PCB depaneling is a critical process in electronics manufacturing. It directly affects board quality and component reliability. This article analyzes seven common depaneling methods: manual breaking, die cutting, sliding-type depaneling, guillotine cutting, saw blade separation, milling (router) depaneling, and laser cutting.

1. Manual Depaneling

Manual depaneling includes two types: by hand or with tools such as pliers or fixtures.

Using fixtures improves efficiency compared to cutting with pliers. This method is often referred to as manual breaking.

Advantages:

- No equipment investment needed.

- Only basic tools (pliers, saw, sandpaper).

- Low cost per use.

- Suitable for simple depaneling tasks.

Disadvantages:

- Can leave burrs and uneven edges.

- Only suitable for boards without edge connectors or components.

- Not recommended for V-cut connections due to high mechanical stress.

- May damage components even on bare boards.

Manual depaneling is best for “stamp hole” connected PCBs with low-stress connections. For other connection types, this method is not advised.

2. Die Cutting

Die cutting uses specialized molds for fast, batch depaneling. It’s ideal for V-cut connected PCBs in medium production volumes.

Advantages:

- Very high efficiency.

- Ideal for mid-sized batch production.

Disadvantages:

- Requires expensive custom molds.

- High cutting stress may damage SMD components.

3. Sliding vs. Cutter Wheel Depaneling

Both methods are suitable for V-cut PCBs.

Sliding Type:

- Blade stays fixed; the operator pushes the board through.

- The lower blade drives the motion; the upper blade follows.

- Not widely used today.

Cutter Wheel Type:

- PCB stays still while a rotating blade moves side-to-side.

- Common and cost-effective method.

- Can introduce PCB stress, but good design can reduce this.

Advantages:

- Efficient and simple for straight cuts.

- Cost-effective for general use.

Disadvantages:

- May cause burrs and dust.

- Some mechanical stress during cutting.

4. Guillotine Depaneling

This method is similar to a paper cutter, using a straight blade to cut through V-cut PCBs.

Advantages:

- Easy to operate and safe.

- Low cost.

- Good for standard V-cut panels.

Disadvantages:

- Only suitable for V-cut panels.

- Blades require regular maintenance.

- Manual process limits productivity.

5. Saw Blade Depaneling

Uses high-speed rotating blades (e.g., diamond or carbide) to cut PCBs.

Works for both V-cut and stamp hole panels.

Advantages:

- Faster than manual depaneling.

- Suitable for thicker boards or those with some components.

- Good for small to mid-volume production.

Disadvantages:

- Can produce rough edges.

- Generates a lot of debris.

6. Milling (Router) Depaneling

Also known as CNC depaneling or routing. Uses a high-speed spindle and milling bit to cut through connection points. Common in PCB manufacturing.

Advantages:

- Cuts any shape, not just straight lines.

- Minimal mechanical stress on components.

- Smooth, precise cuts with no burrs.

- Low impact on PCB layout design.

Disadvantages:

- Generates dust, requiring dust removal systems.

- Expensive equipment.

- Fixtures must be custom-made for each product.

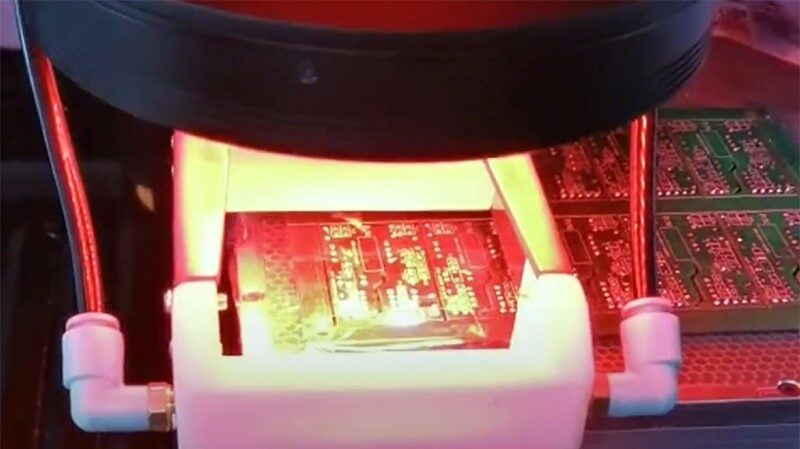

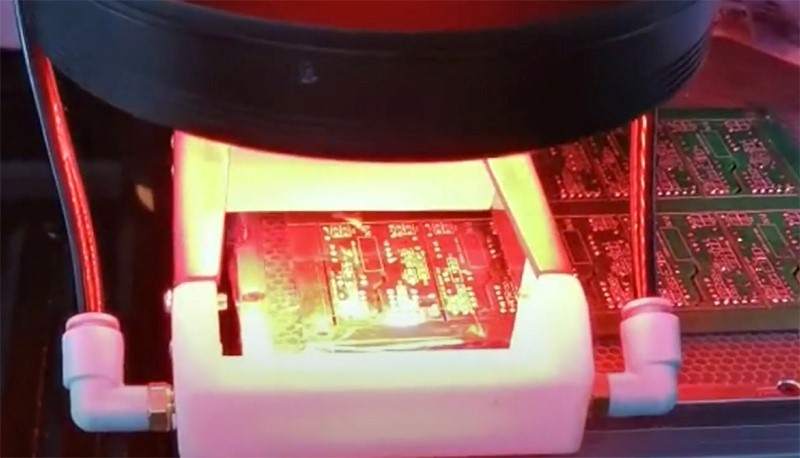

7. Laser Depaneling

Laser cutting uses high-energy beams to precisely separate PCBs. Suitable for complex, high-precision layouts or special materials.

Advantages:

- Ultra-high precision.

- No mechanical stress.

- No blade wear.

Disadvantages:

- High equipment cost.

- Less efficient on thick boards.

- Requires skilled operation.

Conclusion

Choose the right depaneling method based on your product’s precision, volume, and cost needs.

- Manual, saw blade, and die cutting work for low-cost or low-volume jobs.

- Milling and laser cutting are ideal for high-precision, high-density, or sensitive PCBs.

.png)