Specifications

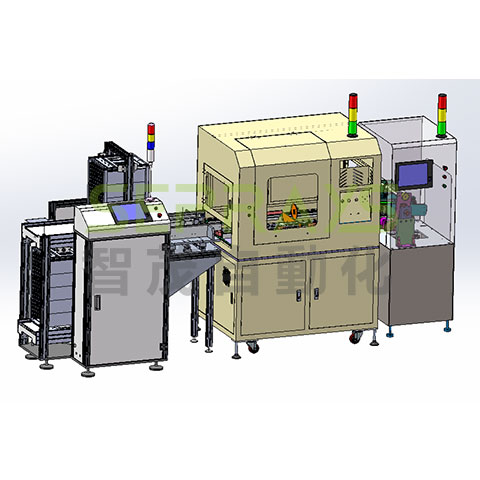

| Model | ZM30-X |

|---|---|

| Overall Dimension | 1750*1250*1700mm |

| Shape | Vertical |

| Weight | 600KG |

| Color | Computer white |

| Power supply | AC220V 4000W |

| Environmental | clean and dry environment, avoid humidity or high temperature. |

| Working air pressure/tube diameter | >0.6MP/8mm |

| Minimum distance of parts from the cutting line | greater than or equal to 1.5mm |

| Maximum and minimum board length | 300mm*260mm 12*12mm |

| Suction cup requirements | a single piece of a small board, at least one side of which is greater than 10 * 10m, and the space |

| Board inlet adjustment | direct input parameters, automatic adjustment |

| PCB board components’ maximum height | PCB reverse parts limit height 20mm, front limit height 35mm |

| Parameter setting | According to the size of the V-slot touch screen, direct input |

| Storage module | can store 50 groups of programs |

| Blade | high-speed steel knife |

| Blade angle | 10-30 degrees (selectable) |

| Die precision | 0.1mm |

| Partitioning efficiency | 15s/pcs (200*150mm) standard speed cut 8 knives for reference |

| Maximum length and width of the assembly line | 650mm*250mm |

| Splitting speed | 0-800mm/s |

| Suction cup manipulator motion control mode | stepping motor + guide rail + belt drive |

| Dust suction mode and power | 1500W under the knife group |

| Slitting thickness | 0 8-2. 5mm |

| Misoperation protection | triple protection of light grids, sensors, and software |

| Safety protection | emergency stop |

| Power failure and air cut-off function | Yes |

| Self-test function | power-on time monitoring, capacity monitoring, equipment fault information, and an automatic troubleshooting system |

| Work mode | automatic robot online slitting and feeding boards |

| Suitable | PCB boards after insertion/placement, double-direction V-groove |

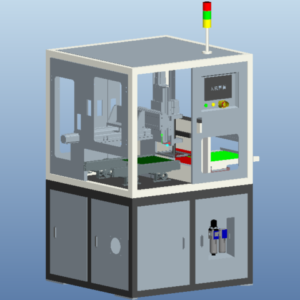

The ZM30-X V-groove machine by SEPRAYS is an advanced automatic depaneling solution capable of precise X and Y-axis slitting. Designed for high-throughput environments, it supports full in-line automation, eliminating the need for manual board release and significantly reducing labor costs.

This powerful machine handles various materials, including aluminum substrates (300–1500mm), copper substrates, FR4, and fiberglass boards, delivering smooth, burr-free cuts. With tool-free changeover capabilities, operators can easily switch knife molds and suction cups for different board types, enabling efficient unmanned operation and minimizing downtime.

Ideal for consumer electronics, home appliances, automotive electronics, and more, the ZM30-X V-groove machine meets the needs of complex, multi-connected PCB depaneling tasks with precision and speed.

.png)

评价

目前还没有评价