PCB Depaneling Equipment has evolved rapidly over the past decade as electronics manufacturers strive for higher-density boards, tighter tolerances, and a wider range of materials. Across Europe, North America, and Asia, factories have adopted different depaneling technologies based on volume demands, quality requirements, component sensitivity, and long-term equipment cost.

This article shares real shop-floor observations, user pain points, cost considerations, and practical case insights to help engineers compare the four major methods: Router, Laser, V-Cut, and Saw Blade.

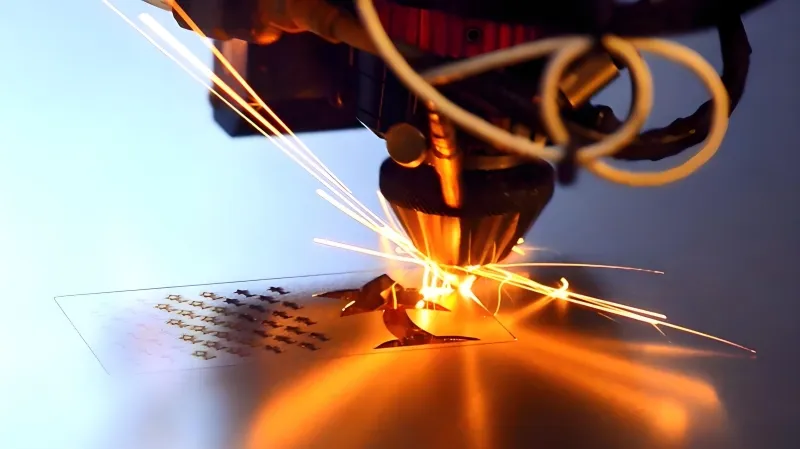

🔧 Router Depaneling — Flexible and Precise for Complex Designs

Router systems remain popular in automotive, industrial control, and IoT PCB assembly lines.

What technicians appreciate:

- Works well with irregular shapes, curved edges, and multi-panel arrays.

- Cutting stress is low, protecting fragile components and fine solder joints.

- Supports fixtureless routing, helpful for slightly warped or thin panels.

Challenges reported from European SMT lines:

- Bit wear affects edge smoothness if maintenance is inconsistent.

- Noise and dust require stable extraction systems.

- Spindle lifetime varies widely depending on material hardness and routing paths.

Best fit: Medium-to-high-precision PCBs with heavier components or complex outlines.

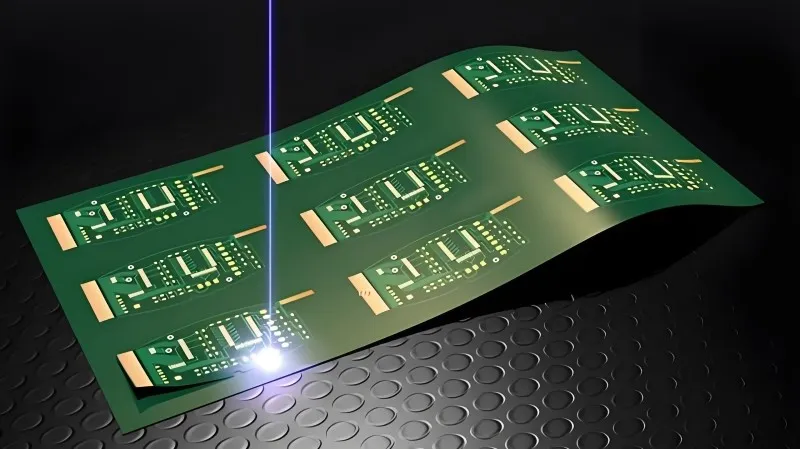

🔥 Laser Depaneling — Ultra-Clean but Higher Investment

CO₂ and UV lasers have seen rapid adoption in smartphones, medical, and high-density PCBs.

Advantages heard from German and French engineers:

- Zero mechanical stress, ideal for fragile components and microelectronics.

- Extremely clean edges, minimal burrs.

- Excellent for flex PCBs and ultra-thin substrates.

Limitations shared across global factories:

- Equipment cost is significantly higher.

- Cutting speed depends heavily on board thickness and resin composition.

- Potential carbonization on FR-4 requires optimized parameters.

Best fit: High value, high precision, thin or flexible PCBs where stress control matters.

✂️ V-Cut Scoring — Fast and Cost-Effective

V-Cut remains the most economical depaneling solution and is still widely used in household appliances, lighting, and general consumer electronics.

Why small factories like it:

- Very low operational cost.

- Easy to maintain, easy to automate in-line.

- Extremely fast throughput.

