Seprays-Jayden

Seprays-Jayden

2025-03-27 16:37:43

2025-03-27 16:37:43

15

15

In electronics manufacturing, companies need to make flexible circuits (FPCs) quickly, affordably, and with perfect consistency. Punching depaneling solves this challenge perfectly. It's fast, precise, and cost-effective - exactly what mass producers need. This method helps make the electronic parts in your phones, cars, and other devices quickly and reliably.

The punching depaneling process cleanly separates FPC/PCB panels through precisely controlled shearing. During operation, a custom-designed punch and die set - typically made of hardened tungsten steel with 5-10μm clearance - mechanically cut through the panel material with controlled force.

As the punch descends, the panel undergoes three distinct separation phases: initial elastic deformation, plastic flow into the die cavity, and final fracture propagation at an optimal 45° breakout angle. Modern systems achieve this with exceptional precision (±0.025mm) using servo-controlled presses operating at 80-120 strokes per minute, while integrated air blast systems (2-5bar) maintain clean cutting surfaces by removing debris between cycles.

The process is particularly effective for standard-shape FR4 boards (0.2-3.2mm thick) and flexible PI substrates (25-200μm), though it requires careful control of punch sharpness, dwell time (0.5-2ms), and counter pressure (0.1-0.3MPa) to minimize burrs and stress. While punching offers unmatched speed and cost-efficiency for high-volume production (over 10k units), its 0.15mm minimum feature size makes it less suitable for ultra-high-density designs compared to laser alternatives.

| Feature | Punching Depaneling | Laser Depaneling | Router Depaneling |

| Process Type | Mechanical stamping | Thermal ablation | Mechanical milling |

| Best For | Simple shapes, high volume | Complex shapes, fragile FPCs | Thick PCBs, prototypes |

| Speed | 100+ boards/minute | 10-30 boards/minute | 20-50 boards/minute |

| Precision | ±0.025mm | ±0.01mm | ±0.05mm |

| Min. Feature Size | 0.15mm | 0.05mm | 0.2mm |

| Material Thickness | 0.1-3.2mm | 0.025-2mm | 0.2-6mm |

| Setup Cost | High (custom dies required) | Medium | Low-Medium |

| Per-Unit Cost | Lowest at scale | Highest | Moderate |

| Stress on Board | Medium (mechanical impact) | Lowest (non-contact) | Medium (vibration) |

| Debris/Dust | Small particles | Smoke/vapor | Significant dust |

| Flex Circuit Suitability | Good (for thicker FPCs) | Excellent (all FPC types) | Fair (not for ultra-thin FPCs) |

| Tool Wear | Dies require sharpening | No tool wear | Bits require replacement |

| Best Application | Smartphone boards (high volume) | Medical wearables (delicate) | Automotive control units (thick) |

| FPC Characteristic | Ideal for Punching | Marginally Compatible | Not Recommended |

| Thickness | 0.2mm - 0.5mm | 0.1mm - 0.2mm (with carrier) | <0.1mm (too fragile) |

| Material Type | Standard PI (Polyimide) | Adhesive-based FPCs | LCP/PTFE (too soft/stretchy) |

| Copper Weight | 1oz (35μm) or less | 2oz (70μm) with die adjustment | >2oz (risk of delamination) |

| Circuit Density | Low-moderate (trace/space ≥0.15mm) | High-density with reinforced areas | Ultra-HDI (<0.1mm features) |

| Reinforcement | With stiffeners (FR4/PI) | Unreinforced with thick coverlay | Thin coverlay (<25μm) |

| Shape Complexity | Simple outlines (rectangles, basic curves) | Moderate complexity (R≥1mm curves) | Intricate contours (laser better) |

| Production Volume | High-volume (>10k units) | Medium-volume (5k-10k) | Prototypes (<1k) |

It's Super Fast

●Can cut 100+ boards per minute (lasers do 30, routers do 50).

●Works non-stop 24/7 with robots.

Cheaper for Big Orders

●Cost drops to less than 1 cent per board when making 50,000+.

●No expensive laser gas or router bits to replace.

Works Great for Common FPCs

●Perfect for circuits:0.2-0.5mm thick.

●With simple shapes (straight cuts or soft curves).

●That has stiff plastic supports.

●Makes identical cuts every time.

Easy to Use in Factories

●Fits right into automated production lines.

●Can switch to different designs in 5 minutes.

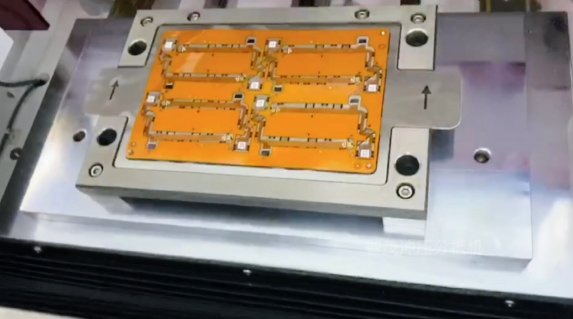

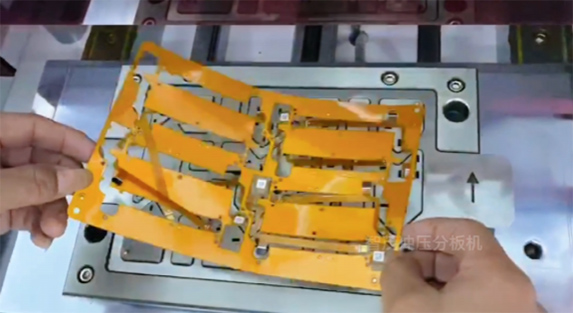

Seprays' ZM10T/15T PCB & FPC Punching Cutting Machine delivers high efficiency, capable of separating 6-8 FPCs/PCBAs per minute while ensuring a flawlessly flat and uniform product surface.

Conclusion

With speeds exceeding 100 boards per minute and costs dropping below one cent per unit for large batches, punching depaneling is the most efficient solution for mass production. It eliminates expensive laser gas and tool wear, ensuring long-term savings. Seprays' ZM10T/15T machine enhances productivity, cleanly separating up to eight boards per cycle. As demand for compact electronics rises, punching remains the best choice for scalable, high-precision manufacturing.

E-mail : sales@seprays.com

Tel : +86-0769-83284766

+86-13925527370

Address : 5th Floor, B2 Building Research Center Songshan Lake Intelligent Valley, Liaobu Town, Dongguan City, Guangdong Province, China