleaning brush allows segmented use of the milling tool, significantly extending tool life. For higher throughput, Seprays also offers dual-spindle PCB separators함 GAM320AD, GAM330AD고 GAM340AD, tailored to your production scale.

Optional features include a clamping module, laser height checker, barcode reader, tool diameter detector, and MES integration.

Choose the GAM360AT PCB separator for reliable, scalable, and precision-driven PCB depaneling.

특징

Laser Height Measurement

- A laser height measurement module is installed to check whether the PCBA is placed at the correct height when placed in the jig. This prevents misalignment and damage during separation due to improper placement of the PCBA or small board fragments in the jig.

Quick Line Changeover

- Recall existing programs to avoid jig errors, enabling quick program recall and line changeover.

High Utilization Rate

- With over 30 years of independent software development, the depaneling machine utilizes stable and reliable software, eliminating board defects caused by bugs.

Exclusive Features

- The depaneling machine features a one-piece welded design for stability and high strength.

- Made of cast aluminum, it resists oxidation, deformation, and deflection, ensuring a long lifespan and guaranteed precision.

Dust collection eliminates dust hazards

- Utilizes a high-power dust collector.

- HEPA-rated dust filtration.

- Equipped with a negative pressure detector to continuously monitor dust collection status.

- Equipped with a floating brush (invention patent number ZL201721620742.X) to enhance dust collection efficiency.

Centralized control system management

- Optional central control system: Centralized management and real-time monitoring via IP network.

- Remote device management: Remote monitoring via mobile app.

Application Cases

The GAM360AT in-line, ultra-large PCB splitter can be connected to loaders, unloaders, and PCB collectors at the front and rear ends.

.png)

상품평

아직 상품평이 없습니다.