설명

| 모델 | ZM30-AP |

|---|---|

| 크기 | L*W*H=950*920*1750MM |

| 모 | 수직 |

| 체중 | 220KG |

| 색상 | 컴퓨터 백 |

| 전원 | AC220V300W |

| PCBA board separates direction | X or Y one-way can be divided into boards, and the angle can be arbitrarily adjusted |

| 작업압/튜브 직경 | -20~50℃ |

| 최소 거리의 부품에서 절단선 | 보다 크거나 같은 1.5mm |

| 최대 및 최소 길이드 | 250*250mm12*12mm |

| 는 최대 높이의 PCB components | PCBA 앞면과 뒷면을 높이 제한 합 less than15MM |

| Misoperation 보호 | grating sensor, safety door cover, and software multi-protection. |

| Parameter settingAccording | go to the size of the V-slot touch screen, direct input |

| 메모리 모듈 | 저장할 수 있습 50 의 그룹이 프로그램 |

| 분 효율 | 2s/나이프 |

| 날각 | 10-30 도(선택 가능) |

| 교체시간 | 15 분 |

| 나사 안내 | 실버 가이드 강제 나사 세 축 이동 플랫폼 |

| Maximum length and width of the assembly line | 650mm*250mm(주문을 받아서 만들어 질 수있다) |

| Thickness of the board | 0.4-3.5mm |

| 전과 가스 컷오프 기능 | 네 |

| 작동 모드 | manual release line, slitting, and feeding boards |

| 응용 프로그램의 범위 | Plug-in/패 |

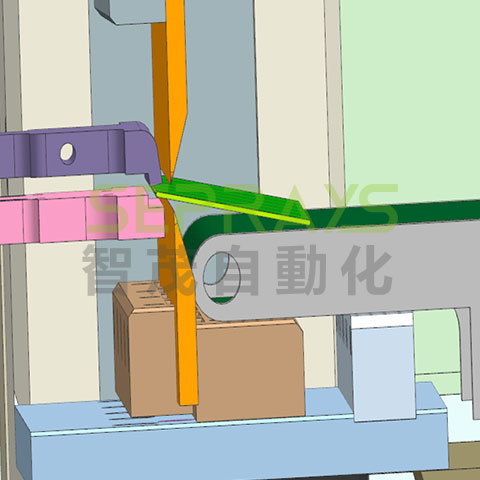

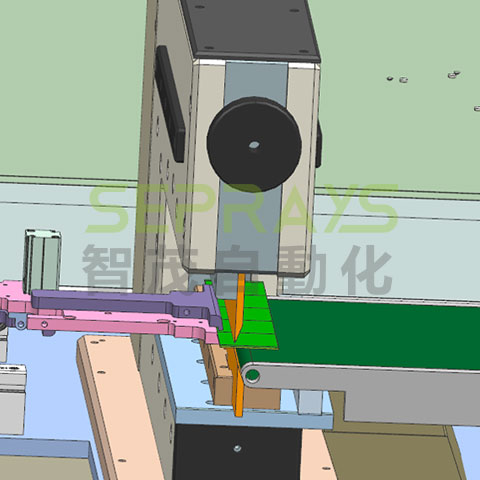

The ZM30-AP V-groove depaneling machine is a fully automated solution developed by SEPRAYS for efficient, precise, and safe V-groove PCB depaneling. From automatic feeding to cutting and discharging, this advanced system minimizes manual intervention and significantly boosts production efficiency.

Equipped with precision positioning technology, the ZM30-AP V-groove depaneling machine ensures exact alignment and cutting accuracy, protecting PCBA components and enhancing overall product quality. Its flexible material handling system—using suction cups and belt conveyors—accommodates a variety of PCB shapes and sizes with ease.

Integrated waste disposal keeps the workspace clean and streamlines production. Designed for continuous cycle operation, it’s ideal for high-volume manufacturing environments where speed and consistency are critical.

.png)

상품평

아직 상품평이 없습니다.