V-groove PCB depaneling is a common method used to separate pre-scored PCBs.

Choosing the right machine can significantly impact product quality, production speed, and equipment longevity.

In this article, we’ll break down the main types of V-groove PCB depaneling machines and what to consider when choosing the right one for your factory.

⚙️ Common Types of V-Groove PCB Depaneling Machines

🛠️ Moving-Blade Type

- Uses a rotary upper blade and a linear lower blade

- Produces very low stress, ideal for protecting solder joints

- Clean, burr-free edges—suitable for FR4 or component-loaded PCBs

- Comes with infrared safety curtains for operator protection

This is one of the most commonly used models across small to mid-volume electronics manufacturing.

✂️ Guillotine-Type (Straight-Blade)

- Dual pneumatic straight-blade design

- Cuts only short distances (≤2mm), reducing mechanical strain

- Ultra-low stress levels (down to 600μST)

- Works well with aluminum or copper-based boards

- Easy to operate, no training required

Perfect for high-hardness substrates and environments that prioritize simplicity.

💡 Multi-Blade Depaneling (for LED Strips)

- Equipped with six grouped blades for simultaneous multi-line cutting

- Reduces internal stress by 80%

- Prevents warping in aluminum-core PCBs

- Blade wobble <0.02mm, ensuring smooth, clean edges

A great choice for LED manufacturers or large-format light panel producers.

🧠 Seprays Featured Machines (For V-Scored Panels)

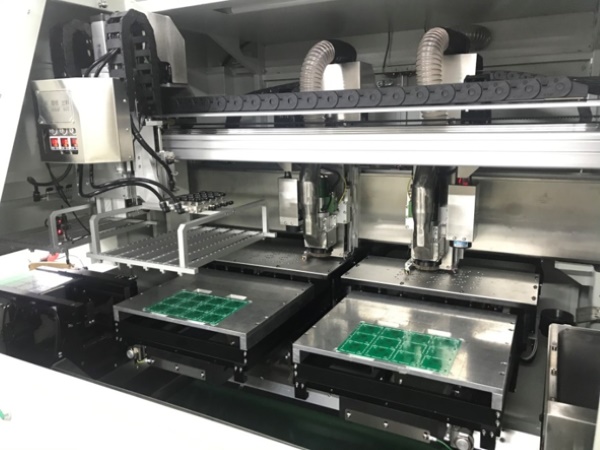

🔧 ZM30ASV / ZM300SV: Full-Automatic Online V-Groove Saw Depanelers

- Dual-direction cutting (X/Y axis)

- In-line conveyor system for unmanned operation

- Equipped with dust collection and quick-change blade modules

Ideal for high-throughput SMT lines that demand flexibility and cleanliness.

🎯 Vision-Based V-Groove Depaneling Machines

- Uses CCD vision correction for cutting accuracy (±0.05mm)

- Dual-table design enables simultaneous cutting and loading

- Great for applications that require tight tolerances and camera-based feedback

Recommended for precision electronics, such as mobile devices or automotive boards.

🔍 Other Depaneling Methods (For Comparison)

🌀 Router-Based Depaneling

- Seprays GAM386 represents this class

- Uses bottom-up milling, producing stress levels 1/100 that of manual snapping

- Best suited for boards with non-linear shapes or component-dense zones

🔬 Laser Depaneling

- High-end solution from Seprays

- Non-contact, zero-stress cutting

- No mechanical wear or blade changes required

- Ideal for ultra-thin or flexible PCBs

📌 How to Choose the Right Depaneling Machine

When selecting a V-groove PCB separator, consider:

- Board type: FR4, aluminum, copper, or flex

- Required throughput: Manual, semi-auto, or fully automated

- Stress sensitivity: Will you be cutting near BGA, QFN, or LEDs?

- Budget and scale: Consider long-term value, not just upfront cost

- Precision level: Some applications require CCD-guided systems

- Safety and cleanliness: Does your workspace need dust collection or noise reduction?

Still not sure? Reach out to our team—we’re here to help.

🌟 Why Choose Seprays Group?

Seprays has over 30 years of mechanical design and PCB process expertise.

We specialize in V-groove depaneling solutions tailored to every industry—from consumer electronics to automotive and LED lighting.

Here’s what makes us different:

✅ Global service network with 24/7 support

✅ Free equipment consultation and process matching

✅ In-house R&D with continuous software upgrades

✅ Competitive pricing without compromising on quality

Need help selecting the best V-groove depaneling machine for your needs?

Contact us today—we’ll provide you with expert guidance and a free quote.

.png)