Common issues seen in Southeast Asian OEM lines:

- Higher mechanical stress, not ideal for components close to the score line.

- Limited to straight-line cuts only.

- Not suitable for thin PCBs or densely packed assemblies.

Best fit: Simple, rigid boards with generous component spacing.

⚙️ Saw Blade Depaneling — High Speed for Thick or Large Panels

Saw blade machines are favored in regions handling thick PCBs or power electronics.

Strengths observed in U.S. and Korean facilities:

- Robust cutting capability for thicker materials or high-strength laminates.

- High speed, good for mass production.

- Linear cutting accuracy is stable over long production cycles.

Pain points noted across factories:

- Burr formation requires post-processing if parameters are poorly tuned.

- Not suitable for complex curved outlines.

- Noise level is higher than routers or lasers.

Best fit: Large, thick, or industrial PCBs requiring high-speed straight cuts.

🌍 Regional Approaches to Technology Choice

Europe: Emphasis on precision, mechanical reliability, dust management, and long equipment lifespan.

North America: Balances throughput with flexibility; router and saw blade systems remain common.

East Asia: Strong demand for cost-performance; V-Cut and routers dominate in mid-range manufacturing, while mobile and medical sectors adopt lasers.

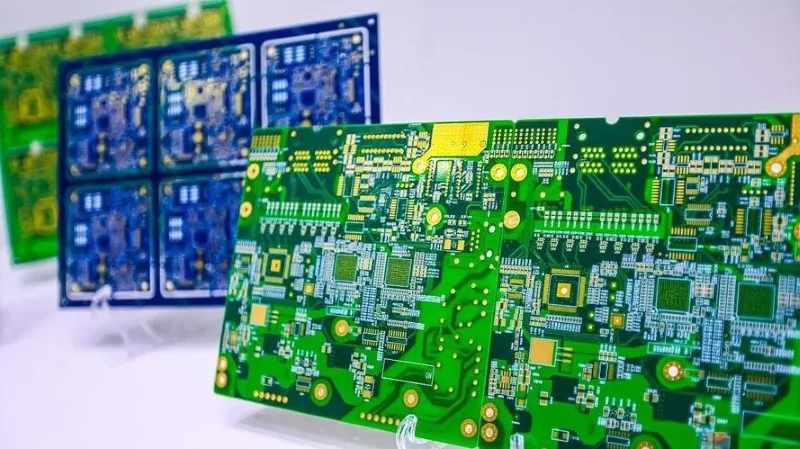

🧩 Which PCB Depaneling Equipment Works Best?

There is no universal winner — only the best fit for each factory’s priorities:

| Priority | Recommended Method |

|---|---|

| Lowest stress | Laser or Router |

| Fastest throughput | V-Cut or Saw Blade |

| Complex outlines | Router |

| Ultra-thin or FPC | Laser |

| Lowest cost | V-Cut |

| Thick boards | Saw Blade |

Engineers typically evaluate:

- PCB thickness and material

- Component sensitivity

- Panel shape

- Required edge quality

- Cost per cut and tool life

- Long-term maintenance burden

A practical approach is to test two or more methods directly on production panels to compare real-world results.

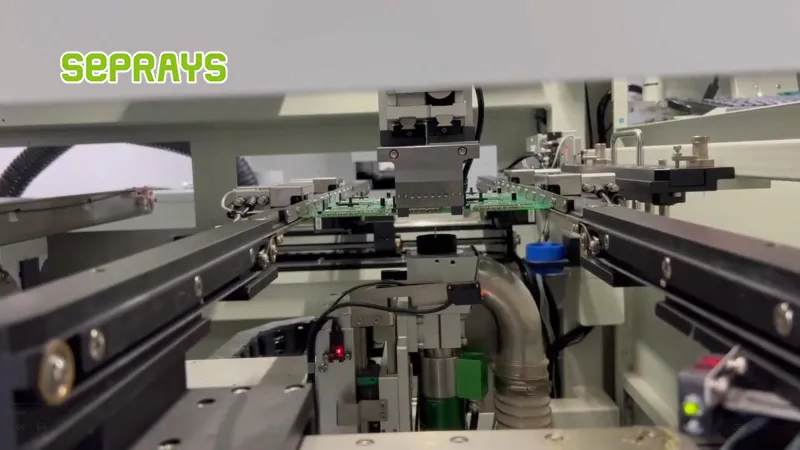

⭐ Why Choose Seprays Group?

Seprays provides globally proven depaneling solutions, including router, laser, V-Cut, and saw blade systems, supported by field experience from automotive, consumer electronics, and industrial OEMs.

If you need technical guidance, application testing, or equipment recommendations, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)