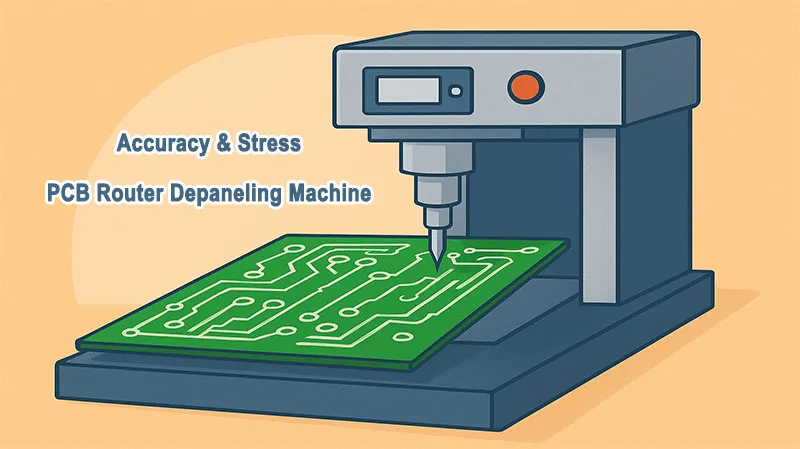

PCB Router Depaneling Machine selection has become a critical topic as PCB layouts grow denser and mechanical tolerances tighten. Across global SMT lines, engineers are no longer asking how fast a router can cut, but how consistently it maintains accuracy while minimizing mechanical stress over long production cycles. This article reflects shared lessons from real manufacturing environments rather than promotional claims.

🎯 Accuracy — Where Most Problems Begin

In router-based depaneling, accuracy is not defined by a single test cut. Engineers often report that machines perform well during trials but gradually drift during continuous production.

Common accuracy-related pain points include:

- Tool wear is causing a gradual kerf variation

- Z-axis inconsistency affecting cut depth on uneven panels

- Fiducial recognition errors on complex panel layouts

Experienced SMT teams emphasize that stable motion control, rigid machine frames, and consistent spindle behavior matter more than nominal speed specifications.

🧩 Stress Control — The Hidden Yield Factor

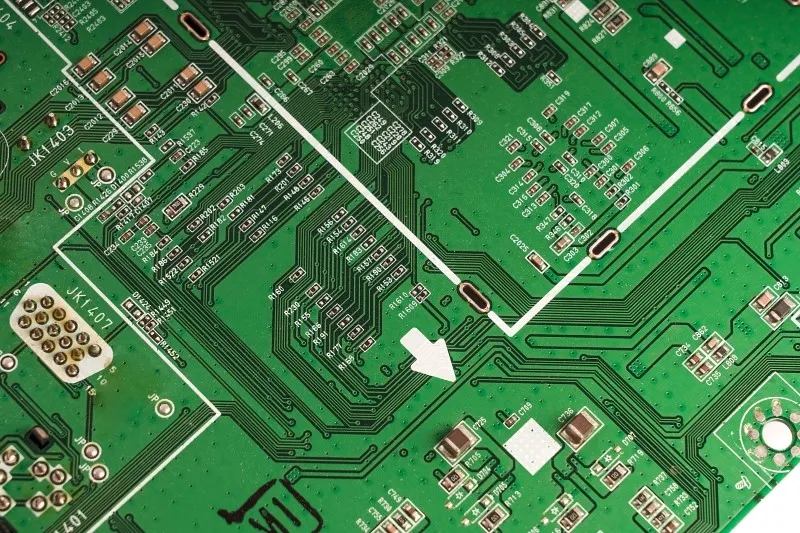

Mechanical stress introduced during routing is often invisible until it is revealed by functional testing or thermal cycling, at which point failures become apparent. Engineers working with fine-pitch components note that even small stress concentrations can affect solder joints near board edges.

Frequently observed issues:

- Micro-cracks near connectors and BGAs

- PCB edge deformation during high feed rates

- Stress accumulation on thin or partially supported panels

To mitigate these risks, many factories adjust routing sequences, reduce plunge force, and prioritize even load distribution instead of aggressive cutting strategies.

