PCB Depaneling Market Trends are increasingly shaped by how EMS providers and OEMs respond to rising product complexity, reliability expectations, and cost pressure. While depaneling was once viewed as a secondary manufacturing step, many organizations now treat it as a quality-critical process with long-term implications. This article summarizes practical observations shared by engineers and production managers across global electronics manufacturing sectors.

📊 Market Shift: From Throughput to Process Stability

One noticeable trend across EMS and OEM discussions is a shift in evaluation criteria. Instead of focusing primarily on cutting speed, manufacturers increasingly emphasize:

- Process repeatability over long production runs

- Mechanical stress control

- Equipment durability under continuous operation

This change reflects growing awareness that depaneling-related issues often surface late—during reliability testing or field use—rather than immediately on the production floor.

🧩 EMS Perspective: Flexibility and Mixed Production

EMS providers face frequent product changeovers and wide PCB variation. Their main concern is not a single optimized setup, but how well a depaneling process adapts to different board designs.

Common EMS pain points include:

- Inconsistent quality when switching between products

- Increased setup time for complex panels

- Difficulty balancing cost efficiency with yield stability

As a result, EMS teams often favor solutions that allow parameter adjustment and stable performance across diverse applications.

🏭 OEM Perspective: Reliability and Lifecycle Cost

OEMs, particularly in automotive, industrial, and medical electronics, approach depaneling differently. Their focus extends beyond production to product lifecycle performance.

Key OEM considerations:

- Stress impact on long-term reliability

- Documentation and traceability requirements

- Predictable performance over years of operation

Several OEMs report that depaneling improvements reduced downstream validation failures without changing PCB materials or component suppliers.

💰 Cost Analysis: The Hidden Side of Depaneling

Across both EMS and OEM sectors, cost discussions increasingly include factors beyond equipment price.

Frequently mentioned hidden costs:

- Scrap from stress-induced micro-defects

- Rework discovered during functional or aging tests

- Additional inspection and cleaning processes

- Downtime from maintenance or recalibration

Many manufacturers now evaluate depaneling cost on a “per shipped board” basis rather than initial investment alone.

🌍 Regional Observations

- Europe: Strong emphasis on durability, traceability, and compliance

- North America: Balance between flexibility and throughput

- Asia: High-volume efficiency combined with gradual quality upgrades

- Emerging markets: Increasing awareness of long-term cost impacts

Despite regional differences, the underlying trend points toward a more disciplined depaneling process control.

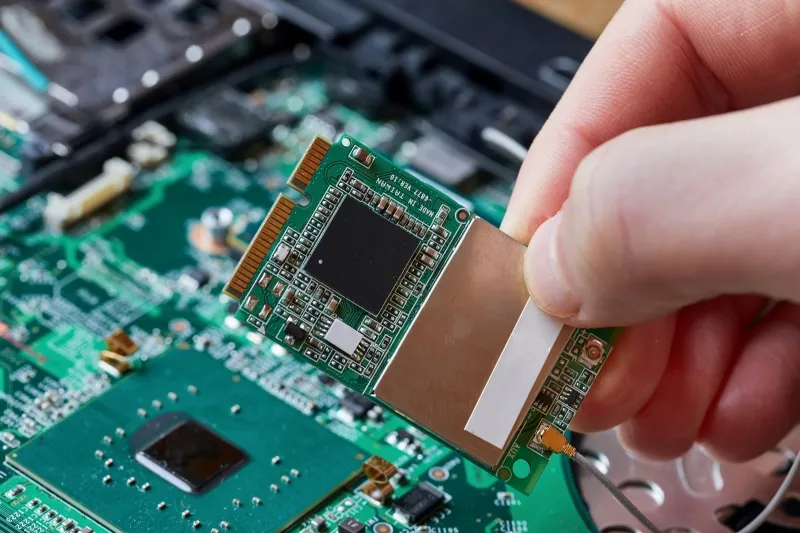

🛠️ Solutions Gaining Attention

Based on shared experience, manufacturers are increasingly interested in:

- Low-stress cutting technologies

- Robust mechanical structures for long-term stability

- Better dust and debris management

- Integration with MES and quality systems

Rather than replacing equipment frequently, companies aim to stabilize existing lines through better-matched depaneling solutions.

💬 Industry Discussion: What Comes Next?

Is depaneling becoming a strategic process step? Many engineers believe so. As PCBs continue to evolve, the ability to control stress, consistency, and durability during separation may become a key differentiator between average and high-performing manufacturing lines.

Why Choose Seprays Group?

Seprays Group supports EMS providers and OEMs with depaneling solutions designed around industrial quality, durability, and long-term process stability. Our approach focuses on real production challenges and practical engineering outcomes.

If you would like to discuss depaneling trends or evaluate solutions for your production environment, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)