Offline Saw Blade PCB Depaneling Machine performance varies significantly across regions, and understanding these differences helps manufacturers benchmark efficiency, reduce tooling costs, and improve long-term reliability. In Europe—especially Germany and France—the focus often shifts toward industrial durability, consistent cutting quality, and stable long-term cost control rather than short-term output alone.

This article shares practical observations, production challenges, and field experiences gathered from various markets to encourage deeper discussion within the industry.

🏭 H1. Regional Expectations: Efficiency vs. Cutting Quality

Manufacturers in Germany often demand highly predictable cutting performance, prioritizing structural durability of the saw blade mechanism and minimization of micro-cracks along V-grooves. French electronics producers lean toward smooth processing of mixed-material PCBs and precise edge cleanliness to support optical post-inspection.

In contrast, Asian regions may pursue higher throughput with frequent batch changes. These differences create variations in machine workloads, maintenance cycles, and blade replacement intervals.

⚙️ H2. Key Pain Points Shared Across Regions

1. Tool Wear and Blade Life

Across all markets, saw blade wear remains one of the biggest concerns. European factories often calculate wear per panel area processed, while others track wear per operating hour.

Users report that improper feed speeds or aggressive V-cut depths lead to shortened blade life and inconsistent quality.

2. Dust Extraction and Environmental Regulations

Germany and France enforce stricter dust-emission standards. Offline saw machines that lack efficient negative-pressure systems often fail acceptance tests.

In regions with lighter regulations, dust buildup may lead to dimensional deviations after long production shifts.

3. Operator Skill Requirements

Because offline systems rely heavily on fixture accuracy and manual loading, operator training becomes essential. In European factories, fixture repeatability tolerance requirements tend to be tighter (<±0.1 mm).

📊 H3. Cost Analysis: How Each Region Manages Operational Expenses

🔹 Blade-Related Costs

- Europe: Optimized for blade longevity—operators frequently adjust feed settings to extend blade usage.

- Asia: Faster production speeds, more frequent blade changes, and higher operating speed tolerance.

🔹 Fixture Costs

French EMS companies frequently adopt multi-layer aluminum fixtures for better thermal stability.

Eastern European manufacturers prefer composite fixtures to reduce upfront cost.

🔹 Maintenance Costs

Preventive maintenance schedules differ:

- Germany: Typically, every 250–350 operating hours

- Middle East & Southeast Asia: Commonly every 500+ hours

🧪 H4. Case Observations From Different Regions

🟦 Case 1: Germany – Automotive Electronics

A Tier-1 supplier struggled with micro-fractures along ceramic-substrate PCBs. By lowering the feed rate and using a coated saw blade, they reduced the scrap rate by 32%.

🟥 Case 2: France – Industrial Control PCB Plant

A factory working with dense V-groove panels found that dust accumulation affected AOI clarity. After implementing dual-stage extraction, the AOI false-call rate dropped by 18%.

🟩 Case 3: Southeast Asia – High-Mix Production

Short production runs caused frequent fixture swapping. Introducing modular quick-lock fixtures improved changeover time from 12 minutes to 4 minutes.

🛠️ H5. Practical Solutions to Improve Performance

✔ Optimize Blade RPM vs. Feed Speed

A stable ratio leads to smoother edges and longer blade life. Regional best practice data suggests:

- High-density boards → slower feed

- Consumer electronics → balanced RPM + medium feed

✔ Reinforce Dust Extraction

European-grade systems with two-stage filtration significantly improve cut stability and machine cleanliness.

✔ Improve Fixture Design

Fixtures must maintain rigid support during saw blade entry and exit to avoid edge chipping—especially for thin PCBs (<0.6 mm).

✔ Record Tool Wear Data

Many factories now log blade replacement intervals to identify patterns tied to board materials.

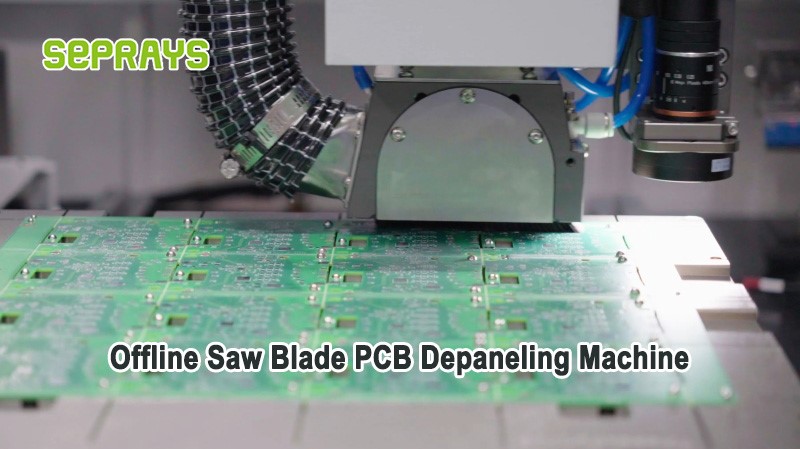

⭐ Why Choose Seprays Group?

Seprays focuses on precision engineering, industrial durability, and region-specific workflow optimization.

Our solutions are designed to support factories facing diverse regulatory environments, high-precision cutting demands, and long-term cost control requirements.

If you need technical consultation, application analysis, or sample testing, please contact us anytime.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)