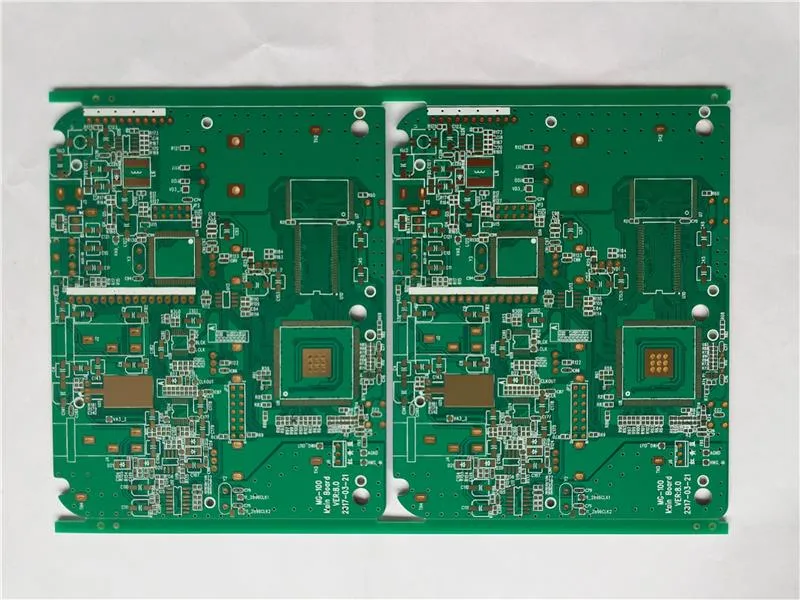

⚙️ Machine Design — Why Rigidity Matters

From an engineering perspective, machine rigidity defines long-term performance. Plants operating router depaneling systems 24/7 consistently report that lightweight structures amplify vibration, which directly affects accuracy and tool life.

Key design elements discussed by engineers include:

- Gantry stiffness and axis alignment

- Spindle balance at high RPM

- Controlled acceleration and deceleration profiles

Machines built with industrial-grade frames tend to maintain tolerance stability longer, reducing recalibration frequency.

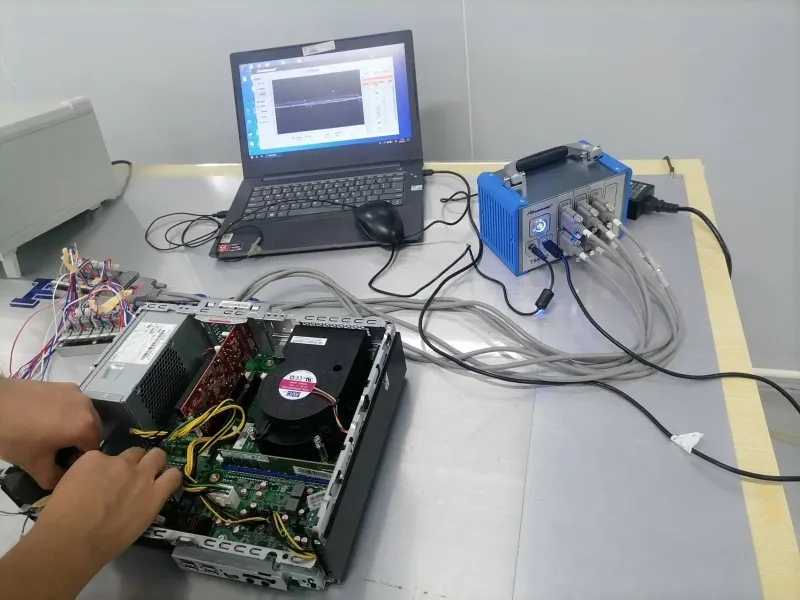

🧪 Material and Panel Variables

Not all PCBs behave the same under routing. Variations in material introduce additional challenges.

Examples include:

- FR4 panels generate fine dust that accelerates tool wear

- Aluminum-base PCBs require lower feed rates to avoid edge chipping

- Thin multilayer boards flexing during cutting

Factories often adapt routing parameters based on substrate type rather than applying a single universal recipe.

📉 Cost Analysis — Accuracy vs. Long-Term Expense

One lesson repeatedly shared across regions is that poor accuracy is expensive—even when the machine itself is inexpensive.

Hidden costs commonly identified:

- Increased scrap from marginal edge damage

- Rework caused by stress-related failures

- More frequent tool replacement

- Line stoppages for recalibration

Several SMT lines reported that improving routing stability reduced total depaneling cost despite slightly higher upfront investment.

🌍 Global Case Observations

- Germany: Automotive suppliers focus on stress control to ensure long-term reliability.

- United States: EMS providers value flexibility but demand repeatable accuracy across product changes.

- Southeast Asia: High-volume plants prioritize stability to maintain yield consistency at scale.

Across regions, engineers agree that accuracy must be sustained—not demonstrated once.

🛠 Practical Engineering Takeaways

Based on shared experience:

- Accuracy must be evaluated over time, not samples

- Stress control directly affects downstream reliability

- Rigid machine design reduces hidden quality losses

- Tool management is part of accuracy control

- Process tuning matters as much as machine selection

These insights continue to shape how router depaneling is applied in modern SMT lines.

Why Choose Seprays Group?

Seprays Group develops router depaneling solutions with a strong focus on industrial durability, structural rigidity, and stable cutting accuracy. Our designs emphasize long-term stress control and repeatable performance under continuous production conditions.

If you would like to discuss routing challenges or review cutting test results, please contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)