Specifications

| Item | ZM30-L Six-blade | ZM30-L Six-blade + 1.2M Platform | ZM30-L Six-blade + 2.4M Platform |

| Machine Dimensions (W × D × H) | 325 × 380 × 333 mm | 1200 × 506 × 333 mm | 2400 × 506 × 333 mm |

| Max. Depaneling Length | Unlimited | Unlimited | Unlimited |

| Depaneling Speed | 80, 120, 200, 400 mm/s | 80, 120, 200, 400 mm/s | 80, 120, 200, 400 mm/s |

| Depaneling Thickness | 0.2 – 5 mm | 0.2 – 5 mm | 0.2 – 5 mm |

| Power Supply | 230V / 50Hz (110V / 60Hz) | 230V / 50Hz (110V / 60Hz) | 230V / 50Hz (110V / 60Hz) |

| Machine Weight | 33 kg | 33 kg + 6 kg | 33 kg + 15 kg |

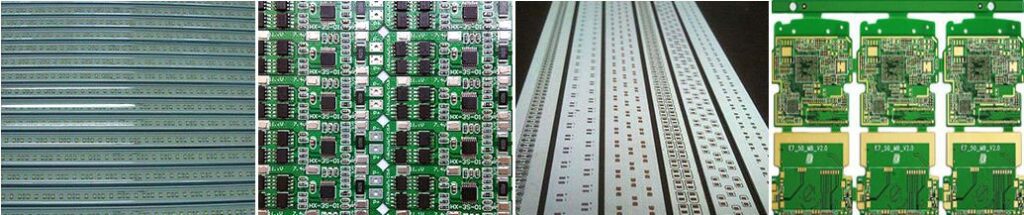

Application Examples

Suitable for various V-grooved PCBs, aluminum substrates, LED circuit boards, LED light strips, and more.

Mainly used in the LED, SMT, mobile phone, toy, and other electronics industries, as well as various other industries using circuit boards.

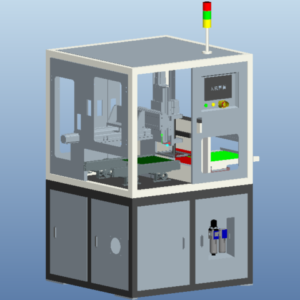

The ZM30-L Six-blade Aluminum Substrate Depaneling Machine is a cutting-edge solution designed for high-precision circuit board manufacturing, offering unmatched performance in stress control and cut quality. Engineered with SEPRAYS’ proprietary multi-stage cutting technology, it features three sequential cutting units—A, B, and C—to perform refined, step-by-step separation. This unique approach ensures exceptionally smooth cutting results.

By reducing cutting stress by over 80%, the ZM30-L Six-blade Aluminum Substrate Depaneling Machine significantly lowers the risk of board deformation, making it ideal for fragile or precision-demanding PCBs. The cutting edges remain flat and burr-free, and the board surface stays consistently smooth without any warping or twisting, fully meeting the rigorous standards of advanced electronic manufacturing.

Whether for consumer electronics, automotive systems, or aerospace-grade boards, the ZM30-L delivers precision, consistency, and a superior finish.

.png)

评价

目前还没有评价